115mm Ruby Rod: Extended-Length Crystal for Enhanced Pulsed Laser Systems

Detailed Diagram

Overview

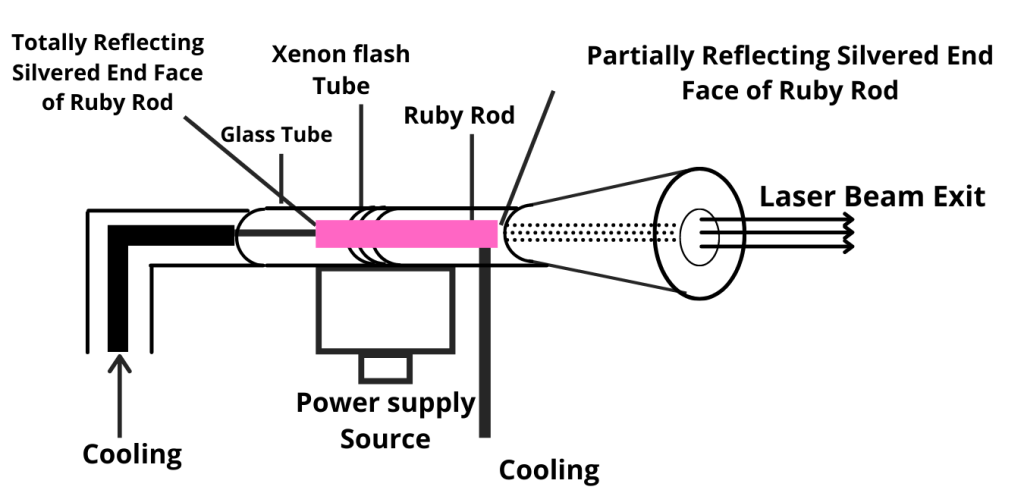

The 115mm ruby rod is a high-performance, extended-length laser crystal designed for pulsed solid-state laser systems. Constructed from synthetic ruby—an aluminum oxide matrix (Al₂O₃) infused with chromium ions (Cr³⁺)—the ruby rod offers consistent performance, excellent thermal conductivity, and dependable emission at 694.3 nm. The increased length of the 115mm ruby rod compared to standard models enhances gain, allowing higher energy storage per pulse and improved overall laser efficiency.

Renowned for its clarity, hardness, and spectral properties, the ruby rod remains a valued laser material in scientific, industrial, and educational sectors. The 115mm length enables superior optical absorption during pumping, translating into brighter and more powerful red laser output. Whether in advanced laboratory setups or OEM systems, the ruby rod proves to be a reliable lasing medium for controlled, high-intensity output.

Fabrication and Crystal Engineering

The creation of a ruby rod involves controlled single-crystal growth using the Czochralski technique. In this method, a seed crystal of sapphire is dipped into a molten mix of high-purity aluminum oxide and chromium oxide. The boule is slowly pulled and rotated to form a flawless, optically uniform ruby ingot. The ruby rod is then extracted, shaped to 115mm length, and cut to precise dimensions based on the optical system’s requirements.

Each ruby rod undergoes meticulous polishing on its cylindrical surface and end faces. These faces are finished to laser-grade flatness and typically receive dielectric coatings. A high-reflective (HR) coating is applied to one end of the ruby rod, while the other is treated with a partial transmission output coupler (OC) or anti-reflection (AR) coating depending on the system design. These coatings are vital for maximizing internal photon reflection and minimizing energy loss.

Chromium ions in the ruby rod absorb pumping light, especially in the blue-green part of the spectrum. Once excited, these ions transition to metastable energy levels. Upon stimulated emission, the ruby rod emits coherent red laser light. The longer geometry of the 115mm ruby rod offers a longer path length for photon gain, which is critical in pulse-stacking and amplification systems.

Core Applications

Ruby rods, known for their exceptional hardness, thermal conductivity, and optical transparency, are widely used in high-precision industrial and scientific applications. Composed primarily of single-crystal aluminum oxide (Al₂O₃) doped with a small amount of chromium (Cr³⁺), ruby rods combine excellent mechanical strength with unique optical properties, making them indispensable in a variety of advanced technologies.

