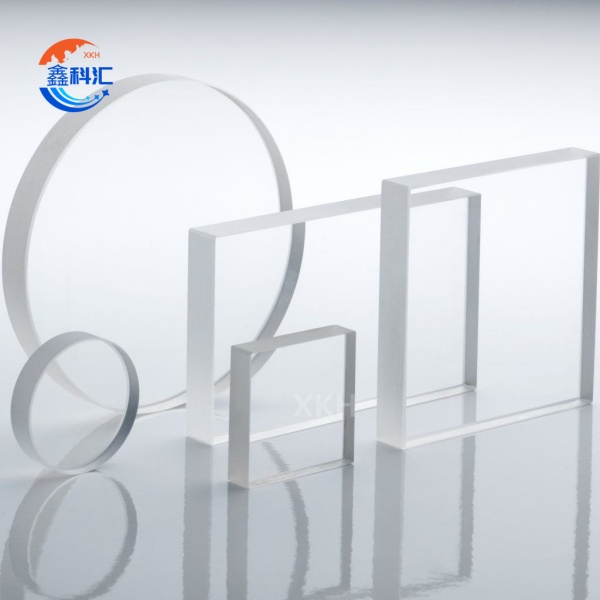

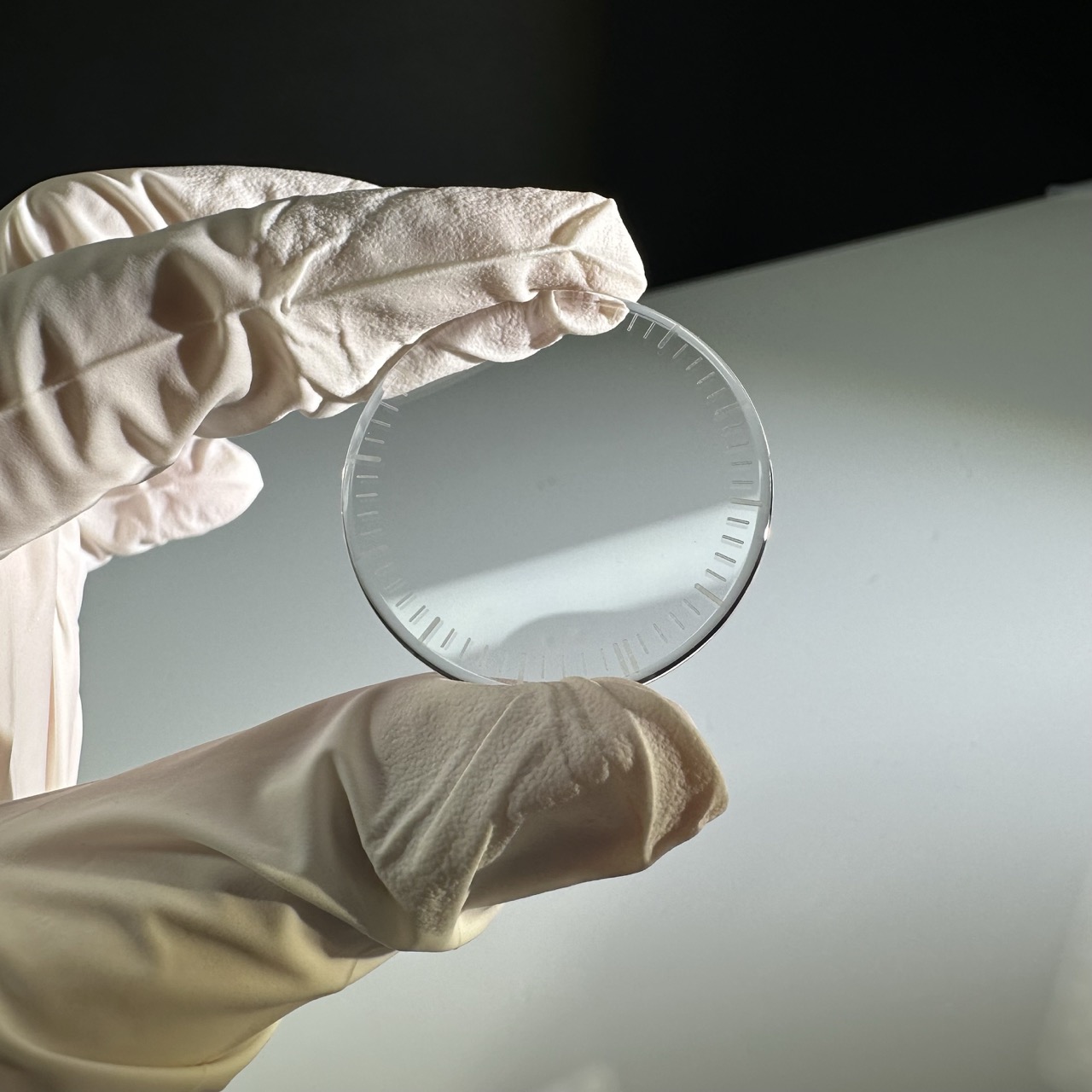

Customized Sapphire Glass Windows Sapphire Optical Parts

Technical specification

| Name | optical glass |

| Material | Sapphire,quartz |

| Diameter Tolerance | +/-0.03 mm |

| Thickness Tolerance | +/-0.01 mm |

| Cler Aperture | over 90% |

| Flatness | ^/4 @632.8nm |

| Surface Quality | 80/50~10/5 scratch and dig |

| Transmission | above 92% |

| Chamfer | 0.1-0.3 mm x 45 degree |

| Focal Length Tolerance | +/-2% |

| Back Focal Length Tolerance | +/-2% |

| Coating | available |

| Usage | opticl system, photographic sysem, Lighting system,Electronic apparatuse.g.laser,camera,monitor,projector,magnifier,telescope,polarizer,electronic instrument,led etc. |

