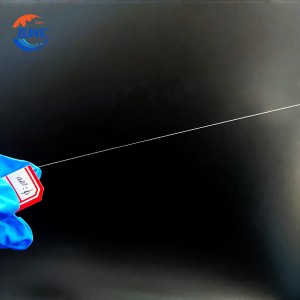

Sapphire Optical Fiber Light Transmission Extreme Environments

Detailed Diagram

Introduction

Sapphire Optical Fiber is a high-performance single-crystal transmission medium developed for optical applications that demand exceptional durability, temperature resistance, and spectral stability. Manufactured from synthetic sapphire (single-crystal aluminum oxide, Al₂O₃), this fiber delivers consistent optical transmission from the visible to mid-infrared regions (0.35–5.0 μm), far surpassing the limits of traditional silica-based fibers.

Because of its monocrystalline structure, sapphire fiber exhibits outstanding resistance to heat, pressure, corrosion, and radiation. It enables stable signal transmission in harsh and reactive environments where ordinary fibers would melt, degrade, or lose transparency.

Distinctive Characteristics

-

Unmatched Thermal Endurance

Sapphire optical fibers retain optical and mechanical integrity even when exposed to temperatures exceeding 2000°C, making them suitable for in-situ monitoring in furnaces, turbines, and combustion chambers. -

Wide Spectral Window

The material supports efficient light transmission from ultraviolet to mid-infrared wavelengths, allowing flexible use in spectroscopy, pyrometry, and sensing applications. -

High Mechanical Robustness

The single-crystal structure provides high tensile strength and fracture resistance, ensuring reliability under vibration, shock, or mechanical stress. -

Exceptional Chemical Stability

Resistant to acids, alkalis, and reactive gases, sapphire fibers function effectively in chemically aggressive atmospheres, including oxidizing or reducing environments. -

Radiation-Hardened Material

Sapphire is inherently immune to darkening or degradation under ionizing radiation, making it ideal for aerospace, nuclear, and defense operations.

Manufacturing Technology

Sapphire optical fibers are typically produced using Laser-Heated Pedestal Growth (LHPG) or Edge-defined Film-fed Growth (EFG) methods. During growth, a sapphire seed crystal is heated to form a small molten zone and then drawn upward at a controlled rate to form a fiber with uniform diameter and perfect crystal orientation.

This process eliminates grain boundaries and impurities, resulting in a defect-free single-crystal fiber. The surface is then precisely polished, annealed, and optionally coated with protective or reflective layers to enhance performance and durability.

Application Fields

-

Industrial Temperature Sensing

Used for real-time temperature and flame monitoring in metallurgical furnaces, gas turbines, and chemical reactors. -

Infrared and Raman Spectroscopy

Delivers high-transmission optical paths for process analysis, emissions testing, and chemical identification. -

Laser Power Delivery

Capable of transmitting high-power laser beams without thermal deformation, ideal for laser welding and material processing. -

Medical & Biomedical Instruments

Applied in endoscopes, diagnostics, and sterilizable fiber probes that require high durability and optical precision. -

Defense and Aerospace Systems

Supports optical sensing and telemetry in high-radiation or cryogenic conditions such as jet engines and space propulsion units.

Technical Data

| Property | Specification |

|---|---|

| Material | Single-Crystal Al₂O₃ (Sapphire) |

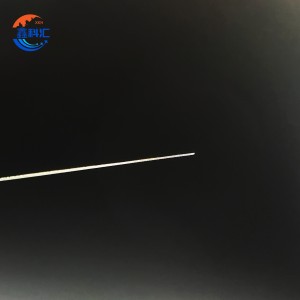

| Diameter Range | 50 μm – 1500 μm |

| Transmission Spectrum | 0.35 – 5.0 μm |

| Operating Temperature | Up to 2000°C (air), >2100°C (vacuum/inert gas) |

| Bending Radius | ≥40× fiber diameter |

| Tensile Strength | Approx. 1.5–2.5 GPa |

| Refractive Index | ~1.76 @ 1.06 μm |

| Coating Options | Bare fiber, metal, ceramic, or protective polymer layers |

FAQ

Q1: How is sapphire fiber different from quartz or chalcogenide fibers?

A: Sapphire is a single crystal, not an amorphous glass. It has a much higher melting point, wider transmission window, and superior resistance to mechanical and chemical damage.

Q2: Can sapphire fibers be coated?

A: Yes. Metal, ceramic, or polymer coatings can be applied to improve handling, reflection control, and environmental resistance.

Q3: What is the typical loss of sapphire optical fiber?

A: Optical attenuation is approximately 0.3–0.5 dB/cm at 2–3 μm, depending on surface polish and wavelength.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.