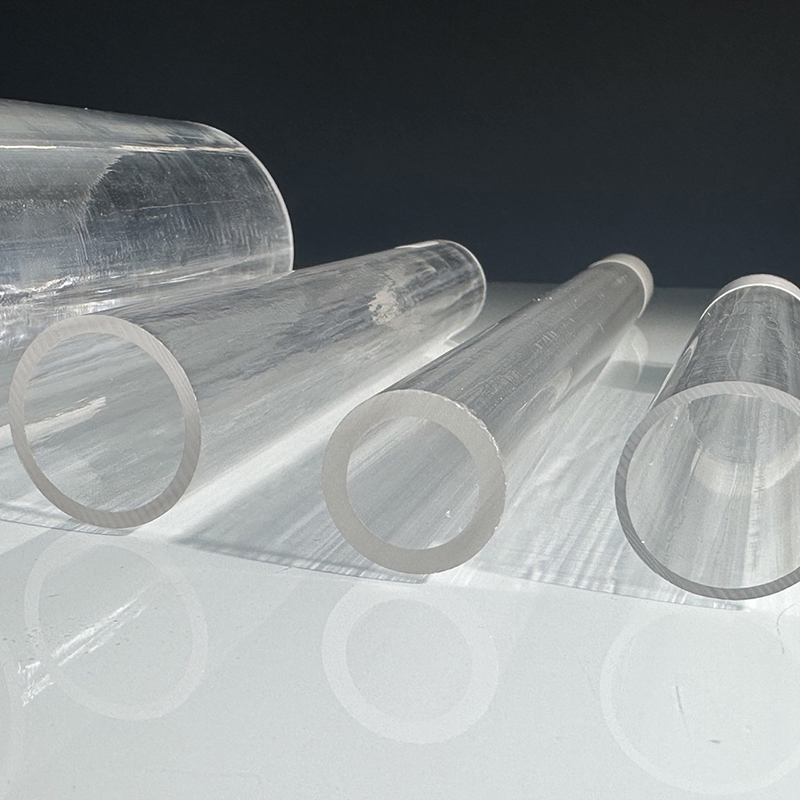

Fused Quartz Tubes Customizable Sizes for Industrial and Laboratory Use

Detailed Diagram

Product Overview

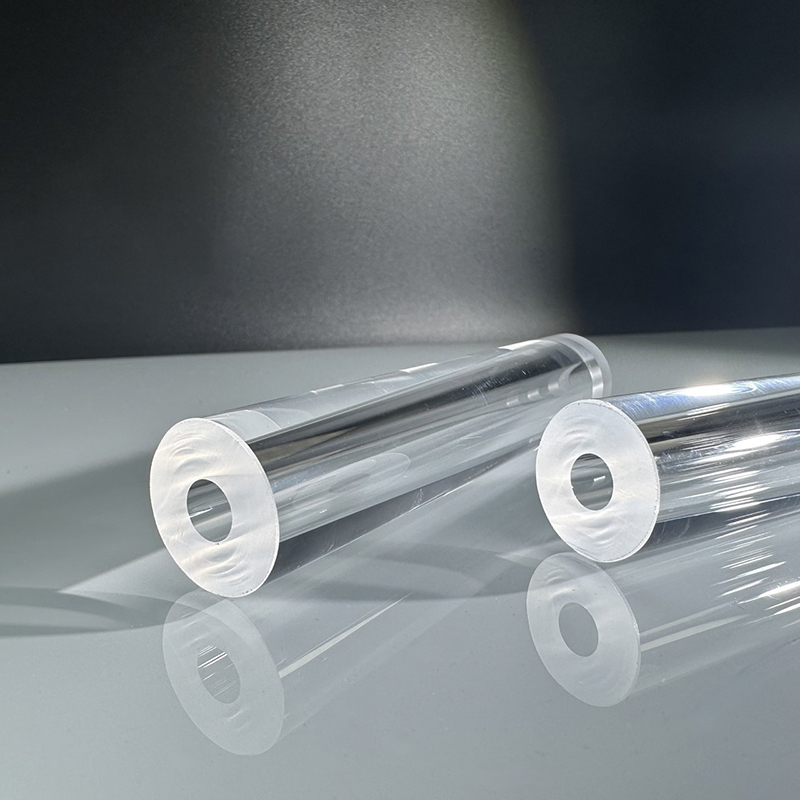

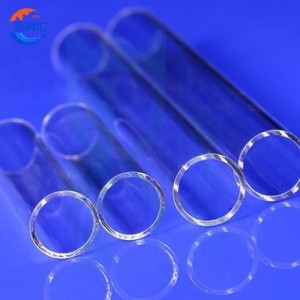

Fused quartz tubes are precision-engineered silica glass products manufactured by melting high-purity crystalline silicon dioxide (SiO₂) into an amorphous, non-crystalline form. Known for their exceptional thermal stability, optical clarity, low thermal expansion, and superior chemical resistance, fused quartz tubes are widely used in demanding industries such as semiconductors, photovoltaics, laboratories, optical communication, metallurgy, and advanced manufacturing.

These tubes are available in various diameters, lengths, wall thicknesses, and configurations, offering unmatched versatility for both standard and custom applications. Whether used for high-temperature furnace operations, optical components, or fluid containment in ultra-pure environments, fused quartz tubing delivers consistent performance where reliability and purity are critical.

Manufacturing Technology

Fused quartz tubes are typically produced using one of the following two methods:

1. Electric Fusion

Electric fusion involves heating naturally derived quartz sand in an electric arc furnace to produce translucent or clear quartz tubes. This method ensures excellent thermal uniformity and dimensional control, making it suitable for general industrial and scientific uses.

2. Flame Fusion (Continuous Fusion)

Flame fusion uses a high-temperature hydrogen-oxygen flame to continuously melt quartz into a glassy tube form. This technique produces tubes with superior clarity and minimal impurities, particularly suitable for optical and semiconductor applications where transmission and cleanliness are paramount.

