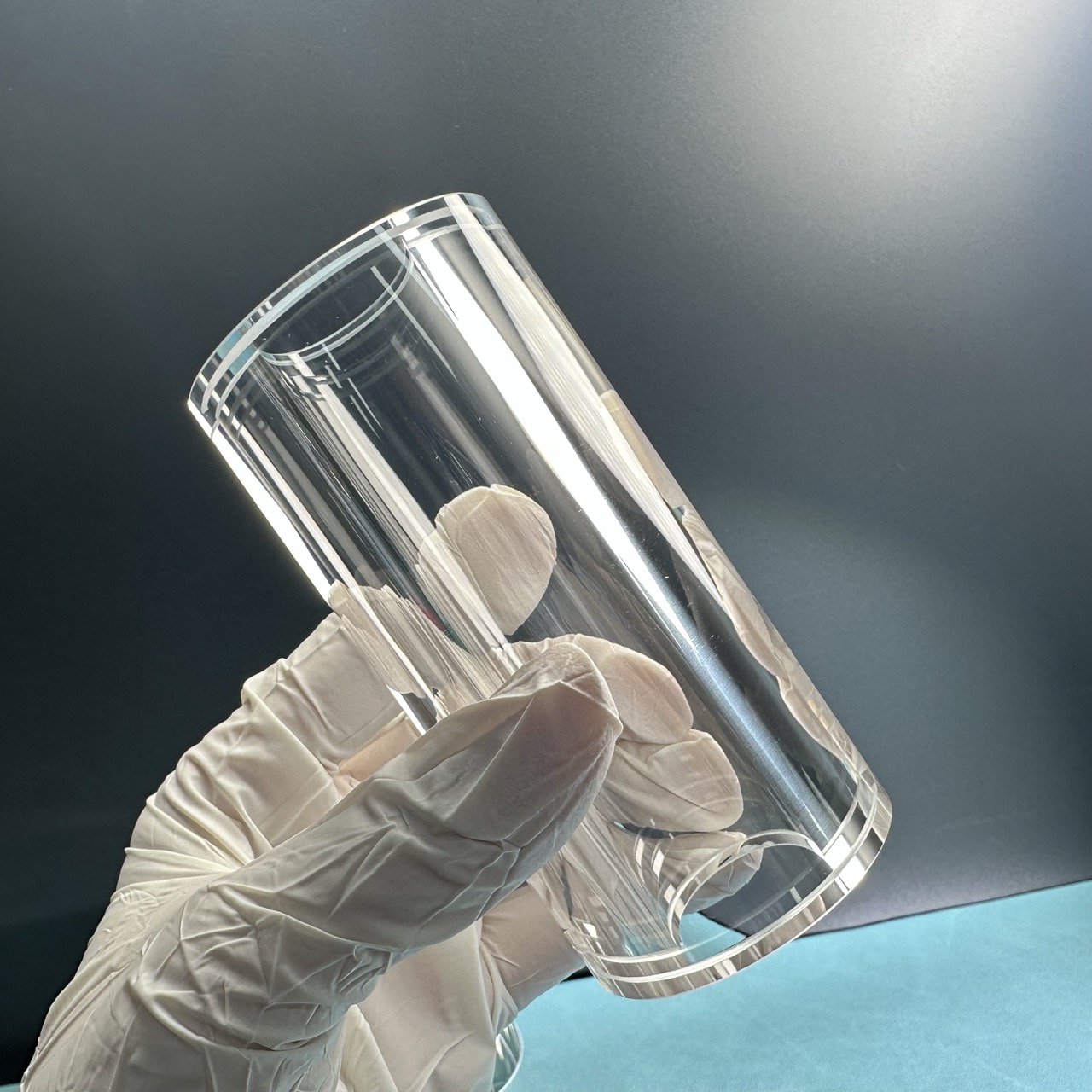

LiNbO₃ Wafers 2inch-8inch Thickness 0.1 ~ 0.5mm TTV 3µm Custom

Technical parameters

| Material | Optical Grade LiNbO3 wafes | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z etc | |

| Diameter/size | 2"/3"/4"/6"/8" | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.1 ~ 0.5mm or more | |

