High-Purity Fused Quartz Ingot for Advanced Industrial

Detailed Diagram

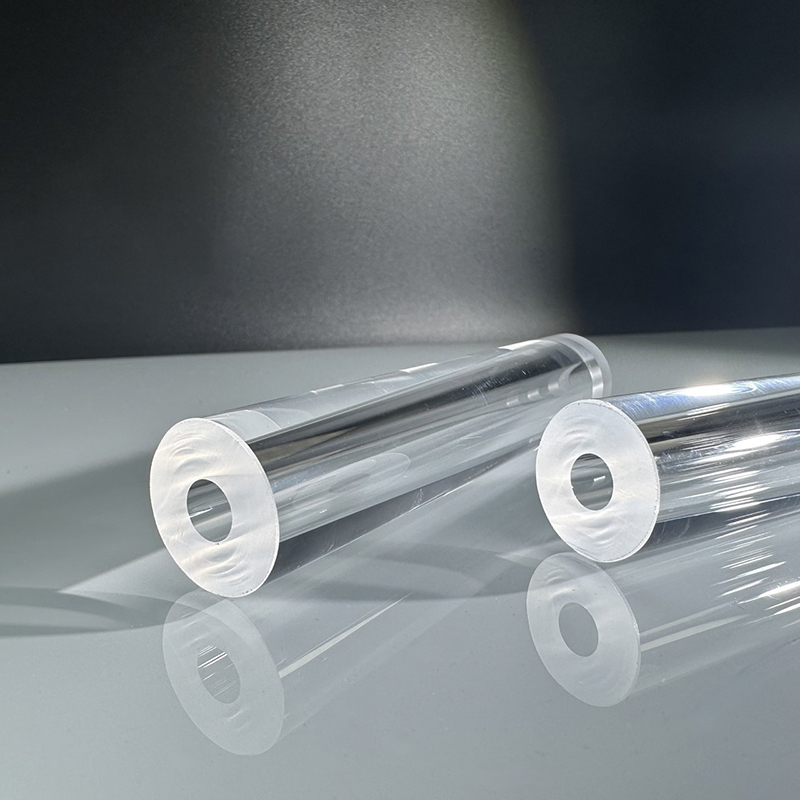

Product Description of Quartz ingots

Fused Quartz Ingots are solid blocks of ultra-high-purity silicon dioxide (SiO₂), manufactured through precise high-temperature fusion processes. As the fundamental raw material in the quartz industry, fused quartz ingots provide the structural and performance foundation for a wide range of downstream quartz products, including tubes, rods, plates, wafers, capillaries, optical elements, and semiconductor quartz components.

Thanks to their exceptional purity, structural uniformity, thermal stability, and optical transparency, fused quartz ingots are widely used in semiconductor fabrication, optical engineering, photovoltaic manufacturing, and other high-end industrial applications where material reliability is critical.

Material Characteristics of Quartz ingots

Fused quartz ingots are produced from carefully selected high-purity quartz sand or synthetic SiO₂ feedstock. The melting and solidification process is tightly controlled to achieve a dense, homogeneous structure with minimal bubbles and striae.

Key material characteristics include:

-

Extremely low metallic impurity levels

-

Uniform internal structure suitable for precision machining

-

Excellent resistance to thermal shock

-

Stable performance under harsh chemical environments

These properties make fused quartz ingots an ideal starting material for precision quartz components.

Performance Advantages of Quartz ingots

-

Ultra-High SiO₂ Content

Typical SiO₂ purity reaches 99.99% or higher, meeting the requirements of optical-grade and semiconductor-grade applications. -

Outstanding Thermal Properties

High softening point and ultra-low thermal expansion enable reliable use in high-temperature and rapid thermal cycling environments. -

Chemical Inertness

Resistant to most acids, alkalis, and corrosive gases, ensuring long service life in chemical and laboratory systems. -

Excellent Optical Behavior

High transmittance across UV, visible, and infrared wavelengths, suitable for optical windows and laser-related components. -

Process Compatibility

Easily processed through cutting, drilling, CNC machining, grinding, and polishing to meet complex design requirements.

Typical Quartz Products Derived from Ingots of Quartz

Fused quartz ingots can be further processed into various high-performance quartz products, including:

-

Quartz tubes for diffusion furnaces and chemical reactors

-

Quartz rods and bars for optical and mechanical components

-

Quartz plates and sheets for viewports and transparent structures

-

Quartz wafers for MEMS and sensor substrates

-

Quartz capillary tubes for analytical and medical devices

-

Optical quartz components such as lenses, windows, and prisms

-

Semiconductor quartz parts including boats, rings, and supports

-

Custom-shaped quartz components based on drawings or samples

FAQ of Quartz Glasses

Q1: What is the difference between fused quartz and fused silica?

A: Fused quartz is produced from natural quartz crystal melted at high temperature, while fused silica is synthesized from high-purity silicon compounds through chemical vapor deposition or hydrolysis. Fused silica typically has higher purity, better UV transmission, and lower impurity content than fused quartz.

Q2: Can quartz glass sheets withstand high temperatures?

A: Yes. Quartz glass sheets have excellent thermal stability and can operate continuously at temperatures up to 1100°C, with short-term resistance up to 1300°C. They also have extremely low thermal expansion, making them highly resistant to thermal shock.

Q3: Are quartz glass sheets resistant to chemicals?

A: Quartz is highly resistant to most acids, including hydrochloric, nitric, and sulfuric acids, as well as organic solvents. However, it can be attacked by hydrofluoric acid and strong alkaline solutions like sodium hydroxide.

Q4: Can I cut or drill quartz glass sheets myself?

A: We do not recommend DIY machining. Quartz is brittle and hard, requiring diamond tools and professional CNC or laser equipment for cutting or drilling. Improper handling may cause cracking or surface defects.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.