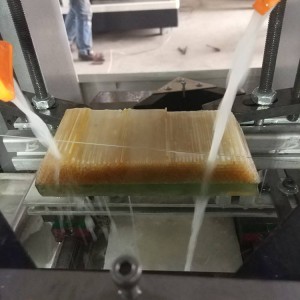

Diamond Wire Three-Station Single-Wire Cutting Machine for Si Wafer/Optical Glass Material Cutting

Product Introduction

The diamond wire three-station single-wire cutting machine is a high-precision and high-efficiency cutting equipment designed for hard and brittle materials. It utilizes diamond wire as the cutting medium and is suitable for precision processing of high-hardness materials such as silicon wafers, sapphire, silicon carbide (SiC), ceramics, and optical glass. Featuring a three-station design, this machine enables simultaneous cutting of multiple workpieces on a single device, significantly improving production efficiency and reducing manufacturing costs.

Working Principle

- Diamond Wire Cutting: Uses electroplated or resin-bonded diamond wire to perform grinding-based cutting through high-speed reciprocating motion.

- Three-Station Synchronous Cutting: Equipped with three independent workstations, allowing simultaneous cutting of three pieces to enhance throughput.

- Tension Control: Incorporates a high-precision tension control system to maintain stable diamond wire tension during cutting, ensuring accuracy.

- Cooling & Lubrication System: Employs deionized water or specialized coolant to minimize thermal damage and extend diamond wire lifespan.

Equipment Features

- High-Precision Cutting: Achieves cutting accuracy of ±0.02mm, ideal for ultra-thin wafer processing (e.g., photovoltaic silicon wafers, semiconductor wafers).

- High Efficiency: The three-station design increases productivity by over 200% compared to single-station machines.

- Low Material Loss: Narrow kerf design (0.1–0.2mm) reduces material waste.

- High Automation: Features automatic loading, alignment, cutting, and unloading systems, minimizing manual intervention.

- High Adaptability: Capable of cutting various hard and brittle materials, including monocrystalline silicon, polycrystalline silicon, sapphire, SiC, and ceramics.

Technical Advantages

|

Advantage

|

Description

|

|

Multi-Station Synchronous Cutting

|

Three independently controlled stations enable cutting of workpieces with different thicknesses or materials, improving equipment utilization.

|

|

Intelligent Tension Control

|

Closed-loop control with servo motors and sensors ensures constant wire tension, preventing breakage or cutting deviations.

|

|

High-Rigidity Structure

|

High-precision linear guides and servo-driven systems ensure stable cutting and minimize vibration effects.

|

|

Energy Efficiency & Eco-Friendliness

|

Compared to traditional slurry cutting, diamond wire cutting is pollution-free, and coolant can be recycled, reducing waste treatment costs.

|

|

Intelligent Monitoring

|

Equipped with PLC and touch-screen control systems for real-time monitoring of cutting speed, tension, temperature, and other parameters, supporting data traceability. |

Technical Specification

| Model | Three station diamond single line cutting machine |

| Maximum workpiece size | 600*600mm |

| Wire running speed | 1000 (MIX) m/min |

| Diamond wire diameter | 0.25-0.48mm |

| Line storage capacity of supply wheel | 20km |

| Cutting thickness range | 0-600mm |

| Cutting accuracy | 0.01mm |

| Vertical lifting stroke of workstation | 800mm |

| Cutting method | The material is stationary, and the diamond wire sways and descends |

| Cutting feed speed | 0.01-10mm/min (According to the material and thickness) |

| Water tank | 150L |

| Cutting fluid | Anti rust high-efficiency cutting fluid |

| Swing angle | ±10° |

| Swing speed | 25°/s |

| Maximum cutting tension | 88.0N (Set minimum unit0.1n) |

| Cutting depth | 200~600mm |

| Make corresponding connecting plates according to the customer's cutting range | - |

| Workstation | 3 |

| Power supply | Three phase five wire AC380V/50Hz |

| Total power of machine tool | ≤32kw |

| Main motor | 1*2kw |

| Wiring motor | 1*2kw |

| Workbench swing motor | 0.4*6kw |

| Tension control motor | 4.4*2kw |

| Wire release and collection motor | 5.5*2kw |

| External dimensions (excluding rocker arm box) | 4859*2190*2184mm |

| External dimensions (including rocker arm box) | 4859*2190*2184mm |

| Machine weight | 3600ka |

Application Fields

- Photovoltaic Industry: Slicing of monocrystalline and polycrystalline silicon ingots to improve wafer yield.

- Semiconductor Industry: Precision cutting of SiC and GaN wafers.

- LED Industry: Cutting sapphire substrates for LED chip manufacturing.

- Advanced Ceramics: Forming and cutting high-performance ceramics like alumina and silicon nitride.

- Optical Glass: Precision processing of ultra-thin glass for camera lenses and infrared windows.