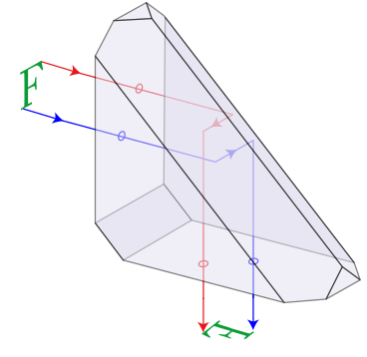

Fused Quartz Prism

Detailed Diagram

Overview of Quartz Prisms

Fused quartz prisms are essential optical elements used to control, manipulate, and redirect light in a wide range of high-performance optical systems. Manufactured from ultra-high purity fused silica, these prisms offer exceptional transmission properties across the ultraviolet (UV), visible, and near-infrared (NIR) spectral ranges. With outstanding thermal and chemical resistance, excellent mechanical strength, and minimal birefringence, fused quartz prisms are ideal for critical applications in spectroscopy, laser optics, imaging, and scientific instrumentation.

Fused quartz is a non-crystalline, amorphous form of silicon dioxide (SiO₂) that exhibits extremely low impurity levels and superior optical homogeneity. These features enable fused quartz prisms to perform with minimal distortion, even under extreme environmental conditions.

Material Properties of of Quartz Prisms

Fused quartz is selected for optical prism fabrication due to its unique set of properties:

-

High Optical Transmission: Superior light transmittance from deep ultraviolet (185 nm) through visible to near-infrared (up to ~2500 nm), making it suitable for both UV and IR applications.

-

Excellent Thermal Stability: Maintains optical and mechanical integrity up to temperatures exceeding 1000°C. Ideal for high-temperature optical systems.

-

Low Coefficient of Thermal Expansion: Only ~0.55 × 10⁻⁶ /°C, resulting in excellent dimensional stability under thermal cycling.

-

Exceptional Purity: Typically greater than 99.99% SiO₂, reducing the risk of signal contamination in precision systems.

-

High Resistance to Chemicals and Corrosion: Withstands most acids and solvents, making it suitable for harsh chemical environments.

-

Low Birefringence: Ideal for polarization-sensitive systems due to minimal internal strain.

Types of Quartz Prisms

1. Right-Angle Prism

-

Structure: A triangular prism with one 90° angle and two 45° angles.

-

Function: Redirects light by 90° or 180° depending on orientation and usage.

-

Applications: Beam steering, image rotation, periscopes, alignment tools.

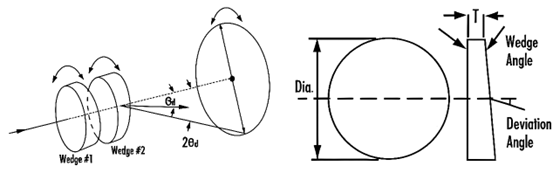

2. Wedge Prism

-

Structure: Two flat surfaces angled slightly from one another (like a thin slice of pie).

-

Function: Deviates light by a small, precise angle; can be rotated to scan the beam circularly.

-

Applications: Laser beam steering, adaptive optics, ophthalmology instruments.

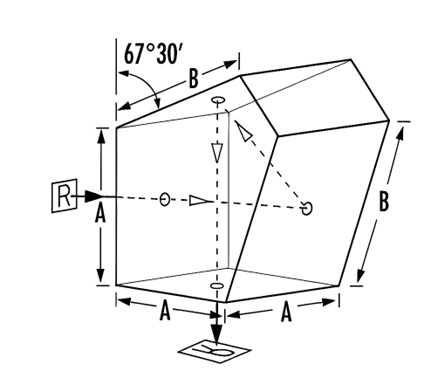

3. Pentaprism

-

Structure: Five-sided prism with two reflective surfaces.

-

Function: Deflects light by exactly 90° regardless of entry angle; maintains image orientation.

-

Applications: DSLR viewfinders, surveying equipment, alignment optics.

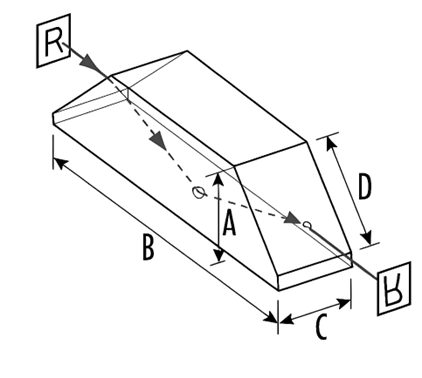

4. Dove Prism

-

Structure: A long, narrow prism with a trapezoidal profile.

