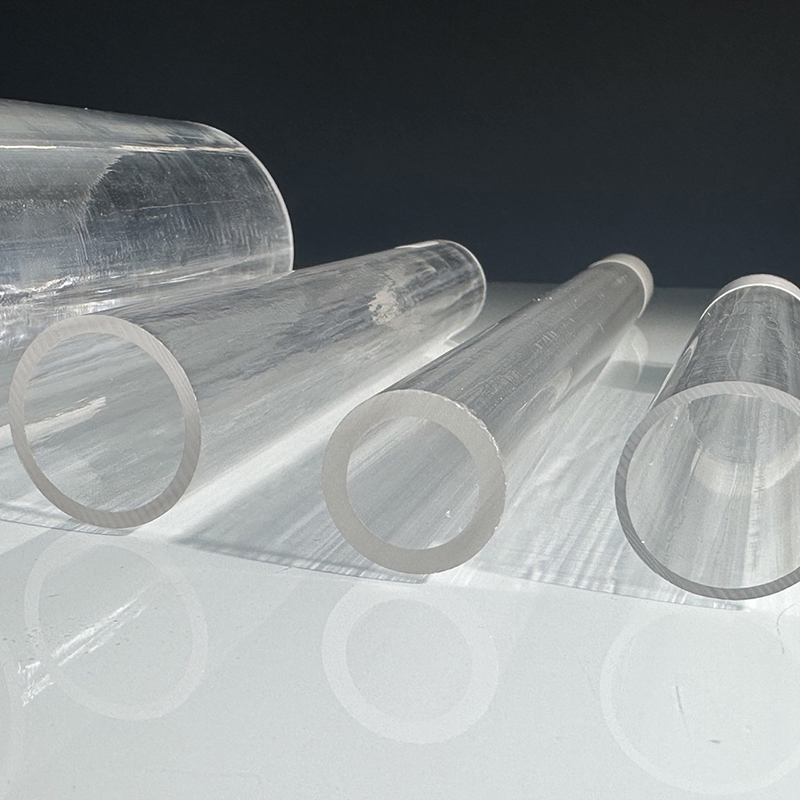

KY Sapphire Tube (Kyropoulos-Grown Sapphire Tube)

Detailed Diagram

Product Overview

KY Sapphire Tubes are high-performance tubular components manufactured from single-crystal sapphire grown by the Kyropoulos (KY) method. Compared with EFG sapphire tubes, KY sapphire tubes are typically produced by core drilling and precision machining from bulk sapphire boules, resulting in higher crystal integrity, lower internal stress, and superior optical and mechanical properties.

Thanks to the excellent intrinsic properties of sapphire—such as extreme hardness, outstanding thermal stability, high dielectric strength, and broad optical transmission—KY sapphire tubes are widely used in semiconductor processing equipment, high-temperature furnaces, optical systems, analytical instruments, and harsh-environment applications.

Manufacturing Principle (KY Method)

The Kyropoulos (KY) method is a mature and widely adopted technique for growing large, high-quality sapphire single crystals. In this process, high-purity aluminum oxide (Al₂O₃) is melted in a controlled high-temperature environment. A seed crystal is slowly introduced into the melt, allowing the sapphire crystal to grow with low thermal gradients and minimal defect density.

