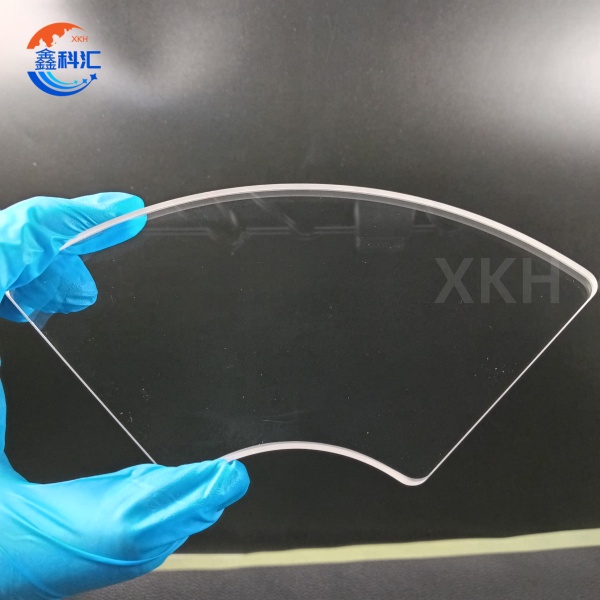

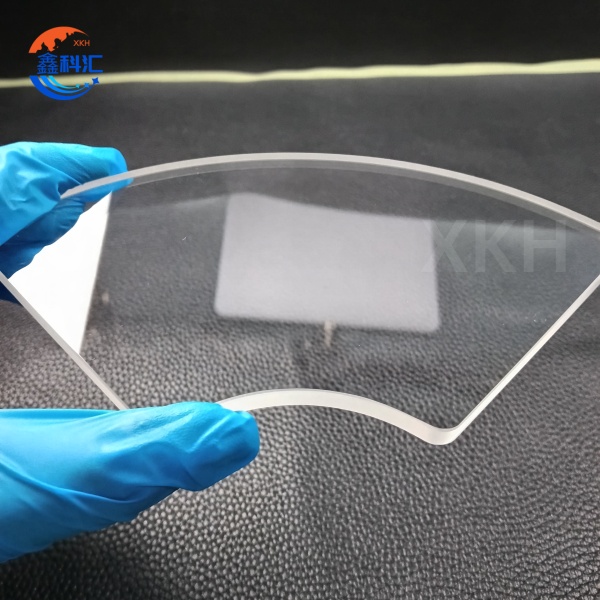

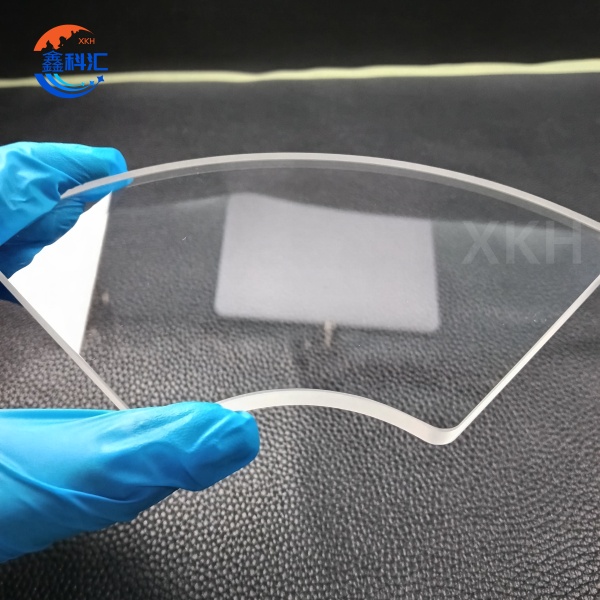

Custom-Shaped Sapphire Window High Hardness for Smartphone Screens

Technical parameters

Sapphire window |

|

Dimension |

8-400mm |

Dimensional tolerance |

+0/-0.05mm |

Surface quality(scratch&dig) |

40/20 |

Surface accuracy |

λ/10per@633nm |

Clear Aperture |

>85%,>90% |

Parallelism tolerance |

±2''-±3'' |

Bevel |

0.1-0.3mm |

Coating |

AR/AF/upon customer request |

Key Features of Custom-shaped Sapphire Windows

1. Exceptional Mechanical Performance:

Mohs hardness of 9, offering superior scratch resistance compared to glass.

Melting point of 2050°C, maintaining structural integrity up to 1900°C in extreme environments (e.g., furnace monitoring).

