Fused Quartz Tubes

Detailed Diagram

Overview of Quartz Tube

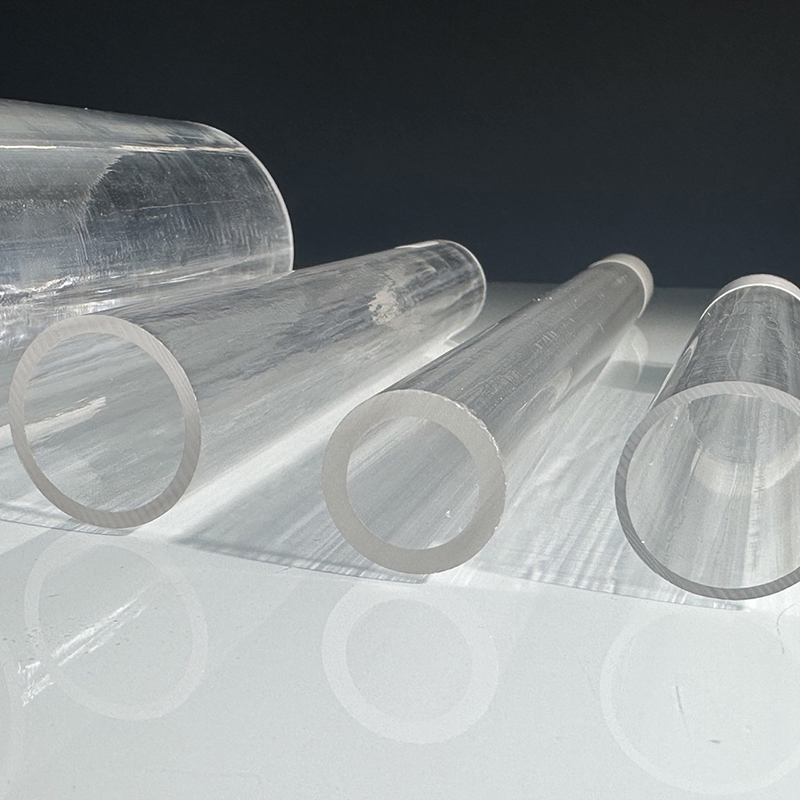

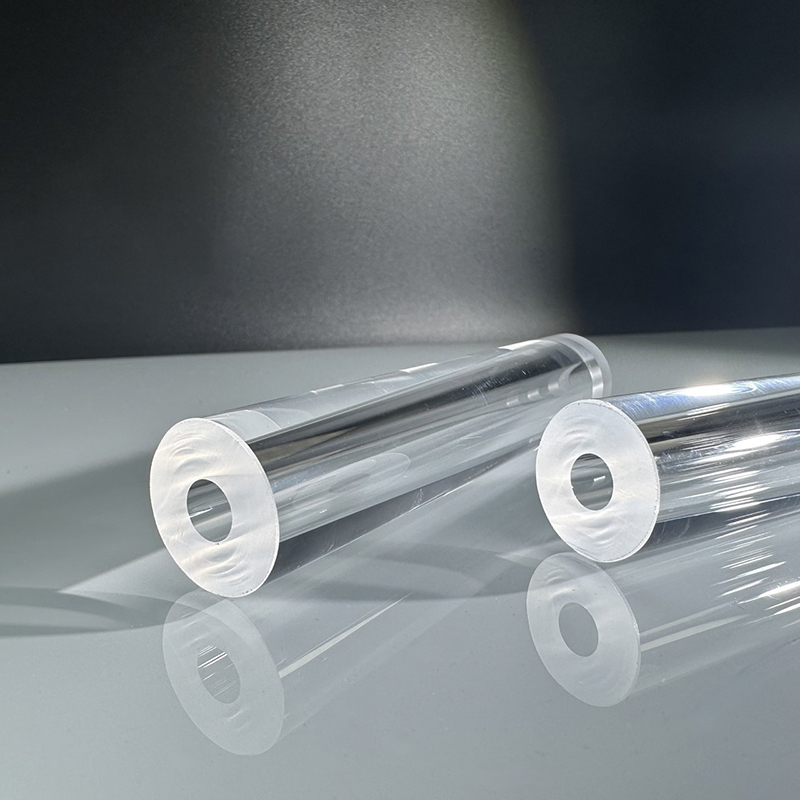

Fused quartz tubes are high-purity silica glass tubes manufactured through the melting of natural or synthetic crystalline silica. They are renowned for their exceptional thermal stability, chemical resistance, and optical clarity. Due to their unique properties, fused quartz tubes are widely used across semiconductor processing, laboratory equipment, lighting, and other high-tech industries.

Our fused quartz tubes are available in a wide range of diameters (1 mm to 400 mm), wall thicknesses, and lengths. We offer both transparent and translucent grades, as well as customized specifications to meet specific application requirements.

Key Features of Quartz Tube

-

High Purity: Typically >99.99% SiO₂ content ensures minimal contamination in high-tech processes.

-

Thermal Stability: Can withstand continuous working temperatures up to 1100°C and short-term temperatures up to 1300°C.

-

Excellent Optical Transmission: Superior transparency from UV to IR (based on grade), suitable for photonics and lamp industries.

-

Low Thermal Expansion: With a coefficient of thermal expansion as low as 5.5 × 10⁻⁷/°C, thermal shock resistance is excellent.

-

Chemical Durability: Resistant to most acids and corrosive environments, ideal for laboratory and industrial use.

-

Customizable Dimensions: Tailor-made lengths, diameters, end finishes, and surface polishing available on request.