1. Laser Technology

One of the most significant uses of ruby rods is in solid-state lasers. Ruby lasers, which were among the first lasers ever developed, utilize synthetic ruby crystals as the gain medium. When optically pumped (typically using flash lamps), these rods emit coherent red light at a wavelength of 694.3 nm. Despite newer laser materials, ruby lasers are still employed in applications where long pulse duration and stable output are critical, such as in holography, dermatology (for tattoo removal), and scientific experiments.

2. Optical Instruments

Due to their excellent light transmission and resistance to scratching, ruby rods are often used in precision optical instruments. Their durability ensures long-lasting performance in harsh conditions. These rods can serve as components in beam splitters, optical isolators, and high-precision photonic devices.

3. High-Wear Components

In mechanical and metrology systems, ruby rods are utilized as wear-resistant elements. They are commonly found in watch bearings, precision gauges, and flowmeters, where consistent performance and dimensional stability are required. Ruby's high hardness (9 on the Mohs scale) allows it to withstand long-term friction and pressure without degradation.

4. Medical and Analytical Equipment

Ruby rods are sometimes used in specialized medical devices and analytical instruments. Their biocompatibility and inert nature make them suitable for contact with sensitive tissues or chemicals. In laboratory setups, ruby rods can be found in high-performance measurement probes and sensing systems.

5. Scientific Research

In physics and materials science, ruby rods are employed as reference materials for calibrating instruments, studying optical properties, or acting as pressure indicators in diamond anvil cells. Their fluorescence under specific conditions helps researchers analyze stress and temperature distributions in various environments.

In conclusion, ruby rods continue to be an essential material across industries where precision, durability, and optical performance are paramount. As advancements in material science progress, new uses for ruby rods are constantly being explored, ensuring their relevance in future technologies.

Core Specification

| Property | Value |

|---|---|

| Chemical Formula | Cr³⁺:Al₂O₃ |

| Crystal System | Trigonal |

| Unit Cell Dimensions (Hexagonal) | a = 4.785 Åc = 12.99 Å |

| X-Ray Density | 3.98 g/cm³ |

| Melting Point | 2040°C |

| Thermal Expansion @ 323 K | Perpendicular to c-axis: 5 × 10⁻⁶ K⁻¹Parallel to c-axis: 6.7 × 10⁻⁶ K⁻¹ |

| Thermal Conductivity @ 300 K | 28 W/m·K |

| Hardness | Mohs: 9, Knoop: 2000 kg/mm² |

| Young’s Modulus | 345 GPa |

| Specific Heat @ 291 K | 761 J/kg·K |

| Thermal Stress Resistance Parameter (Rₜ) | 34 W/cm |

Frequently Asked Questions (FAQ)

Q1: Why choose a 115mm ruby rod over a shorter rod?

A longer ruby rod provides more volume for energy storage and longer interaction length, resulting in higher gain and better energy transfer.

Q2: Is the ruby rod suitable for Q-switching?

Yes. The ruby rod works well with passive or active Q-switching systems and produces strong pulsed outputs when properly aligned.

Q3: What temperature range can the ruby rod tolerate?

The ruby rod is thermally stable up to several hundred degrees Celsius. However, thermal management systems are recommended during laser operation.

Q4: How do coatings affect ruby rod performance?

High-quality coatings improve laser efficiency by minimizing reflectivity loss. Improper coating can result in damage or reduced gain.

Q5: Is the 115mm ruby rod heavier or more fragile than shorter rods?

While slightly heavier, the ruby rod retains excellent mechanical integrity. It is second only to diamond in hardness and resists scratches or thermal shock well.

Q6: What pump sources work best with the ruby rod?

Traditionally, xenon flashlamps are used. More modern systems may employ high-powered LEDs or diode-pumped frequency-doubled green lasers.

Q7: How should the ruby rod be stored or maintained?

Keep the ruby rod in a dust-free, anti-static environment. Avoid handling the coated surfaces directly, and use non-abrasive cloths or lens tissue for cleaning.

Q8: Can the ruby rod be integrated into modern resonator designs?

Absolutely. The ruby rod, despite its historical roots, is still widely integrated into research-grade and commercial optical cavities.

Q9: What is the lifespan of the 115mm ruby rod?

With proper operation and maintenance, a ruby rod can function reliably for thousands of hours without degradation in performance.

Q10: Is the ruby rod resistant to optical damage?

Yes, but it’s important to avoid exceeding the damage threshold of the coatings. Proper alignment and thermal regulation preserve performance and prevent cracking.