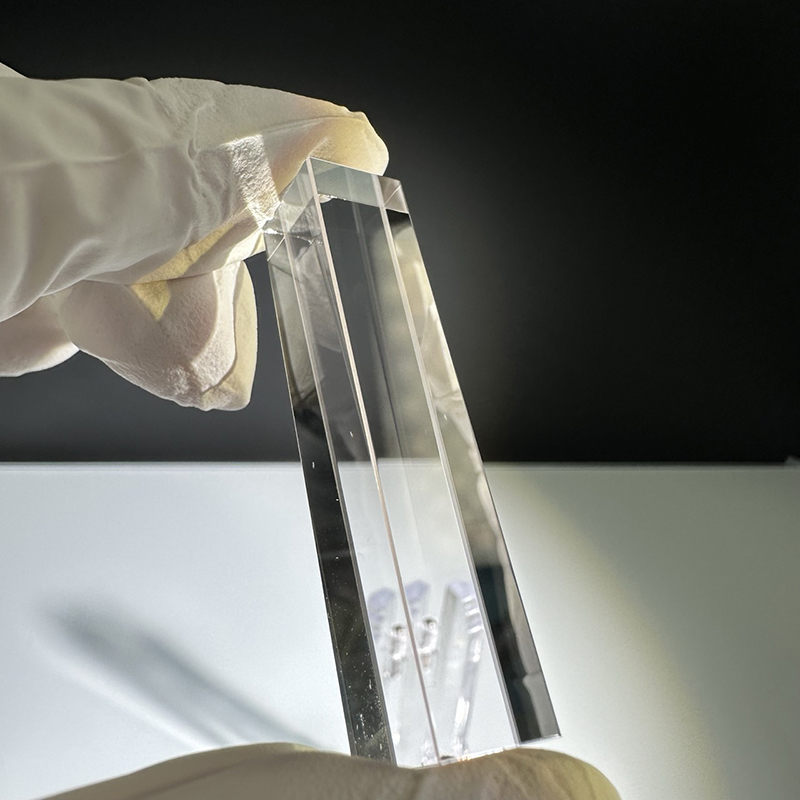

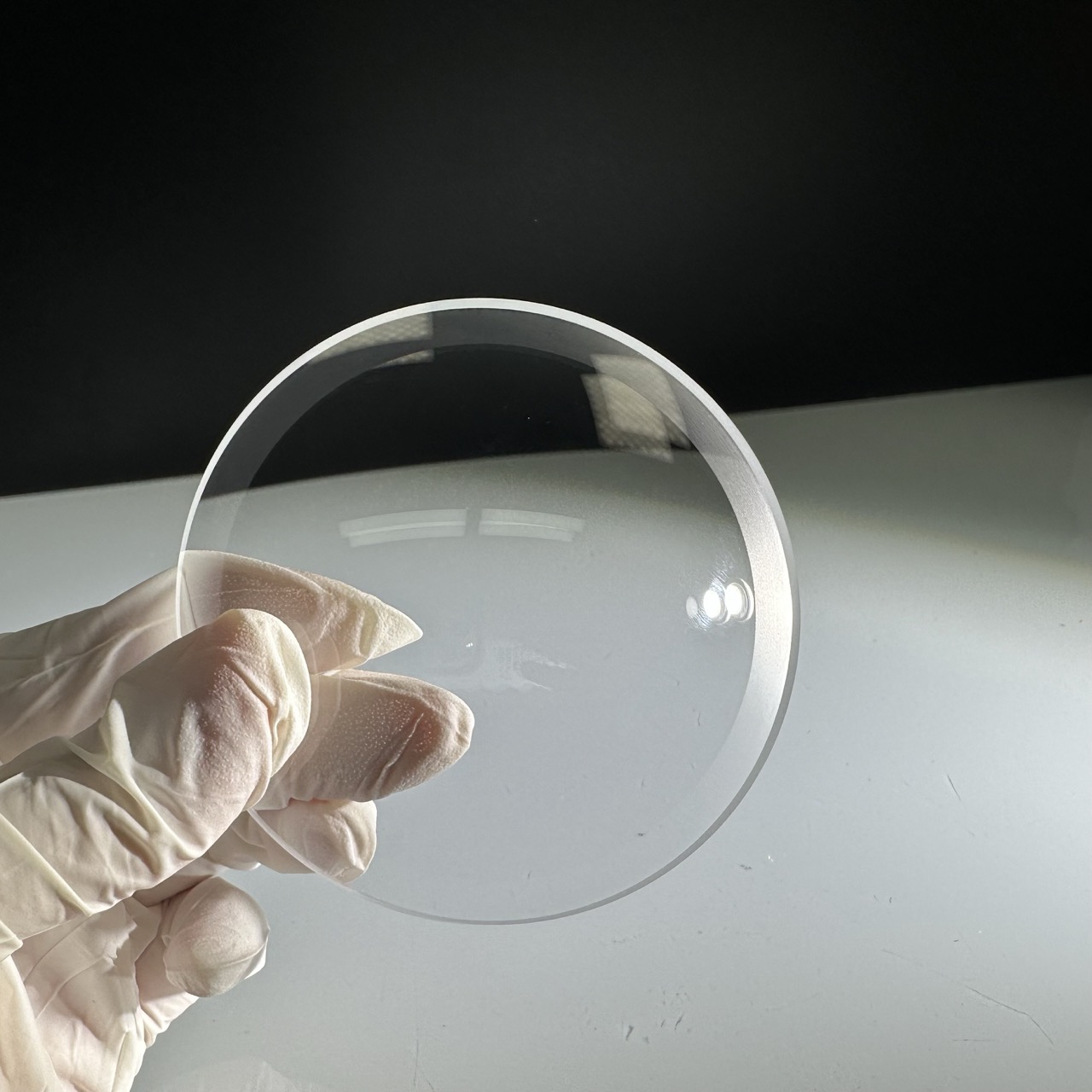

Material Excellence: The Foundation of Performance

Synthetic sapphire’s intrinsic properties set it apart as the material of choice for high-performance optics. With a Mohs hardness of 9—second only to diamond—these windows resist abrasion, scratches, and wear, even in abrasive industrial settings such as laser machining or robotic vision systems. Their thermal stability spans an astonishing range of -200°C to 2053°C, enabling applications in aerospace thermal protection systems and high-temperature industrial reactors. Chemical inertness further ensures compatibility with aggressive solvents, acids, and alkalis, critical for pharmaceutical and semiconductor manufacturing.

The optical transparency of sapphire spans 200nm (UV) to 6μm (mid-IR), achieving >85% transmittance across this spectrum. This broad range supports multi-spectral imaging in remote sensing, quantum communication systems, and advanced LiDAR sensors for autonomous vehicles. Unlike quartz or polymers, sapphire’s zero birefringence minimizes optical distortion, ensuring precision in interferometry and gravitational wave detection.