| Primary Flat | 16mm/22mm /32mm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| S/D | 20/10 | |

| Edge Criteria | R=0.2mm or Bullnose | |

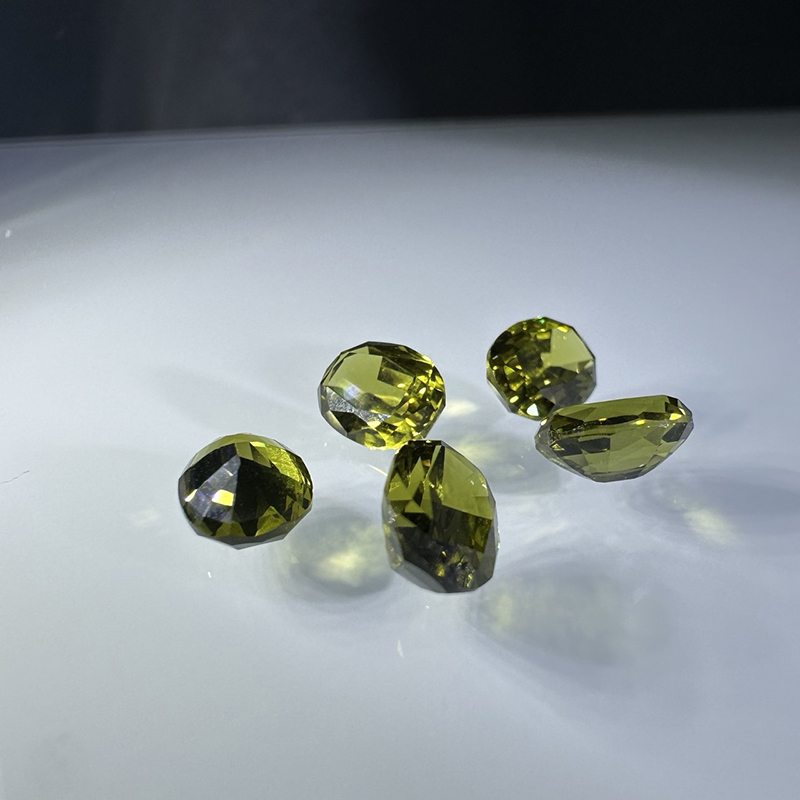

| Optical doped | Fe/Zn/MgO etc for optical grade LN< wafers | |

| Wafer Surface Criteria | Refractive index | No=2.2878/Ne=2.2033 @632nm wavelength |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

Core Attributes of Our LiNbO₃ Wafers

1.Photonic Performance Characteristics

Our LiNbO₃ Wafers exhibit extraordinary light-matter interaction capabilities, with nonlinear optical coefficients reaching 42 pm/V - enabling efficient wavelength conversion processes critical for quantum photonics. The substrates maintain >72% transmission across 320-5200nm, with specially engineered versions achieving <0.2dB/cm propagation loss at telecom wavelengths.

2.Acoustic Wave Engineering

The crystalline structure of our LiNbO₃ Wafers supports surface wave velocities exceeding 3800 m/s, permitting resonator operation up to 12GHz. Our proprietary polishing techniques yield surface acoustic wave (SAW) devices with insertion losses under 1.2dB, while maintaining temperature stability within ±15ppm/°C.

3.Environmental Resilience

Engineered to withstand extreme conditions, our LiNbO₃ Wafers maintain functionality from cryogenic temperatures to 500°C operational environments. The material demonstrates exceptional radiation hardness, withstanding >1Mrad total ionizing dose without significant performance degradation.

4.Application-Specific Configurations

We offer domain-engineered variants including:

Periodically poled structures with 5-50μm domain periods

Ion-sliced thin films for hybrid integration

Metamaterial-enhanced versions for specialized applications

Implementation Scenarios for LiNbO₃ Wafers

1.Next-Gen Optical Networks

LiNbO₃ Wafers serve as the backbone for terabit-scale optical transceivers, enabling 800Gbps coherent transmission through advanced nested modulator designs. Our substrates are increasingly adopted for co-packaged optics implementations in AI/ML accelerator systems.

