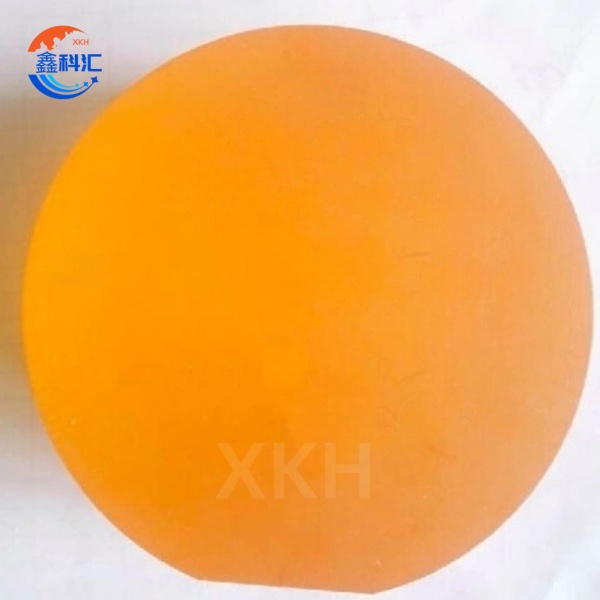

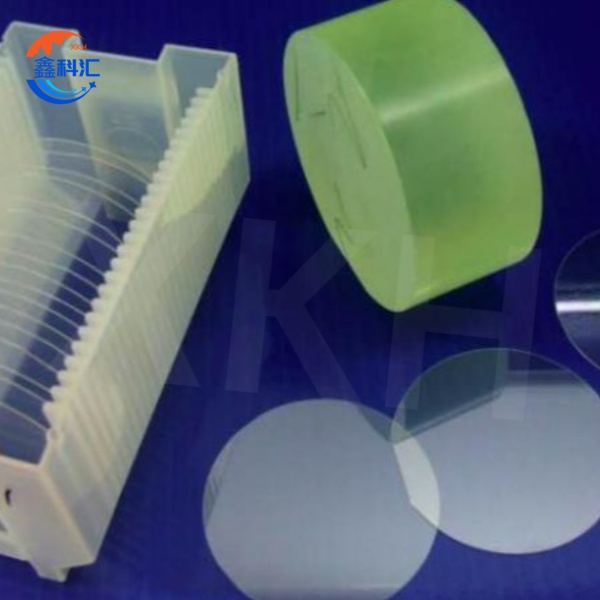

LiTaO₃ Ingots 50mm – 150mm Diameter X/Y/Z-Cut Orientation ±0.5° Tolerance

Technical parameters

Specification |

Conventional |

High Precision |

Materials |

LiTaO3(LT)/ LiNbO3 wafers |

LiTaO3(LT)/LiNbO3 wafers |

Orientation |

X-112°Y,36°Y,42°Y±0.5° |

X-112°Y,36°Y,42°Y±0.5° |

Parallel |

30″ |

10'' |

Perpendicular |

10′ |

5' |

surface Quality |

40/20 |

20/10 |

Wavefront Distortion |

λ/4@632nm |

λ/8@632nm |

Surface Flatness |

λ/4@632nm |

λ/8@632nm |

Clear Aperture |

>90% |

>90% |

Chamfer |

<0.2×45° |

<0.2×45° |

Thickness/Diameter Tolerance |

±0.1 mm |

±0.1 mm |

Maximum dimensions |

dia150×50mm |

dia150×50mm |

LiTaO₃ Ingot - Key Characteristics

1. Superior Piezoelectric & Acoustic Performance

High piezoelectric coefficient (d₃₃~8 pC/N): Outperforms LiNbO₃ (~6 pC/N), enabling high-frequency SAW/BAW filters with ultra-low insertion loss (<1.2 dB) for 5G RF frontends.

Strong electromechanical coupling (K²~0.5%): Enhances bandwidth and efficiency for Sub-6GHz and mmWave communication systems.

2. Exceptional Thermal Stability

High Curie temperature (600°C): Maintains stable piezoelectric performance across -50°C to 300°C, ideal for automotive electronics and industrial sensors.

