Multi-Wire Diamond Wire Saw for High-Precision Slicing of Hard and Brittle Materials

Detailed Diagram

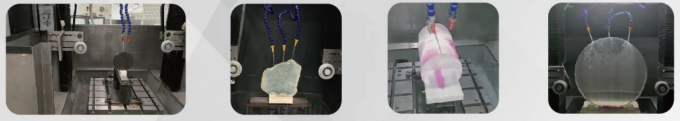

Overview

The TJ3545 Dual-Workstation Swing-Up Multi-Wire Diamond Wire Saw is engineered to meet high-throughput slicing demands for hard and brittle materials. Designed around the goals of productivity, precision, stability, and application versatility, this model integrates a dual-workstation layout, multi-wire diamond wire cutting, and a swing-cutting mechanism. It supports both large-format slicing and ultra-thin cutting on a single platform, enabling one machine to serve multiple production tasks and improve overall equipment utilization in continuous, high-volume operations.

Applications and Materials

TJ3545 is well suited for slicing a wide range of hard, brittle, or high-value materials, including:

-

Silicon carbide (SiC)

Sapphire

Advanced ceramics

Quartz stone

Semiconductor materials

Optical glass

Laminated glass

Precious metals

These materials typically present challenges such as high hardness, brittleness, chipping sensitivity, and strict requirements for thickness tolerance and surface quality. TJ3545 addresses these demands with a swing-up cutting process, servo-driven motion control, and stable tension regulation to deliver both efficiency and consistent slicing quality.

Swing-Up Cutting Method: More Stable Cutting for Hard and Brittle Materials

TJ3545 adopts a swing-up cutting approach. During cutting, the wire system runs in a stable path while the workbench swings upward to complete the cutting trajectory. This method helps optimize the cutting force distribution, reduces localized impact on brittle workpieces, and improves slice consistency and flatness. The swing angle is ±8°, and the swing speed is 0.83°/s, allowing the process to be tuned according to material hardness, target thickness, and surface quality requirements.

Dual-Workstation Design: Higher Throughput and Better Line Efficiency

With two workstations, TJ3545 supports parallel operation and flexible scheduling:

-

One workstation can run while the other is being loaded or prepared, reducing idle time.

-

Different materials or thickness jobs can be arranged across the two stations for faster changeover and better production flow.

This dual-station architecture significantly improves productivity, especially in multi-product, fast-delivery manufacturing environments.

Full Servo System and Tension Control: Precision and Repeatability

The machine features a full servo motor system combined with stable tension control, delivering smooth motion response, accurate feed behavior, and highly repeatable cutting performance. Key capability indicators include:

-

Cutting accuracy: 0.01 mm

-

Maximum cutting tension: 110 N (minimum setting increment 0.1 N)

Stable, controllable tension is critical for multi-wire slicing. It helps maintain process consistency during long runs, speed changes, or load fluctuations, supporting higher yield and batch-to-batch stability.

High-Speed Multi-Wire Capability: Built for Productivity

To maximize throughput, TJ3545 provides strong performance in wire speed and wire diameter compatibility:

-

Wire running speed: up to 1500 m/min (MAX)

-

Diamond wire diameter: 0.1–0.5 mm

-

Line storage capacity (supply wheel): 20 km (based on 0.25 mm wire)

This broad capability window allows the machine to be configured for high-speed production slicing or for finer cutting requirements where smaller wire diameters and controlled cutting conditions are preferred.

Cutting Range and Feed Control: From Ultra-Thin to Standard Slices

TJ3545 supports a cutting thickness range of 1.4–50 mm, with a cutting feed speed of 0.01–10 mm/min, enabling optimized parameter matching (wire speed, tension, and feed rate) across diverse applications. The vertical lifting stroke of the workstation is 350 mm, improving adaptability to different workpiece heights and fixturing needs.

Production-Oriented Utilities: Coolant System and Long-Run Operation

A 300 L water tank is integrated to support cooling, debris removal, and stable long-duration operation. The machine supports high-efficiency anti-rust cutting fluid, enhancing corrosion protection and process cleanliness in extended production cycles. A closed structure and visual operation interface also help improve safety and reduce fluid splash in the workshop environment.

Specification

| Item | Specification |

|---|---|

| Maximum workpiece size | φ320 × 430 mm |

| Main roller coating diameter (single shaft) | φ225 × 450 mm (five main rollers) |

| Wire running speed | 1500 m/min (MAX) |

| Diamond wire diameter | 0.1–0.5 mm |

| Line storage capacity (supply wheel) | 20 km (based on 0.25 mm wire) |

| Cutting thickness range | 1.4–50 mm |

| Cutting accuracy | 0.01 mm |

| Vertical lifting stroke (workstation) | 350 mm |

| Cutting method | Workbench swings upward while the diamond wire remains stationary |

| Cutting feed speed | 0.01–10 mm/min |

| Water tank | 300 L |

| Cutting fluid | Anti-rust high-efficiency cutting fluid |

| Swing angle | ±8° |

| Swing speed | 0.83°/s |

| Maximum cutting tension | 110 N (minimum setting increment: 0.1 N) |

| Workbenches | 2 |

| Power supply | Three-phase five-wire AC 380 V / 50 Hz |

| Total machine power | ≤ 46 kW |

| Main motor (water-cooled) | 7.5 × 3 kW |

| Wiring motor | 0.75 × 2 kW |

| Workbench swing motor | 1.5 × 2 kW |

| Tension control motor | 1.5 × 2 kW |

| Workbench lifting motor | 0.4 × 2 kW |

| Wire release & collection motor (water-cooled) | 7.5 × 2 kW |

| External dimensions (excluding rocker arm box) | 2750 × 2340 × 2670 mm |

| External dimensions (including rocker arm box) | 2900 × 2340 × 2850 mm |

| Machine weight | 6000 kg |

TJ3545 Dual-Workstation Swing-Up Multi-Wire Diamond Wire Saw FAQ

Q1: What materials is the TJ3545 designed to cut?

A: The TJ3545 is designed for slicing hard and brittle materials such as silicon carbide (SiC), sapphire, advanced ceramics, quartz stone, semiconductor materials, optical glass, laminated glass, and precious metals. It is suitable for both large-format and ultra-thin slicing applications.

Q2: What does “dual-workstation” mean and what is the benefit?

A: Dual-workstation means the machine has two independent workbenches. This enables parallel production or alternating loading and cutting, reducing idle time and significantly improving throughput and equipment utilization.

Q3: What is “swing-up cutting” and why is it used?

A: Swing-up cutting refers to a process where the workbench swings upward during cutting while the diamond wire path remains stable. This helps distribute cutting forces more evenly, improving stability and reducing chipping risks on brittle materials, while supporting better slice consistency.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.