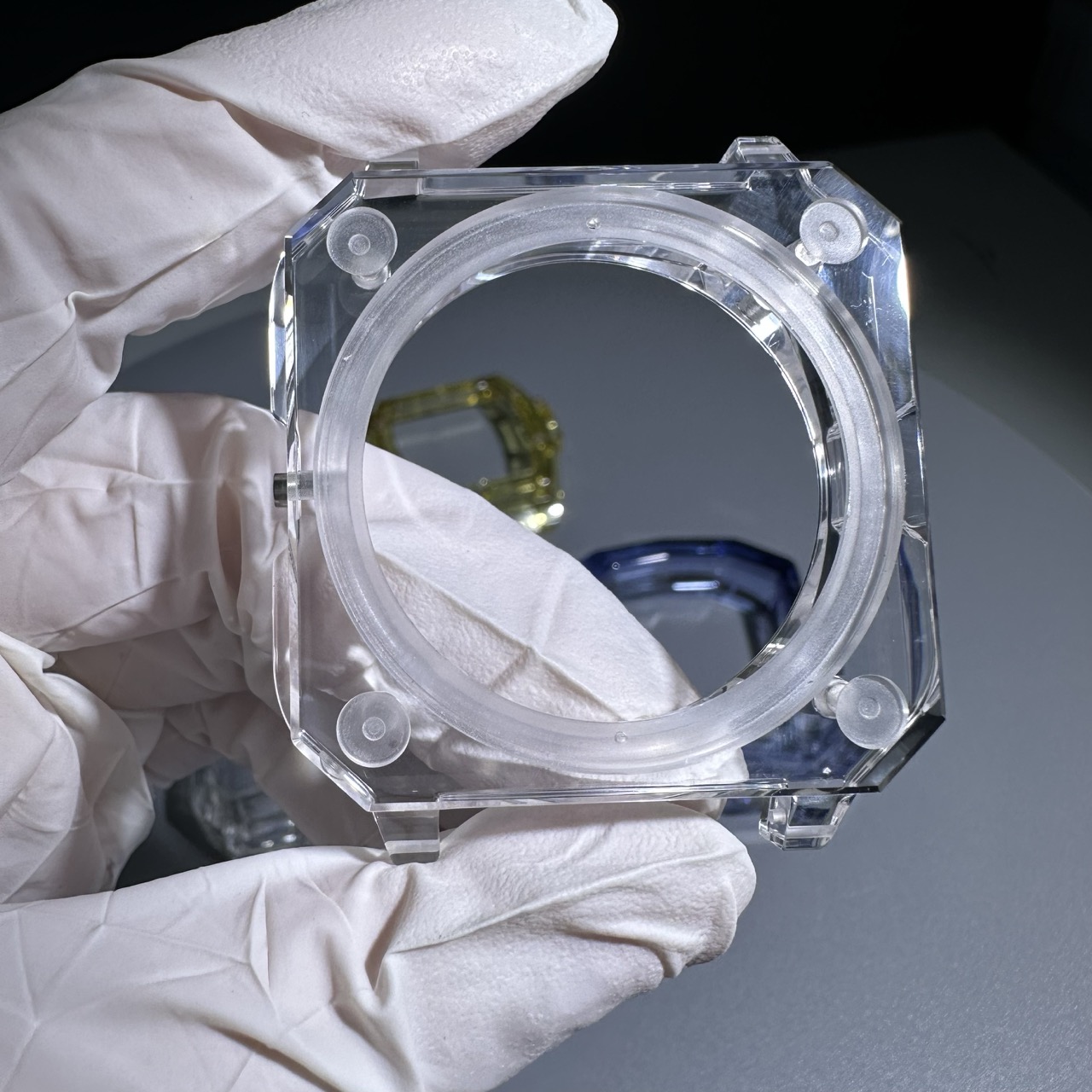

Advanced Design & Functional Integration

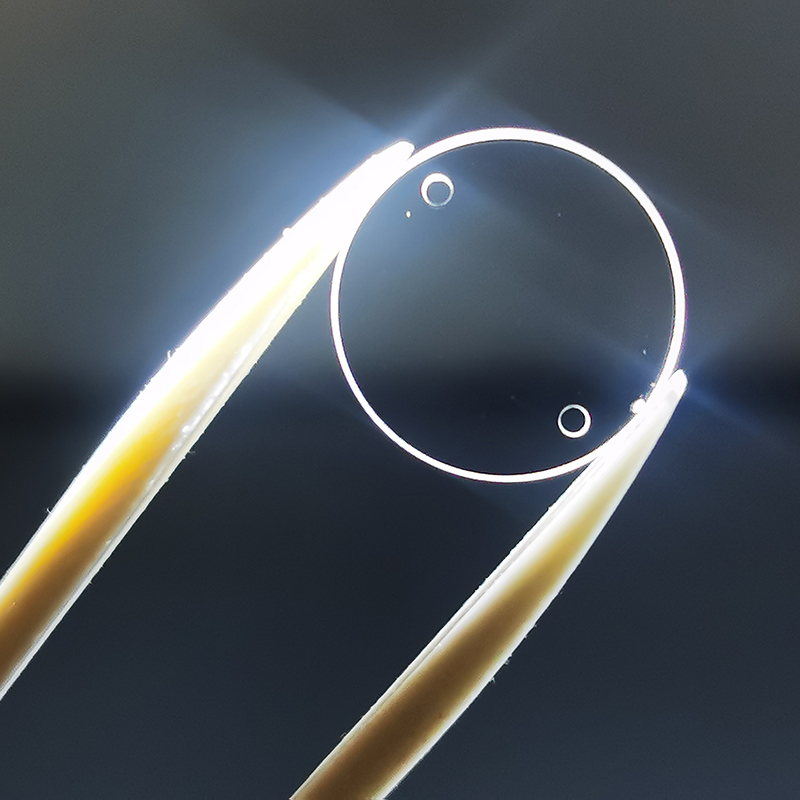

Modern sapphire windows are not mere static components—they are engineered for dynamic performance. Aspheric and free-form geometries eliminate spherical aberrations, enhancing resolution in high-powered laser systems and hyperspectral cameras. For instance, elliptical apertures optimize light-gathering efficiency in satellite imaging, while tapered designs enable seamless integration into confined spaces like medical endoscopes.

Functional coatings elevate their capabilities:

· Anti-Reflective Coatings (AR): Multi-layer dielectric coatings reduce reflectivity to <0.3%, boosting throughput in 400G optical modules and UV lithography systems.

· Bandpass Filters: Custom filters (e.g., 940nm IR) enable wavelength-selective transmission for LiDAR and quantum key distribution.

· Diamond-Like Carbon (DLC): Ultra-hard DLC coatings enhance scratch resistance for aerospace domes exposed to micrometeoroid impacts.

Applications Across Critical Industries

1.Aerospace & Defense

· Satellite Imaging: Survive -196°C to +120°C thermal cycling in Earth observation satellites, capturing high-resolution imagery for climate monitoring.

· Hypersonic Systems: Withstand 2000°C thermal shocks during atmospheric re-entry, protecting missile guidance systems.

2.Medical Technology

· Autoclave-Safe Endoscopes: Resist corrosion from sterilization processes, enabling reusable gastrointestinal diagnostic tools.

· Infrared Thermography: Detect sub-millimeter heat signatures in electrical equipment inspections with FLIR-compatible optics.