In addition, some fused quartz tubes are made from synthetic silica, offering even higher UV transparency, better purity (typically >99.995% SiO₂), and lower OH (hydroxyl) content. These are ideal for deep-UV and high-precision optical processes.

Key Features and Performance Benefits

-

Ultra-high purity: SiO₂ content ≥ 99.99%, with low levels of metallic and alkali impurities.

-

Outstanding thermal performance: Can endure continuous operation at temperatures up to 1100°C, and short-term exposure up to 1300°C.

-

Low thermal expansion: Approx. 5.5 × 10⁻⁷/°C, minimizing thermal stress and deformation.

-

Excellent thermal shock resistance: Can tolerate rapid temperature changes without cracking or structural damage.

-

High optical transmission: Especially in the UV and IR regions, depending on tube grade.

-

Superior chemical resistance: Inert to most acids and corrosive gases, suitable for reactive environments.

-

Electrical insulation: High dielectric strength, ideal for electronic insulation in high-voltage applications.

Standard Specifications

| Parameter | Specification |

|---|---|

| Outer Diameter (OD) | 1 mm – 300 mm (custom sizes available) |

| Wall Thickness | 0.5 mm – 10 mm |

| Tube Length | Standard up to 2000 mm; longer lengths customizable |

| Material Purity | ≥ 99.99% SiO₂ |

| Optical Grade Options | Transparent / Translucent / UV-grade / Synthetic |

| Surface Finish | Fire-polished or precision-ground |

| Shape Availability | Straight, bent, coiled, flanged, closed-end |

Applications

Fused quartz tubes are an essential material in many high-performance applications due to their purity and thermal resistance:

