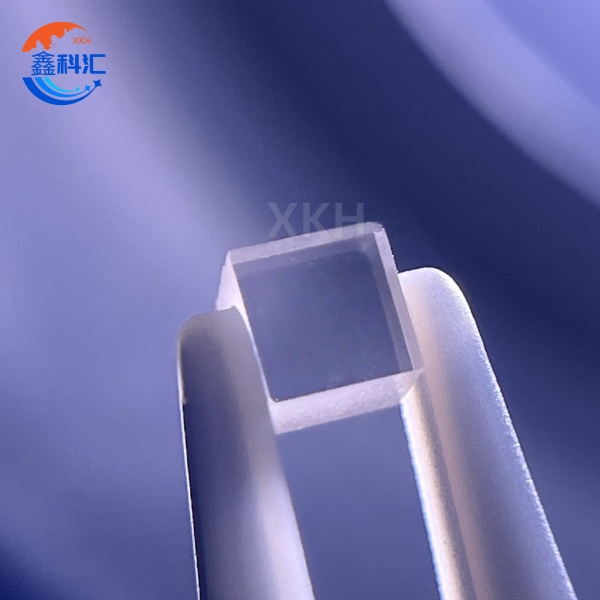

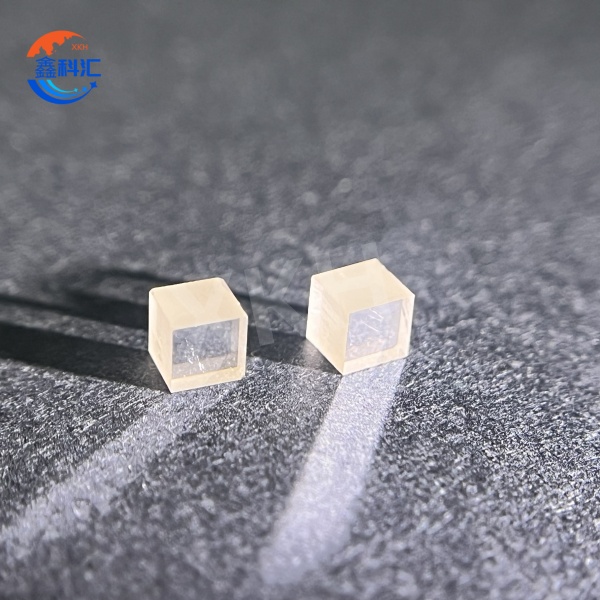

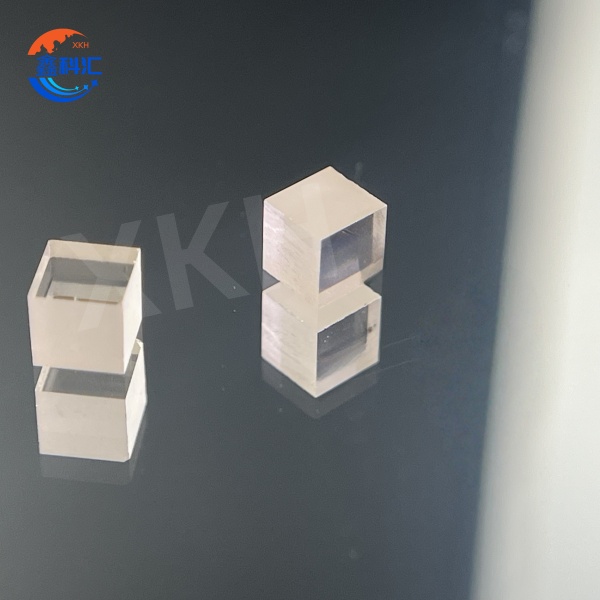

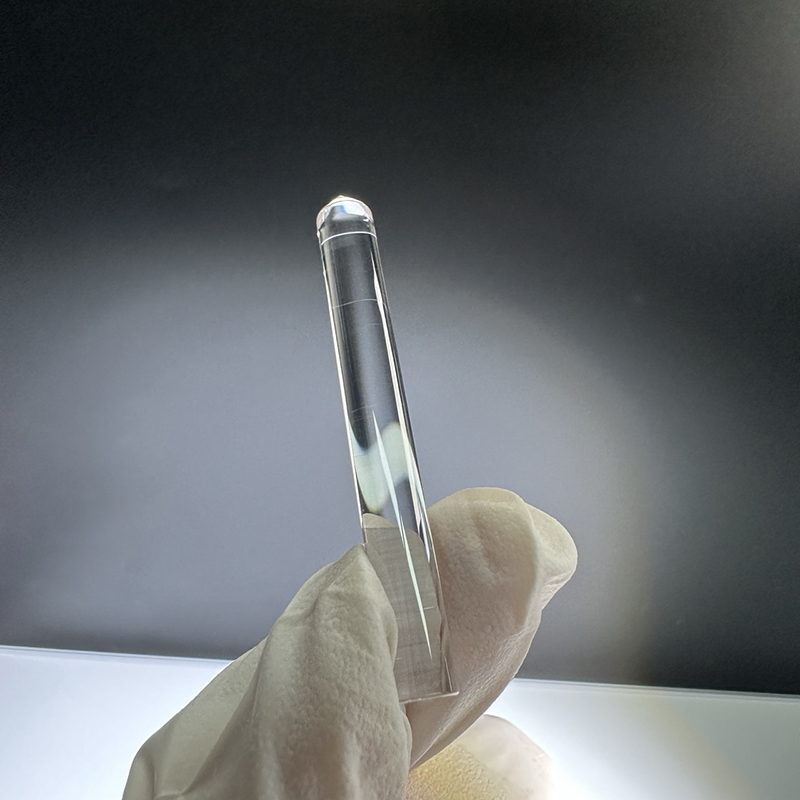

High Purity SiC Optical Lens Cubic 4H-semi 6SP Size Customized

Characteristics of SiC Optical Lens

1. Material Superiority

Extreme Environment Adaptability: Withstands temperatures >1500°C, strong acid/alkali corrosion, and high-energy radiation, ideal for spacecraft and nuclear facilities.

