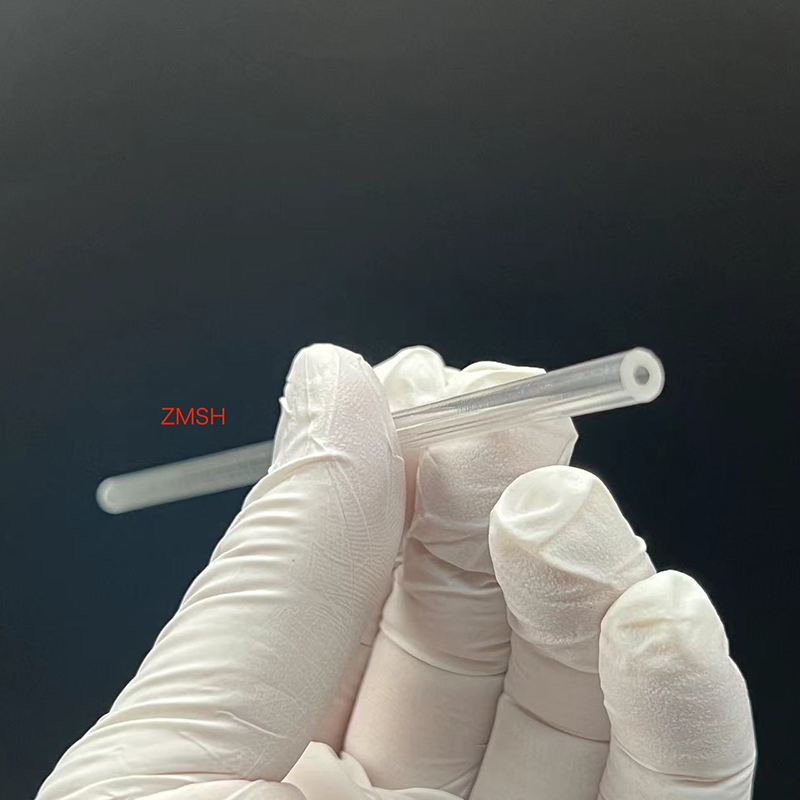

Sapphire Tube for Thermocouple Protection – High-Temperature Precision in Harsh Environments

Detailed Diagram

Introduction

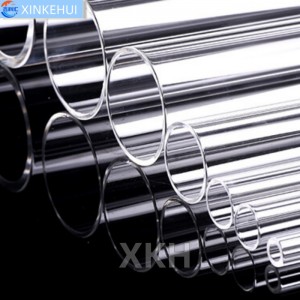

Sapphire tubes, made from single-crystal aluminum oxide (Al₂O₃), are high-performance components widely used in a variety of industrial applications. Their unmatched combination of thermal resistance, mechanical strength, chemical stability, and optical transparency has made them a staple in extreme environment systems. One of the most valuable and increasingly adopted applications is in the protection of thermocouples—temperature-sensing devices that often operate in aggressive, high-temperature, or corrosive conditions. This article provides an in-depth overview of sapphire tube properties, core characteristics, key applications, and especially their role in thermocouple protection.

Why Do Sapphire Tubes Offer Such High Performance?

Sapphire tubes are known for their ability to maintain structural and functional stability under extreme physical and chemical stress. In high-pressure systems, they are used as both containment vessels and observation windows, offering a secure and inert environment for analyzing fluids and gases. Due to their high compressive strength and scratch resistance, sapphire tubes are also suited to environments that involve strong mechanical impact or frequent thermal cycling.

These tubes are unique in their ability to operate at temperatures up to 2000°C without softening or deforming. Unlike many other ceramic or glass materials, sapphire retains its shape and mechanical properties even at elevated temperatures. This performance is critical in applications where consistent physical dimensions are essential for sealing, insulation, or alignment—such as in thermocouple housing systems.

Their optical transparency across a broad spectrum—from ultraviolet (0.3 μm) through visible to infrared (5 μm)—adds another layer of functionality. This feature allows sapphire tubes not only to act as structural components but also to support integrated optical systems for real-time monitoring and laser-based measurements.

