Adjustable Wafer Box – One Solution for Multiple Wafer Sizes

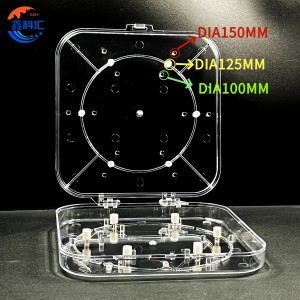

Detailed Diagram of Adjustable Wafer Box

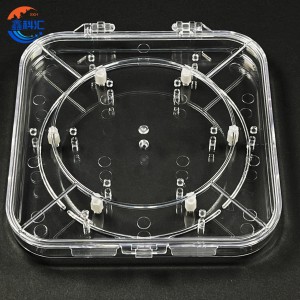

Overview of Adjustable Wafer Box

The Adjustable Wafer Box is a versatile storage and transport container designed to meet the demanding requirements of the semiconductor industry. Unlike fixed-size wafer carriers that can only hold a single wafer dimension, this Adjustable Wafer Box features an adjustable support system that can securely accommodate wafers of different diameters and thicknesses in a single container.

Built with high-purity, transparent polycarbonate (PC), the Adjustable Wafer Box offers exceptional clarity, cleanliness, and durability, making it ideal for cleanroom environments where contamination control is critical. Whether used in fabrication plants, research labs, or wafer distribution, this box ensures wafers are always handled safely and efficiently.

Key Product Features of Adjustable Wafer Box

-

Universal Fit Design – The repositionable pegs and modular slots allow one Adjustable Wafer Box to handle multiple wafer sizes, from small R&D wafers to full-size production wafers.

-

Transparent Construction – The Adjustable Wafer Box made of clear PC material, allowing operators to inspect wafers without opening the box, reducing handling and contamination risk.

-

Protective & Durable – The robust structure provides impact resistance and protects wafer edges from chips, scratches, and dust during transport.

-

Cleanroom Ready – Low particle generation and high chemical resistance make it suitable for ISO Class 5–7 environments.

-

User-Friendly Flip Top Lid – A hinged closure keeps the lid secure while making it easy to open and close during wafer loading and unloading.

Applications of Adjustable Wafer Box

Semiconductor Manufacturing Plants – For wafer handling during production stages such as cleaning, inspection, thin film deposition, and lithography.

Research & Development Laboratories – Ideal for universities, institutes, and startups handling various wafer sizes in experimental work.

Testing & Quality Control Facilities – Streamlines wafer organization and transfer for measurement, metrology, and failure analysis.

International Shipping & Logistics – Provides a secure and cost-efficient packaging solution for wafer exports, minimizing the need for multiple box sizes.

Frequently Asked Questions (FAQ) of Adjustable Wafer Box

Q1: Why choose a polycarbonate Adjustable Wafer Box instead of acrylic?

PC offers superior impact strength and will not shatter, while acrylic (PMMA) can crack under stress.

Q2: Can PC withstand cleanroom cleaning agents?

Yes. PC tolerates IPA and other solvents used for standard cleaning, but strong alkalis should be avoided for prolonged exposure.

Q3: Is the Adjustable Wafer Box suitable for fully automated wafer handling?

Many PC wafer boxes, including this design, can be adapted for manual or robotic handling, depending on production requirements.

Q4: Can Adjustable Wafer Box be reused multiple times?

Absolutely. PC boxes are reusable for dozens or even hundreds of cycles, making them cost-effective and eco-friendly.

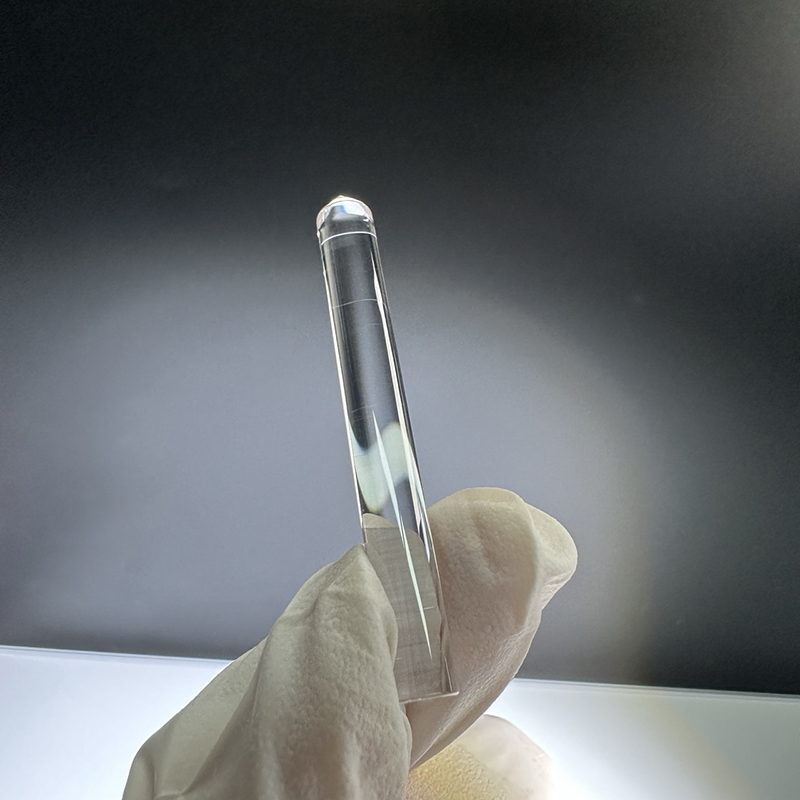

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.