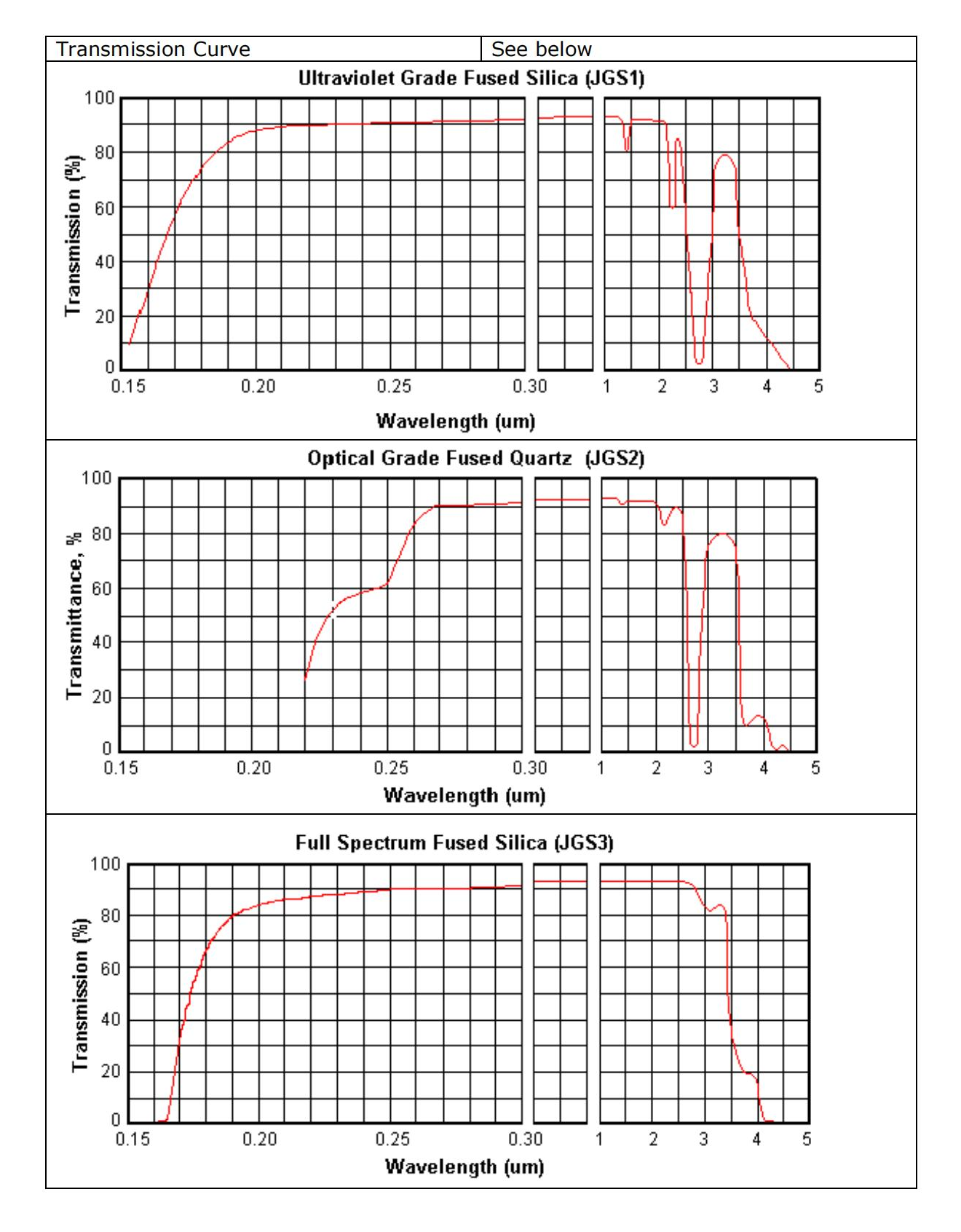

JGS Grade Classification

Quartz glass is often categorized by JGS1, JGS2, and JGS3 grades, commonly used in domestic and export markets:

JGS1 – UV Optical Grade Fused Silica

-

High UV transmittance (down to 185 nm)

-

Synthetic material, low impurity

-

Used in deep UV applications, UV lasers, and precision optics

JGS2 – Infrared and Visible Grade Quartz

-

Good IR and visible transmission, poor UV transmission below 260 nm

-

Lower cost than JGS1

-

Ideal for IR windows, viewing ports, and non-UV optical devices

JGS3 – General Industrial Quartz Glass

-

Includes both fused quartz and basic fused silica

-

Used in general high-temperature or chemical applications

-

Cost-effective option for non-optical needs

Mechanical Properties of Quartz Tube

| Quartz Characteristic | |

| SIO2 | 99.9% |

| Density | 2.2(g/cm³) |

| Degree of hardness moh’ scale | 6.6 |

| Melting point | 1732℃ |

| Working temperature | 1100℃ |

| Max temperature can reach in a short time | 1450℃ |

| Visible light transmittance | Above 93% |

| UV spectral region transmittance | 80% |

| Annealing point | 1180℃ |

| Softening point | 1630℃ |

| Strain point | 1100℃ |

Applications of Quartz Tube

-

Semiconductor Industry: Used as process tubes in diffusion and CVD furnaces.

-

Laboratory & Analytical Equipment: Ideal for sample containment, gas flow systems, and reactors.

-

Lighting Industry: Employed in halogen lamps, UV lamps, and high-intensity discharge lamps.

-

Solar & Photovoltaics: Applied in silicon ingot production and quartz crucible processing.

-

Optical & Laser Systems: As protective tubes or optical components in UV and IR ranges.

-

Chemical Processing: For corrosive fluid transport or reaction containment.

FAQ of Quartz Glasses

Frequently Asked Questions (FAQ)

Q1: What is the difference between fused quartz and fused silica?

A: Both refer to non-crystalline (amorphous) silica glass, but "fused quartz" typically comes from natural quartz, while "fused silica" is derived from synthetic sources. Fused silica generally has higher purity and better UV transmission.

Q2: Are these tubes suitable for vacuum applications?

A: Yes, due to their low permeability and high structural integrity at elevated temperatures.

Q3: Do you offer large-diameter tubes?

A: Yes, we supply large fused quartz tubes up to 400 mm outer diameter, depending on grade and length.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.