Wire Saw Equipment for Sapphire/Ceramics/Marble Materials in Vertical/Horizontal/Multi-Wire Cutting

Detailed Diagram

Equipment Overview and Core Value

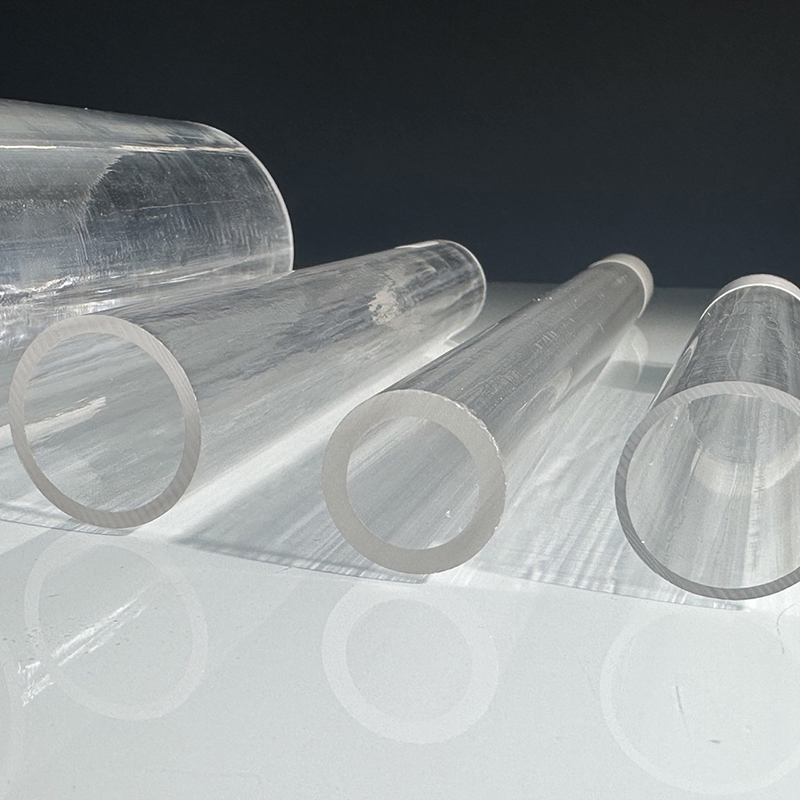

The Wire Saw Machine is a precision cutting equipment that utilizes a high-speed moving diamond wire. It forms a flexible cutting tool by fixing diamond abrasives onto a metal wire through electroplating or resin bonding, enabling efficient processing of high-hardness and high-brittleness materials. Its core value lies in achieving high-precision, low-damage cutting, while significantly improving material utilization and production efficiency. It is particularly suitable for materials like sapphire, ceramics, and marble, which are challenging for traditional processing methods.