3.Industrial Automation

· LiDAR Sensors: Improve detection range to 200m+ in adverse weather (rain, fog) for autonomous vehicle navigation.

· High-Temperature Sensors: Monitor furnaces exceeding 1500°C in metallurgical processes, leveraging sapphire’s thermal shock resistance.

4.Quantum Innovations

· Single-Photon Detectors: Enable low-noise photon counting for secure quantum communication networks.

· Cryogenic Systems: Maintain optical clarity at 4K temperatures in quantum computing platforms.

Customization & Scalable Solutions

XKH's "Material-Process-Service" paradigm ensures tailored solutions:

1.Complex Geometries: Accept CAD models with ±0.001mm tolerances for non-standard shapes (e.g., spiral heat-dissipation windows for fusion reactors).

2.Multi-Layer Coatings: Ion-beam sputtering achieves 98% transmittance at 940nm, critical for facial recognition systems.

3.Mass Production: Automated fabrication yields 500,000+ units/month with 99.5% consistency, supporting rapid prototyping (7-day turnaround) and bulk orders.

Conclusion: Shaping Tomorrow’s Optical Frontier

Sapphire optical windows are more than components—they are enablers of technological breakthroughs. From hypersonic defense systems to next-gen quantum computers, their unmatched material properties and design flexibility empower industries to overcome extreme challenges. With rapid global deployment and a commitment to innovation, these windows redefine standards in optical engineering, driving progress in sustainability, miniaturization, and mission-critical reliability. Partner with us to harness the power of sapphire and unlock new frontiers in photonics.