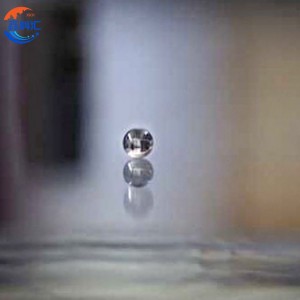

Sapphire Balls High-Precision Components Bearings Optical High Compressive

Detailed Diagram

Overview of Sapphire Balls

We specialize in producing high-precision sapphire and ruby balls with diameters ranging from 0.60 mm to 150 mm. Made from synthetic single-crystal aluminum oxide (Al₂O₃), these spheres offer:

-

Exceptional hardness (Mohs 9, second only to diamond)

-

Outstanding wear resistance

-

Superior chemical stability

Thanks to these properties, sapphire balls deliver long-lasting performance even in extreme conditions.

Widely used in precision engineering, fluid control, optics, and measurement technologies, they outperform steel, glass, and ceramics by combining durability, chemical inertness, and optical transparency.

Material Properties

-

Material: Synthetic Sapphire / Ruby (Al₂O₃)

-

Hardness: Mohs 9 (extremely hard, scratch-resistant)

-

Melting Point: 2045 °C (3713 °F)

-

Refractive Index: No = 1.768, Ne = 1.760

Key Features:

-

High resistance to mechanical wear

-

Chemically inert to most acids, alkalis, and solvents

-

Wide optical transmission range (200 nm – 5 μm)

-

Stable under high pressure and thermal cycling

-

Available in multiple diameters and tolerances upon request

Applications

-

Special Bearings: Low-friction, long-life components in lubrication-limited systems

-

Medical & Chemical Devices: Resistant to aggressive reagents, ensuring reliability

-

Flow Control: Precision balls in pumps, valves, and flow meters

-

Writing Instruments: Precision tips for fountain pens and ballpoint pens

-

Optical & Measurement Tools: Gauges, scanners, and fiber optic connectors requiring accuracy and stability

Specifications

| Property / Parameter | Specification |

|---|---|

| Diameter Range | 0.60 mm – 150 mm |

| Diameter Tolerance | ± 2 nm max. |

| Roundness Tolerance | < 0.0005 mm |

| Surface Quality | 10/5 max. (MIL-PRF-13830B) |

| Roughness (Ra) | ≤ 2 nm |

| Refractive Index | No = 1.768, Ne = 1.760 |

| Hardness | Mohs 9 |

| Melting Point | 2045 °C (3713 °F) |

| Inspection | 100% microscopic inspection |

| Packaging | Blister tray, glass bottles, or vacuum-sealed bags |

| Cleanroom Standard | Fully inspected and packaged in cleanroom conditions |

Product Advantages

-

Durability: Mohs 9 hardness ensures extremely long service life

-

Chemical Stability: Performs reliably in corrosive environments

-

Precision: Ultra-tight tolerances (±2 nm, roundness <0.0005 mm)

-

Versatility: Applied across aerospace, semiconductor, biomedical, and electronics industries

-

Customization: Wide range of sizes, tolerances, and finishes available

FAQ

Q1: What is a sapphire ball?

A sapphire ball is a precision sphere made from single-crystal Al₂O₃. It combines extreme hardness, wear resistance, chemical stability, and optical transparency, making it suitable for industrial, optical, and scientific use.

Q2: How do sapphire balls compare to steel or ceramic balls?

-

Hardness: Mohs 9 (second only to diamond)

-

Chemical Resistance: Inert to most acids, alkalis, and solvents

-

Temperature Stability: Up to 1900 °C in air, 2000 °C in inert atmosphere

-

Optical Transparency: Transmission from UV (0.2 μm) to IR (5.5 μm)

-

Non-Magnetic & Electrically Insulating

Q3: What are the main applications?

-

Industrial Bearings

-

Medical Devices (valves, pumps, biocompatible parts)

-

Semiconductor & Electronics (spacers, wear-resistant components)

-

Optics & Lasers (calibration, light transmission)

-

Scientific Research (high-pressure cells, microfluidics, extreme testing)

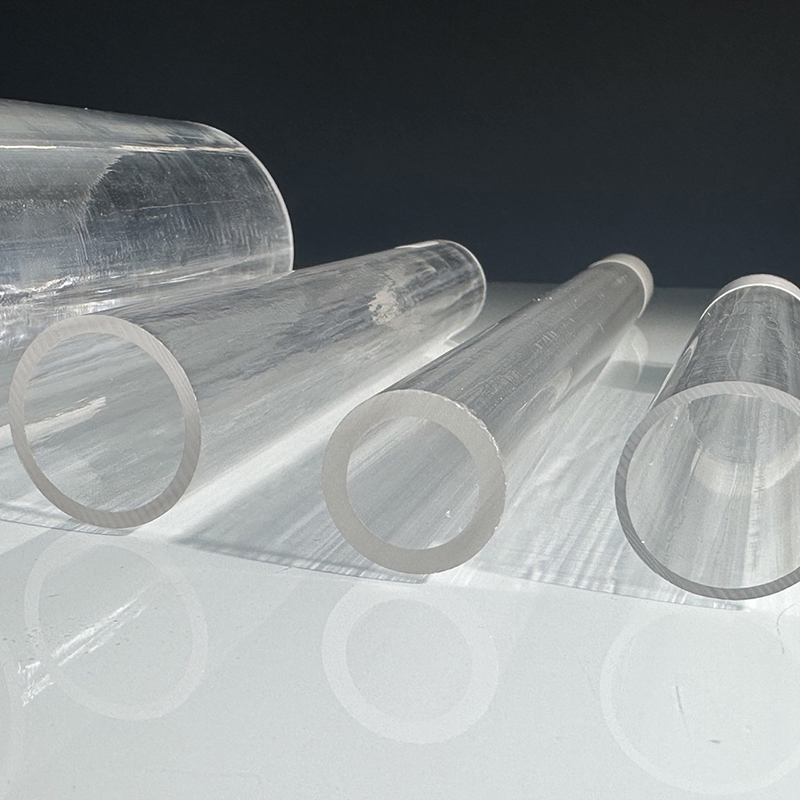

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.