Material Processing Characteristics and Application Directions

|

Characteristic Dimension |

Sapphire |

Ceramics |

Marble |

|

Core Characteristics |

Ultra-high hardness (Mohs 9), high brittleness |

High hardness, high brittleness, high elastic modulus |

Non-uniform material, contains hard points like quartz |

|

Processing Challenges |

Prone to cracks and edge chipping |

Cutting surface prone to micro-cracks |

Prone to uneven cutting surfaces and edge chipping |

|

Key Metrics |

Surface roughness can be controlled to Ra < 0.5μm |

Pursuit of cutting surface integrity, reducing micro-cracks |

High cutting efficiency, flat slab surface |

|

Main Application Directions |

LED substrates, optical window plates, semiconductor device substrates |

Electronic ceramic substrates, packaging materials, structural ceramics |

Architectural decorative slabs, countertops, carving crafts |

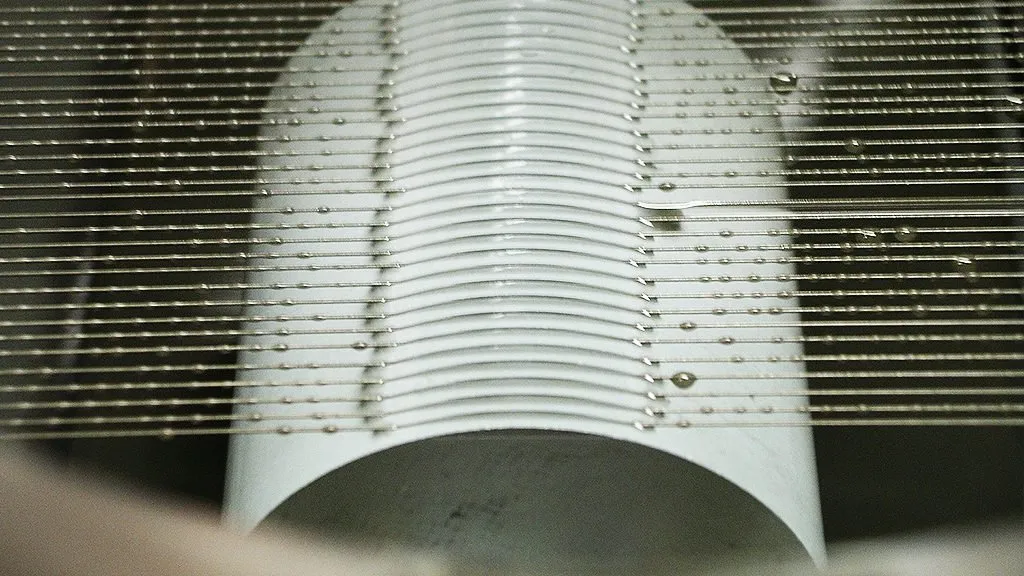

Focus on Working Principle

The core working principle of the wire saw equipment involves using a continuously circulating steel wire embedded with diamond abrasives that grinds the material through high-speed motion. The focus of this principle varies for different materials:

- Sapphire: The key lies in precise control of cutting parameters (such as wire speed, feed rate, tension) to avoid brittle fracture of the material. For example, using a diamond wire with a core diameter of 0.7mm, at a wire speed of 20m/s, feed rate of 0.5mm/min, and tension force of 50N, can achieve a cut surface with roughness below 0.5μm.

- Ceramics: It is necessary to overcome their high hardness and brittleness. The grinding action of the diamond wire saw can effectively reduce stress concentration during cutting, lowering the risk of micro-crack generation. Its processing mechanism is similar to grinding, but the abrasive particle motion path differs.

- Marble: Due to the non-uniformity of the stone, the diamond wire saw needs to possess good adaptability and chip removal capability. Modern high-speed wire saws can achieve wire speeds up to 2000 meters per minute and can dynamically adapt cutting parameters to stones of different hardness through intelligent systems.

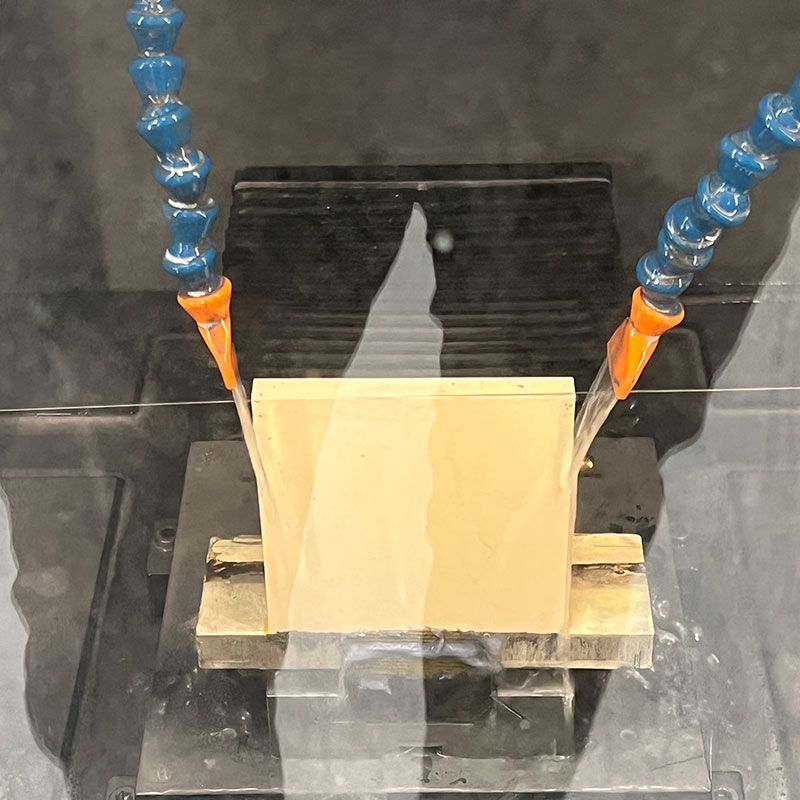

Detailed Processing Methods and Effects

|

Material |

Block Cutting/Slabbing | Cross Cutting/Trimming |

Multi-Wire Cutting |

| Sapphire | Effect: Narrow kerf (can reach 0.55mm), surface roughness controllable below 1 micrometer, effectively reducing material loss and subsequent processing. Method: Cutting crystal ingots into thin slices for making LED substrates, etc. |