Low thermal expansion coefficient (7.5×10⁻⁶/K): Minimizes thermal drift in precision devices.

3. Optical & Chemical Robustness

Broadband transparency (400-5000 nm): >70% transmittance for IR windows and electro-optic modulators.

Chemical inertness: Resists acids/alkalies, suitable for aerospace and defense applications in harsh environments.

4. Customization Capabilities

Orientation engineering: X/Y/Z-cut ingots (±0.5° tolerance) for tailored piezoelectric/optical properties.

Doping optimization: Mg-doping for optical damage resistance; Zn-doping for enhanced piezoelectric response.

LiTaO₃ Ingot - Primary Applications

1. 5G & RF Communications

SAW/BAW filters: Enable high-frequency (2-10 GHz), low-loss signal processing in smartphones and base stations.

FBAR resonators: Deliver high Q-factor (>1000) for RF oscillators.

2. Optics & Infrared Technologies

IR detector windows: Leverage broadband transparency for thermal imaging and military reconnaissance.

Electro-optic modulators: Facilitate high-speed optical signal modulation in fiber optics.

3. Automotive & Industrial Sensing

Ultrasonic sensors: For parking assistance and TPMS, withstanding engine compartment temperatures.

High-temperature pressure sensors: Reliable performance in oil exploration and industrial controls.

4. Defense & Aerospace

EW filters: Radiation-hardened for military radar/communication systems.

Missile seeker components: Thermal stability ensures reliability in extreme conditions.

5. Consumer Electronics

RF frontend modules: Enhance signal selectivity in smartphones.

Smart home sensors: Ultrasonic ranging and gesture recognition.

Key Advantages of LiTaO₃ Ingots

1. Exceptional Crystal Quality and Consistency

LiTaO₃ Ingots are manufactured using high-purity Ta₂O₅ (≥99.999%) and optimized Czochralski (CZ) method, achieving:

Ultra-low defect density (dislocations <500 cm⁻², inclusions ≤5/cm³)

Axial/radial resistivity variation <5% (ensuring batch-to-batch consistency)

X/Y/Z-cut orientation accuracy ±0.5° (meeting SAW device phase coherence requirements)

2. Superior Piezoelectric and Thermal Performanc

High piezoelectric coefficient (d₃₃~8 pC/N), 30% higher than LiNbO₃, ideal for high-frequency BAW filter design

Curie temperature 600°C (operating range -50~300°C), maintaining in extreme environments:

Frequency temperature coefficient (TCF) <|-15ppm/°C|

Electromechanical coupling coefficient (K²) variation <0.5%

3. Customization and Integration Flexibility

Adjustable doping (MgO 0-8mol%):

5mol% MgO doping increases laser damage threshold by 10x

Zn doping optimizes microwave dielectric loss (tanδ<0.001 @10GHz)

Heterogeneous integration: Supports LNOI (LiTaO₃-on-Insulator) thin-film preparation and bonding with Si/SiN photonic chips

4. Scalable Supply Assurance

6-inch (150mm) mass production technology: 40% cost reduction compared to 4-inch

Rapid delivery: Standard orientations available from stock (3-week lead time), supports small-batch customization from 5kg (4-week cycle)

LiTaO₃ Ingot - XKH Services

1. Cost Efficiency: 8-inch ingots reduce material waste by 30% compared to 4-inch alternatives, lowering per-unit costs by 18% .

2. Performance Metrics:

SAW Filter Bandwidth: >1.28 GHz (vs. 0.8 GHz for LiTaO3), critical for 5G mmWave bands .

Thermal Cycling: Survives -200–500°C cycles with <0.05% warpage, validated in automotive LiDAR testing .

1. Sustainability: Recyclable processing methods reduce water consumption by 40% and energy use by 25%.

Conclusion

LiTaO₃ ingots continue to drive innovation in 5G communications, photonics, and defense systems through their unique piezoelectric properties and environmental resilience. Our material expertise, scalable production, and application engineering support position us as the preferred partner for advanced electronic systems.