Exceptional Mechanical Strength: Near-diamond hardness (Mohs 9.5), flexural strength >400 MPa, and impact resistance far exceeding conventional optical glass.

Thermal Stability: Thermal conductivity 100× higher than fused silica, with CTE just 1/10 of ordinary glass, ensuring stability under rapid thermal cycling.

2. Optical Performance Advantages

Broad spectral transmission (0.2-6 μm); specialized coatings can optimize transmittance to >95% in specific bands (e.g., 3-5 μm mid-IR).

Low scattering loss (<0.5%/cm), surface finish up to 10/5 scratch-dig standard, and surface flatness λ/10@633 nm.

High laser-induced damage threshold (LIDT) >15 J/cm² (1064 nm, 10 ns pulses), suitable for high-power laser focusing systems.

3. Precision Machining Capabilities

Supports complex surfaces (aspheric, freeform) with form accuracy <100 nm PV and centration <1 arcmin.

Capable of fabricating oversized SiC lenses (diameter >500 mm) for astronomical telescopes and space optics.

Primary Applications of SiC Optical Lens

1. Space Optics & Defense

Satellite remote sensing lenses and space telescope optics, leveraging SiC's lightweight properties (density 3.21 g/cm³) and radiation resistance.

Missile seeker optical windows, enduring aerodynamic heating (>1000°C) during hypersonic flight.

2. High-Power Laser Systems

Focus lenses for industrial laser cutting/welding equipment, sustaining prolonged exposure to kW-class continuous lasers.

Beam shaping elements in inertial confinement fusion (ICF) systems, ensuring precise high-energy laser transmission.

3. Semiconductor & Precision Manufacturing

SiC mirror substrates for EUV lithography optics, with thermal deformation <1 nm under 10 kW/m² heat flux.

Electromagnetic lenses for e-beam inspection tools, utilizing SiC's conductivity for active temperature control.

4. Industrial Inspection & Energy

Endoscope lenses for high-temperature furnaces (1500°C continuous operation).

Infrared optical components for oil well logging instruments, resisting downhole pressures (>100 MPa) and corrosive media.

Core Competitive Advantages

1. Comprehensive Performance Leadership

SiC lenses surpass traditional optical materials (fused silica, ZnSe) in thermal/mechanical/chemical stability, with their "high conductivity + low expansion" properties solving thermal deformation challenges in large optics.

2. Lifecycle Cost Efficiency

While initial costs are higher, SiC lenses' extended service life (5-10× conventional glass) and maintenance-free operation significantly reduce total cost of ownership (TCO).

3. Design Freedom

Reaction-bonded or CVD processes enable lightweight SiC optical structures (honeycomb cores), achieving unmatched stiffness-to-weight ratios.

XKH Service Capabilities

1. Custom Manufacturing Services

End-to-end solutions from optical design (Zemax/Code V simulation) to final delivery, supporting aspheric/off-axis parabolic freeform surfaces.

Specialized coatings: anti-reflection (AR), diamond-like carbon (LIDT>50 J/cm²), conductive ITO, etc.

2. Quality Assurance Systems

Metrology equipment including 4D interferometers and white-light profilers ensuring λ/20 surface accuracy.

Material-level QC: XRD crystallographic orientation analysis for every SiC blank.

3. Value-Added Services

Thermo-structural coupling analysis (ANSYS simulation) for performance prediction.

Integrated SiC lens mounting structure optimization design.

Conclusion

SiC lenses are redefining the performance limits of high-precision optical systems through their unparalleled material properties. Our vertically integrated capabilities in SiC material synthesis, precision machining, and testing deliver revolutionary optical solutions for aerospace and advanced manufacturing sectors. With advancements in SiC crystal growth, future developments will focus on larger apertures (>1m) and more complex surface geometries (freeform arrays).

As a leading manufacturer of advanced optical components,XKH specialize in high-performance materials including sapphire, silicon carbide (SiC), and silicon wafers, offering end-to-end solutions from raw material processing to precision finishing. Our expertise spans:

1. Custom Fabrication: Precision machining of complex geometries (aspheric, freeform) with tolerances to ±0.001mm

2. Material Versatility: Processing sapphire (UV-IR windows), SiC (high-power optics), and silicon (IR/micro-optics)

3. Value-Added Services:

Anti-reflective/durable coatings (UV-FIR)

Metrology-backed quality assurance (λ/20 flatness)

Cleanroom assembly for contamination-sensitive applications

Serving aerospace, semiconductor, and laser industries, we combine material science expertise with advanced manufacturing to deliver optics that withstand extreme environments while optimizing optical performance.