2. Superior Optical Properties:

Broad-spectrum transparency from ultraviolet (0.15μm) to mid-infrared (5.5μm), with light transmittance exceeding 85% in visible to near-infrared ranges.

Ultra-low thermal expansion coefficient (5.3×10⁻⁷/°C), ensuring thermal stability under high temperatures.

3. Chemical Resistance & Durability:

Resists strong acids, alkalis, and harsh chemicals, ideal for aggressive industrial settings.

3x higher wear resistance than glass, enhanced via nano-coating for extended longevity.

4. Design Flexibility:

Supports intricate shapes (e.g., curved surfaces, blind holes, micro-holes as small as 50μm) with machining precision ±0.01mm.

Applications of Custom-shaped Sapphire Windows

1. Consumer Electronics:

Smartphone sapphire screens (e.g., Huawei, Xiaomi flagship models) and watch displays, combining scratch resistance with aesthetic appeal.

Camera protective lenses for dust and scratch protection.

2. Defense & Aerospace:

Missile infrared domes, enduring high-temperature shocks and sand erosion for precision guidance.

UAV electro-optical pod windows for rugged battlefield conditions.

3. Medical Devices:

Endoscope protective windows, resistant to bodily fluids and sterilization cycles.

Laser therapy device optics, ensuring accurate beam transmission.

4. Industrial & Energy:

Semiconductor etching chamber observation windows, resistant to corrosive environments.

High-temperature furnace monitoring windows (1900°C continuous operation).

5. Automotive Tech:

HUD display optics for enhanced driving safety.

LiDAR system windows for autonomous vehicles, optimized for thermal and environmental resilience.

Key Advantages of Custom-Shaped Sapphire Windows

1. Exceptional Physical Performance

Custom-shaped sapphire windows are crafted from high-purity alumina (α-Al₂O₃), boasting Mohs hardness of 9, offering scratch resistance 3x greater than traditional glass to withstand abrasion from sand, metal friction, and extreme conditions. Their high-temperature resistance(melting point: 2050°C, sustained operational temperature up to 1900°C) makes them ideal for high-temperature furnace monitoring and aerospace thermal protection. With a low thermal expansion coefficient (5.3×10⁻⁷/°C), they maintain optical stability under thermal stress, far surpassing quartz glass.

2. Design Flexibility for Customization

Supporting complex geometric configurations, including curved surfaces, stepped holes, and blind slots, with minimum bore diameter as small as 50μm and machining precision ±0.01mm, these windows meet stringent requirements for medical endoscopes and LiDAR systems. Drawing-to-production services enable clients to submit CAD files or 3D models, leveraging CNC laser cutting and diamond grinding for rapid prototyping without molds, reducing product development cycles by over 50%.

3. Multi-Scenario Adaptability

Spanning ultraviolet (0.15μm) to mid-infrared (5.5μm) wavelengths, these windows achieve >85% light transmittance, making them suitable for precision applications like optoelectronic sensing and laser transmission. Their chemical inertness (resistance to strong acids/alkalis) and radiation resistance (ISO 9001 certified) allow deployment in chemical reactors and nuclear plant monitoring systems, lowering maintenance costs by >30% compared to conventional materials.

4. Lightweight Design with Enhanced Durability

Compared to bulk sapphire crystals, these windows adopt precision grinding techniques to achieve ultra-thin profiles (0.3–100mm thickness), reducing weight by 40% versus traditional optical glass. Combined with nanocoating reinforcement (e.g., diamond-like carbon DLC coating), surface hardness reaches Mohs 10, improving wear resistance 5x and extending lifespan to 100,000+ hours for high-frequency applications like smartphone screens and wearable devices.

5. Cost-Efficiency and Sustainability

Leveraging crystal growth technologies(e.g., Czochralski method), raw material utilization exceeds 95%, cutting costs by 60%versus natural sapphire mining. Recyclable through plasma melting, these windows align with EU RoHS/REACH standards, supporting corporate ESG goals while minimizing environmental impact.

XKH Services & Supply Chain Excellence

Our end-to-end service model integrates customer requirements from design to delivery, supported by ERP systems for real-time tracking. We offer 48-hour prototyping and 15-day bulk production, backed by a smart factory equipped with laser cutting machines and grinding systems, achieving ±0.005mm cutting precision and 40% faster micro-hole processing. Value-added services include AR/HR coatings and custom branding.