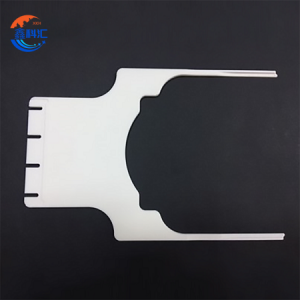

Alumina Ceramic End Effector / Fork Arm for Wafer and Substrate Handling

Detailed Diagram

Overview of Alumina Ceramic End Effector

The Alumina Ceramic End Effector, commonly referred to as a ceramic fork arm or ceramic gripper, is a critical tool used in robotic automation and cleanroom production lines. Alumina Ceramic End Effector is installed on the robotic arm as the final interface with the product, responsible for picking, holding, aligning, and transferring highly sensitive parts such as silicon wafers, glass panels, or microelectronic components.

Manufactured from ultra-pure alumina ceramic (Al2O3), this fork arm provides an exceptionally clean and stable solution for environments where metal contamination, plastic deformation, or particle generation cannot be tolerated.

Material Properties – Why Alumina

About Alumina Ceramic End Effector,Alumina (Al2O3) is one of the most established and reliable advanced engineering ceramics. The grade we use (≥99.5% purity) offers a unique combination of physical and chemical qualities that make it the material of choice for semiconductor and vacuum applications:

-

Extreme hardness – With a Mohs hardness rating of 9, it offers long-lasting durability and scratch resistance.

-

Thermal endurance – Maintains structural integrity beyond 1600°C, outperforming metal and polymer counterparts.

-

Electrical insulation – Eliminates static buildup and provides full dielectric protection.

-

Chemical immunity – Unaffected by acids, alkalis, plasma gases, and aggressive cleaning solutions.

-

Ultra-low contamination risk – Non-outgassing, low-friction surface that minimizes particle release in cleanrooms.

These attributes allow alumina ceramic end effectors to operate flawlessly in harsh, high-precision environments.

Core Applications of Alumina Ceramic End Effector

The versatility of alumina ceramic end effectorfork arms makes them essential in multiple high-tech industries:

-

Semiconductor wafer transport systems – Securely moving silicon wafers from process to process without micro-scratches.

-

Flat panel display production – Handling fragile glass substrates for OLED, LCD, or microLED fabrication.

-

Photovoltaic (PV) manufacturing – Supporting solar wafer loading and unloading under high-speed robotic cycles.

-

Optical and electronic component assembly – Gripping delicate parts like sensors, resistors, and miniature chips.

-

Vacuum and cleanroom automation – Performing precision tasks in ultra-clean, particle-controlled conditions.

In every scenario, the Alumina Ceramic End Effector provides the crucial link between robotic automation and the product being moved.

Design and Customization Options of Alumina Ceramic End Effector

Every production line has unique requirements. Therefore, we provide tailor-made Alumina Ceramic End Effector solutions for different wafer sizes, robotic systems, and handling methods:

Wafer compatibility: Handles wafers from 2” to 12” and can be scaled for custom parts.

Geometry options: Single fork, dual fork, multi-slot, or custom shapes with integrated recesses.

Vacuum handling: Optional vacuum suction channels for contactless wafer support.

Mounting interfaces: Custom bolt holes, flanges, or slotted designs to fit any robotic arm.

Surface finishes: Polished or super-finished surfaces (down to Ra < 0.15 μm).

Edge profiles: Chamfered or rounded edges for maximum wafer protection.

Our Alumina Ceramic End Effector engineering team can work from customer CAD drawings or sample parts, ensuring seamless integration into existing automation systems.

Key Benefits of Alumina Ceramic End Effectors

| Feature | Why It Matters |

|---|---|

| Dimensional precision | Keeps perfect alignment even in high-speed, repetitive cycles. |

| Non-contaminating | Produces virtually no particles, meeting strict cleanroom needs. |

| Heat and corrosion proof | Endures aggressive processing steps and thermal shocks. |

| No static charge | Protects sensitive wafers and components from electrostatic risk. |

| Lightweight but rigid | Offers high stiffness without compromising robotic arm load. |

| Extended service life | Outperforms metal and polymer arms in lifespan and reliability. |

Material Comparison of Alumina Ceramic End Effector

| Attribute | Plastic Fork Arm | Aluminum/Metal Fork Arm | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Hardness | Low | Medium | Very High |

| Thermal Range | ≤ 150°C | ≤ 500°C | Up to 1600°C |

| Chemical Stability | Poor | Moderate | Excellent |

| Cleanroom Rating | Low | Average | Ideal for Class 100 or better |

| Wear Resistance | Limited | Good | Outstanding |

| Customization Level | Moderate | Limited | Extensive |

Frequently Asked Questions(FAQ)of Alumina Ceramic End Effector

Q1: What makes an alumina ceramic end effector different from a metal one?

A1: Unlike aluminum or steel arms, alumina ceramic does not corrode, deform, or introduce metallic ions into semiconductor processes. It remains dimensionally stable under extreme conditions and releases virtually no particles.

Q2: Can these Alumina Ceramic End Effector be used in high-vacuum and plasma chambers?

A2: Yes. Alumina ceramic is non-outgassing and resistant to plasma, which makes it a preferred material for vacuum processing and etching equipment.

Q3: How customizable are these Alumina Ceramic End Effector fork arms?

A3: Every unit can be fully customized—including shape, slots, suction holes, mounting style, and edge finish—to match your robotic system’s requirements.

Q4: Are they fragile?

A4: While ceramic has natural brittleness, our design engineering distributes load evenly and minimizes stress points. When handled correctly, the service life often exceeds that of metal or polymer alternatives.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.