2.6G RF Frontends

The latest generation of LiNbO₃ Wafers supports ultra-wideband filtering up to 20GHz, addressing the spectrum needs of emerging 6G standards. Our materials enable novel acoustic resonator architectures with Q factors surpassing 2000.

3.Quantum Information Systems

Precision-poled LiNbO₃ Wafers form the foundation for entangled photon sources with >90% pair generation efficiency. Our substrates are enabling breakthroughs in photonic quantum computing and secure communication networks.

4.Advanced Sensing Solutions

From automotive LiDAR operating at 1550nm to ultra-sensitive gravimetric sensors, LiNbO₃ Wafers provide the critical transduction platform. Our materials enable sensor resolutions down to single-molecule detection levels.

Key Advantages of LiNbO₃Wafers

1. Unparalleled Electro-Optic Performance

Exceptionally High Electro-Optic Coefficient (r₃₃~30-32 pm/V): Represents the industry benchmark for commercial lithium niobate wafers, enabling 200Gbps+ high-speed optical modulators that far surpass the performance limits of silicon-based or polymer solutions.

Ultra-Low Insertion Loss (<0.1 dB/cm): Achieved through nanoscale polishing (Ra<0.3 nm) and anti-reflection (AR) coatings, significantly enhancing the energy efficiency of optical communication modules.

2. Superior Piezoelectric & Acoustic Properties

Ideal for High-Frequency SAW/BAW Devices: With acoustic velocities of 3500-3800 m/s, these wafers support 6G mmWave (24-100 GHz) filter designs featuring insertion losses <1.0 dB.

High Electromechanical Coupling Coefficient (K²~0.25%): Enhances bandwidth and signal selectivity in RF front-end components, making them suitable for 5G/6G base stations and satellite communications.

3. Broadband Transparency & Nonlinear Optical Effects

Ultra-Wide Optical Transmission Window (350-5000 nm): Covers UV to mid-IR spectra, enabling applications such as:

Quantum Optics: Periodically poled (PPLN) configurations achieve >90% efficiency in entangled photon pair generation.

Laser Systems: Optical parametric oscillation (OPO) delivers tunable wavelength output (1-10 μm).

Exceptional Laser Damage Threshold (>1 GW/cm²): Meets stringent requirements for high-power laser applications.

4. Extreme Environmental Stability

High-Temperature Resistance (Curie point: 1140°C): Maintains stable performance across -200°C to +500°C, ideal for:

Automotive Electronics (engine compartment sensors)

Spacecraft (deep-space optical components)

Radiation Hardness (>1 Mrad TID): Compliant with MIL-STD-883 standards, suitable for nuclear and defense electronics.

5. Customization & Integration Flexibility

Crystal Orientation & Doping Optimization:

X/Y/Z-cut wafers (±0.3° precision)

MgO doping (5 mol%) for enhanced optical damage resistance

Heterogeneous Integration Support:

Compatible with thin-film LiNbO₃-on-Insulator (LNOI) for hybrid integration with silicon photonics (SiPh)

Enables wafer-level bonding for co-packaged optics (CPO)

6. Scalable Production & Cost Efficiency

6-inch (150mm) Wafer Mass Production: Reduces unit costs by 30% compared to traditional 4-inch processes.

Rapid Delivery: Standard products ship in 3 weeks; small-batch prototypes (minimum 5 wafers) deliver in 10 days.

XKH Services

1. Material Innovation Lab

Our crystal growth experts collaborate with clients to develop application-specific LiNbO₃ Wafers formulations, including:

Low optical loss variants (<0.05dB/cm)

High-power handling configurations

Radiation-tolerant compositions

2. Rapid Prototyping Pipeline

From design to delivery in 10 business days for:

Custom orientation wafers

Patterned electrodes

Pre-characterized samples

3. Performance Certification

Every LiNbO₃ Wafer shipment includes:

Full spectroscopic characterization

Crystallographic orientation verification

Surface quality certification

4. Supply Chain Assurance

Dedicated production lines for critical applications

Buffer inventory for emergency orders

ITAR-compliant logistics network