-

Function: Rotates an image by twice the angle of the prism’s physical rotation.

-

Applications: Image rotation in beam delivery systems, interferometers.

5. Roof Prism (Amici Prism)

-

Structure: A right-angle prism with a “roof” edge forming a 90° V-shape.

-

Function: Inverts and reverts the image, maintaining correct orientation in binoculars.

-

Applications: Binoculars, spotting scopes, compact optical systems.

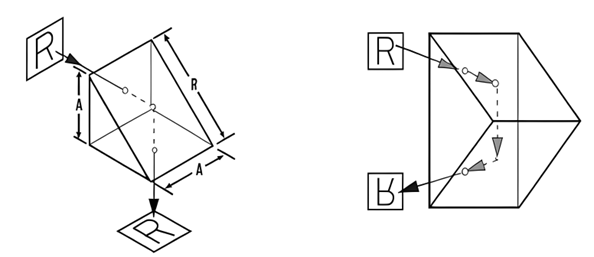

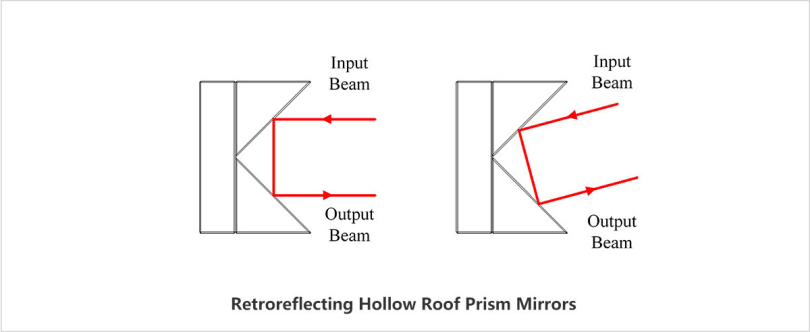

7. Hollow Roof Mirror Prism

-

Structure: Two right-angle prisms arranged to form a fixed-angle reflective pair.

-

Function: Reflects beams parallel to incident direction but with lateral shift, avoiding interference.

-

Applications: Beam folding in laser systems, optical delay lines, interferometers.

Applications of Fused Quartz Prisms

Due to their versatility, fused quartz prisms are used in a variety of high-end optical systems:

-

Spectroscopy: Equilateral and dispersive prisms are used for light dispersion and wavelength separation in spectrometers and monochromators.

-

Laser Systems: Prisms are employed in laser beam steering, combining, or splitting applications, where high laser damage threshold is critical.

-

Optical Imaging and Microscopy: Right-angle and Dove prisms assist in image rotation, beam alignment, and optical path folding.

-

Metrology and Precision Instruments: Penta prisms and roof prisms are integrated into alignment tools, distance measurement, and optical surveying systems.

-

UV Lithography: Due to their high UV transmittance, fused quartz prisms are used in photolithography exposure tools.

-

Astronomy and Telescopes: Used in beam deviation and orientation correction without affecting optical fidelity.

FAQs – Frequently Asked Questions of Quartz Prisms

Q1: What is the difference between fused quartz and fused silica?

A: While the terms are sometimes used interchangeably, "fused quartz" generally refers to silica glass made from natural quartz crystals, whereas "fused silica" is made from synthetic silica gas. Both offer similar optical performance, but fused silica may have slightly better UV transmission.

Q2: Can you apply anti-reflective coatings on fused quartz prisms?

A: Yes, we offer custom AR coatings designed for specific wavelength ranges, including UV, visible, and NIR. Coatings improve transmission and reduce reflection losses at prism surfaces.

Q3: What surface quality can you provide?

A: Standard surface quality is 40-20 (scratch-dig), but we also offer higher precision polishing to 20-10 or better, depending on application.

Q4: Are quartz prisms suitable for UV laser applications?

A: Absolutely. Due to their high UV transparency and laser damage threshold, fused quartz prisms are ideal for UV lasers, including excimer and solid-state sources.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.