Custom-Shaped Sapphire Optical Windows Single Crystal Al₂O₃ Wear Resistant Bespoke Dimensions Or Shape

Technical parameters

Sapphire window |

|

Dimension |

8-400mm |

Dimensional tolerance |

+0/-0.05mm |

Surface quality(scratch&dig) |

40/20 |

Surface accuracy |

λ/10per@633nm |

Clear Aperture |

>85%,>90% |

Parallelism tolerance |

±2''-±3'' |

Bevel |

0.1-0.3mm |

Coating |

AR/AF/upon customer request |

Key Features and Advantages of Custom-Shaped Sapphire Windows

1. Exceptional Hardness and Wear Resistance

Custom-shaped sapphire windows are manufactured from high-purity single-crystal Al₂O₃ material, achieving a Mohs hardness rating of 9 - second only to diamond's perfect 10. This extraordinary hardness endowment enables our sapphire windows to demonstrate unparalleled scratch resistance, with wear resistance exceeding standard soda-lime glass by 200 times and tempered glass by 20 times. In practical applications, these custom-shaped sapphire windows effectively withstand abrasion from daily contaminants including sand particles and metal tools, making them ideal for high-wear environments such as smartphone screen protectors and industrial equipment viewports.

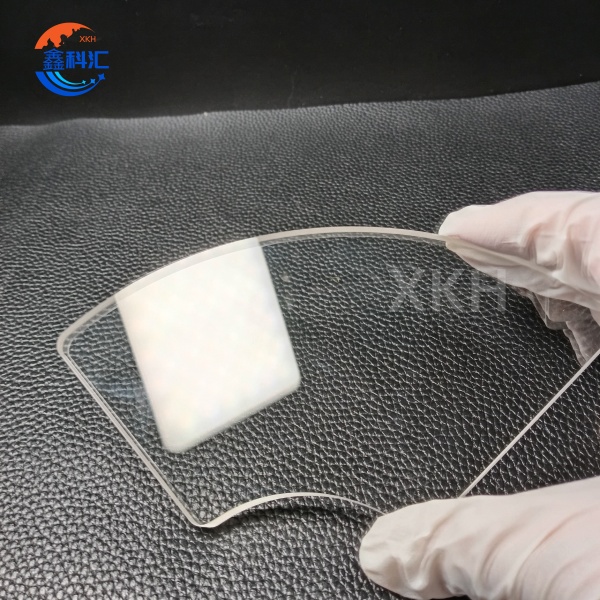

2. Superior Optical Performance

The custom-shaped sapphire windows exhibit outstanding optical characteristics, maintaining over 85% transmittance across a broad spectral range of 400-5000nm, with average visible light transmission (380-780nm) reaching 90%. With refractive indices between 1.76-1.78 and birefringence below 0.008, these exceptional optical parameters establish our custom-shaped sapphire windows as the premium choice for high-end optical instruments. Through proprietary polishing techniques, we achieve surface roughness below Ra 0.5nm, significantly reducing light scattering losses. Furthermore, we've developed multiple functional optical coatings for these windows, including broadband anti-reflection coatings and cut-off filters, substantially expanding their optical application potential.