Semiconductor Industry

-

CVD and diffusion furnace tubes

-

Wafer processing chambers

-

Quartz liners and shielding tubes

Laboratory Equipment

-

High-temperature reaction tubes

-

Sample containers and flow cells

-

Spectroscopy and UV exposure chambers

Optical and Photonics

-

Laser and lamp housings

-

UV and IR light guides

-

Fiber optic preform protection tubes

High-Temperature Industrial Uses

-

Heating element sleeves

-

Quartz crucibles and tube furnaces

-

Chemical vapor transport processes

Lighting and Disinfection

-

Germicidal UV lamp tubes

-

Xenon, halogen, and mercury lamp envelopes

-

Quartz sleeves for LED sterilizers and reactors

Frequently Asked Questions (FAQ)

Q1: What’s the difference between transparent and translucent quartz tubes?

A1: Transparent tubes are clear and optically pure, suitable for UV transmission and visual monitoring. Translucent (milky) quartz is less clear but offers better thermal insulation and is often used in heating or diffusion processes.

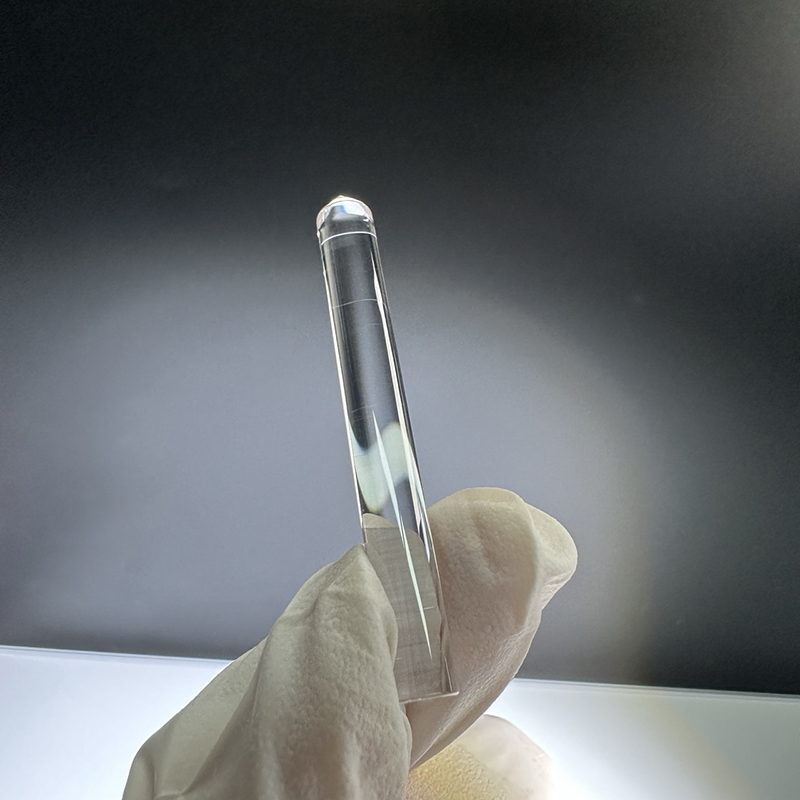

Q2: Can you provide custom shapes or ends, like flared or closed ends?

A2: Yes, we offer full customization services. We can provide tubes with closed ends, flanged ends, side arms, and other modifications according to your CAD drawings or specifications.

Q3: Are your quartz tubes suitable for high-vacuum systems?

A3: Absolutely. Our high-purity quartz tubes exhibit low outgassing, making them suitable for ultra-high vacuum (UHV) and cleanroom environments.

Q4: What’s the maximum temperature these tubes can handle?

A4: Our fused quartz tubes can be used continuously at temperatures up to 1100°C, with short-term resistance up to 1300°C, depending on the application and heating rate.

Q5: Do you supply quartz tubes for UV sterilization equipment?

A5: Yes. We manufacture high-transmittance UV-grade quartz tubes specifically designed for germicidal UV-C lamps and water sterilization systems.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.