Effect: Fast cutting speed; a 2-inch diameter sapphire rod can be cut in 0.5 hours. Method: Used for truncating ingots or preliminary shaping. |

Effect: Can simultaneously cut a large number of thin slices, greatly improving processing efficiency for materials like silicon wafers; sliced surfaces have good quality and uniform thickness. |

| Ceramics | Effect: Neat cutting surface, minimal edge damage, suitable for preparing standard-sized electronic ceramic substrates. Method: Used to cut ceramic blanks into substrates of desired shapes and sizes. |

Effect: Suitable for cutting special-shaped ceramic components, offering high cutting flexibility. Method: Finishing machining or profile cutting of ceramic components. |

Effect: Suitable for high-volume cutting of uniform ceramic components, high production efficiency. Method: Cutting with multiple wires simultaneously, suitable for large-scale production. |

| Marble | Effect: High cutting efficiency, flat slab surface, laying a good foundation for subsequent grinding and polishing. Method: Cutting large block materials into slabs. |

Effect: Can be used for block shaping, large slab dividing, adapting to diverse processing needs. Method: Truncating or trimming stone slabs. |

Effect: One cut can generate multiple large slabs, high production efficiency, good slab uniformity, suitable for large-scale project requirements. |

Core Parameter Table of Wire Saw Equipment

|

Name of parameter |

Parameter scale |

|

Main Motor Power |

11KW - 75KW |

|

Wire Speed |

0 - 40(m/s) |

|

Max. Wire Length |

20 - 150m |

|

Power Supply |

Standard: Three-phase, 380V, 50Hz |

|

Walking Motor Power |

0.75KW - 1.5KW |

|

Rotation Angle |

360°(Electric Control) |

|

Control |

Automatic/manual operation. Some models adopt CNC or PLC control systems. |

|

Allowed Working Temperature |

-15℃ ~ +40℃ |

XKH Service Commitment

We are committed to providing customers with comprehensive wire saw equipment solutions and technical support, leveraging the advantage of integrated industry and trade:

- Customized Equipment: Provide targeted wire saw equipment selection and configuration suggestions based on the specific materials customers process and product requirements.

- Process Optimization Support: Share cutting parameter experience for different materials to assist customers in optimizing cutting processes, improving cutting efficiency and product quality.

- Technical Support and Training: Provide equipment operation, maintenance, and other training to ensure customers can fully utilize the equipment's performance.

- Reliable After-Sales Guarantee: Establish a complete after-sales service system to respond promptly to customer needs, providing spare parts support and repair services.

FAQ of Wire Saw Equipment

Q1: What is a wire saw equipment?

A1: A wire saw is a precision cutting tool that uses a diamond-coated wire moving at high speed to slice through hard, brittle materials like sapphire, ceramics, and marble with minimal waste.

Q2: Which materials can a wire saw effectively cut?

A2: Wire saws are ideal for processing sapphire, quartz, ceramics, marble, silicon carbide, and other hard, brittle materials due to their high precision and reduced risk of cracking.

Q3: What is the difference between multi-wire and single-wire cutting?

A3: Multi-wire cutting uses multiple wires to slice large blocks into many slices simultaneously, boosting efficiency for mass production, while single-wire cutting is suited for smaller, customized cuts.

Q4: What level of cutting accuracy can a wire saw achieve?

A4: High-precision wire saws can achieve cutting accuracies within ±10μm, making them suitable for manufacturing semiconductor wafers and optical components.

Q5: How do I choose the right wire saw for my project?

A5: Select based on material hardness, project scale (e.g., multi-wire for large-volume slab production), and required precision, while also ensuring the machine offers stability and a tension control system.