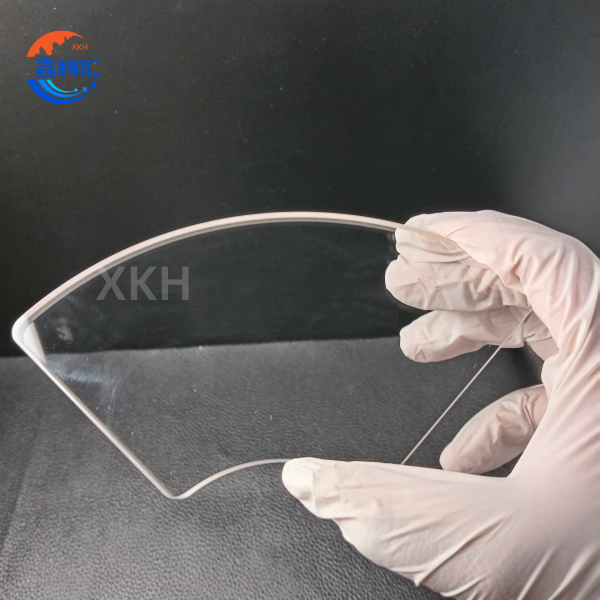

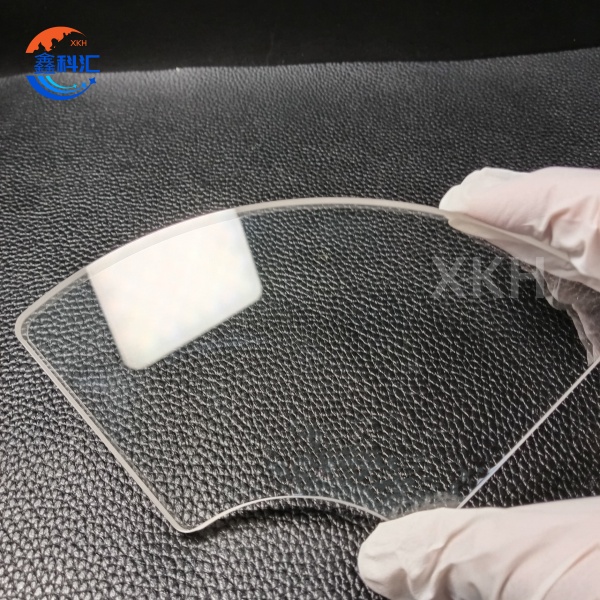

3. Complex Geometry Customization Capabilities

Leveraging advanced manufacturing technologies, we provide comprehensive customization services for custom-shaped sapphire windows with complex geometries. From basic circular and rectangular profiles to intricate polygonal shapes, curved surfaces, and specialized configurations incorporating micro-holes or channels - all can be precision-engineered.

4. Environmental Stability

The custom-shaped sapphire windows demonstrate remarkable environmental resilience. With a melting point of 2053°C, they maintain structural integrity at temperatures up to 1800°C for short durations. The thermal expansion coefficient of 7.5×10⁻⁶/K ensures dimensional stability across an operational temperature range of -60°C to 300°C.

5. Cost Efficiency Advantages

Our custom-shaped sapphire windows offer significant cost benefits. Through optimized production processes and economies of scale, we've established a highly efficient supply chain capable of delivering standard products within 7-15 days. For urgent R&D projects, we provide expedited services with sample delivery in as little as 72 hours. These competitive advantages make our custom-shaped sapphire windows particularly attractive for large-scale commercial applications.

Primary Application of Custom-Shaped Sapphire Windows

1. Consumer Electronics:

Smartphone/smartwatch screen covers and camera lens protectors utilize the scratch-resistant properties of custom-shaped sapphire windows to extend device lifespan.

2. Optical Instruments:

Laser system windows, spectrometer lenses, and infrared thermal imaging lenses rely on their high light transmittance and high-temperature resistance.

3. Industrial Equipment:

Barcode scanner windows and semiconductor equipment viewports require the wear resistance and chemical stability of custom-shaped sapphire windows.

4. Defense & Aerospace:

Missile seeker domes and satellite optical payloads demand materials that maintain performance stability in extreme environments.

5. Medical Devices:

Endoscope protective lenses and surgical laser guidance windows require biocompatibility and sterile surface treatment.

XKH Services of Custom-Shaped Sapphire Windows

1. Supply Chain Advantages:

As a direct manufacturer with in-house crystal growth facilities and CNC machining centers, we ensure full-process control from raw materials to finished products for custom-shaped sapphire windows, offering prices more than 20% lower than distributors.

2. Customization Services:

We support CAD/sample-based processing, providing 3D modeling, prototype sampling (3-5 days), and small-batch trial production (minimum order 10-30 pieces).

3. Technical Support:

Complimentary optical design consultation to optimize thickness and coating solutions (e.g., anti-reflective, hydrophobic coatings) for custom-shaped sapphire windows.

4. Rapid Delivery:

Standard sizes ship within 7 days; complex geometries completed in 2-4 weeks, with global air freight support.

5. Quality Assurance:

Each custom-shaped sapphire window undergoes rigorous inspection including interferometer (surface profile) and spectrophotometer (transmittance) testing, accompanied by material certification and RoHS compliance documentation.