Sapphire Tubes in Thermocouple Protection

Thermocouples are essential temperature sensors used across industries ranging from aerospace and metallurgy to semiconductor fabrication and chemical processing. However, thermocouples are sensitive instruments that can degrade quickly when exposed directly to reactive gases, plasma environments, or rapid heating/cooling cycles. To prevent these issues, sapphire tubes serve as ideal protective sheaths for thermocouples.

The thermal conductivity of sapphire ensures fast and accurate heat transfer to the thermocouple inside the tube, allowing real-time temperature monitoring while shielding the sensor from corrosive elements, mechanical abrasion, and thermal shock. This balance of insulation and conduction makes sapphire tubes uniquely suited to thermocouple protection in hostile environments.

In addition, sapphire’s chemical inertness prevents any contamination of the process environment. This is particularly important in high-purity applications such as semiconductor wafer processing, medical sterilization systems, or high-vacuum thermal chambers. The absence of reaction between the sapphire and aggressive chemicals like fluorine plasma, hydrochloric acid, or molten metals ensures both system reliability and measurement accuracy.

Moreover, sapphire tubes are highly resistant to wear and do not degrade under prolonged exposure to high-energy particles or intense UV/IR radiation. This robustness extends the lifespan of thermocouple sensors, reducing maintenance costs and system downtime.

Broader Applications of Sapphire Tubes

While thermocouple protection is one of the standout applications, sapphire tubes are also widely used in other high-tech and industrial fields. These include:

-

Plasma Processing: Sapphire tubes act as enclosures in plasma etching and deposition systems, where their chemical resistance prevents particle generation.

-

High-Temperature Lighting: Their transparency and thermal resistance make them ideal envelopes for UV, visible, and IR lamp assemblies.

-

Water Treatment and Gas Injection: Sapphire tubes are employed in systems where precise control of fluids or gases under high pressure is required.

-

Medical and Pharmaceutical Equipment: Due to their bio-inert properties, sapphire tubes are safe for use in sterilized or implantable devices.

-

Spectroscopy and Optical Analysis: Their optical clarity allows for seamless integration into spectroscopy systems for chemical or biological sensing.

In all these fields, sapphire tubes deliver outstanding mechanical durability and chemical resistance, ensuring performance longevity under extreme working conditions.

Core Characteristics of Sapphire Tubes

Sapphire tubes possess a rare combination of desirable material properties:

-

Wide Optical Transmission Range: From 0.3 μm (UV) to 5 μm (IR), suitable for laser systems, optical monitoring, and in-situ measurements.

-

Extreme Hardness: With a Mohs hardness of 9, sapphire is virtually scratchproof, only surpassed by diamond.

-

High Melting Point: Sapphire remains structurally stable up to 2030°C.

-

Exceptional Thermal Conductivity: Efficiently transfers heat, vital for thermocouple applications.

-

Chemical Stability: Resistant to acids, alkalis, and molten metals, except hot caustic salts.

-

High Electrical Insulation: Ideal for electronic and high-voltage insulation.

-

Dimensional Stability: Maintains integrity under thermal stress or mechanical load.

Benefits of Using Sapphire Tubes for Thermocouples

The integration of sapphire tubes in thermocouple assemblies brings numerous advantages:

-

Improved Sensor Accuracy: Thermal conductivity supports rapid temperature sensing.

-

Extended Sensor Lifespan: Resistance to corrosion and abrasion protects the inner thermocouple.

-

Reduced Downtime: Lower frequency of sensor failure and recalibration needs.

-

System Purity: Chemical inertness prevents contamination, essential for cleanroom processes.

-

Multi-functionality: Combines thermal protection with optical transparency for dual-use in sensing and inspection.

Conclusion

The integration of sapphire tubes in thermocouple assemblies brings numerous advantages:

-

Improved Sensor Accuracy: Thermal conductivity supports rapid temperature sensing.

-

Extended Sensor Lifespan: Resistance to corrosion and abrasion protects the inner thermocouple.

-

Reduced Downtime: Lower frequency of sensor failure and recalibration needs.

-

System Purity: Chemical inertness prevents contamination, essential for cleanroom processes.

-

Multi-functionality: Combines thermal protection with optical transparency for dual-use in sensing and inspection.