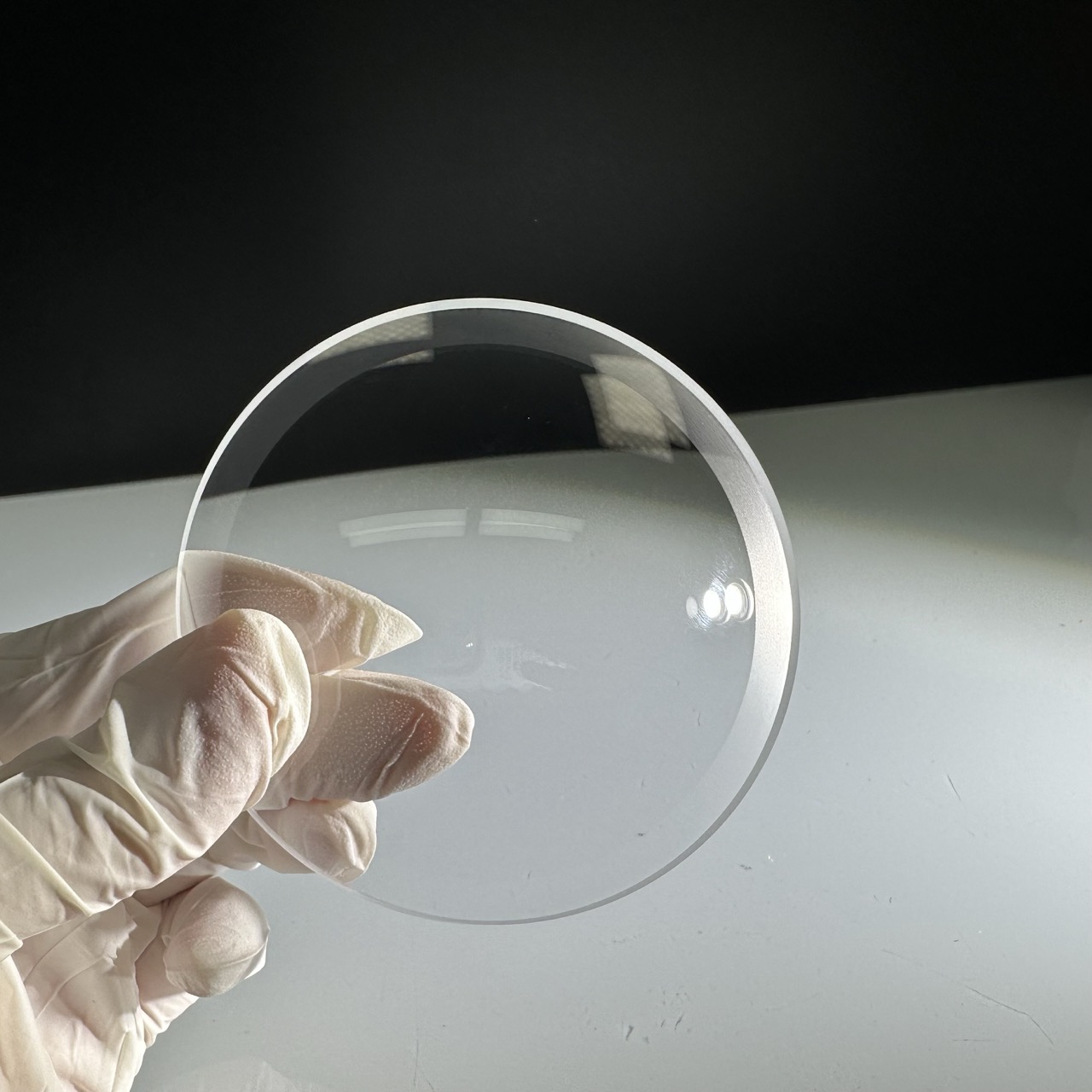

After crystal growth, KY sapphire boules are annealed to further reduce internal stress. Sapphire tubes are then fabricated through precision coring, slicing, grinding, and optional polishing processes. This indirect forming method ensures excellent crystal uniformity and enables tighter control over optical clarity, dimensional accuracy, and mechanical strength.

Key Features & Advantages

-

High Crystal Quality

KY sapphire tubes exhibit low dislocation density, minimal birefringence, and excellent structural consistency, making them suitable for demanding optical and semiconductor applications. -

Outstanding Thermal Resistance

With a melting point of approximately 2050 °C, KY sapphire tubes maintain structural stability under extreme thermal cycling and high-temperature environments. -

Excellent Mechanical Strength

Sapphire’s Mohs hardness of 9 ensures superior wear resistance, scratch resistance, and long service life compared to quartz or alumina tubes. -

Broad Optical Transmission

KY sapphire tubes offer high transmission from UV to IR (≈190 nm–5 μm), making them ideal for optical windows, protective sleeves, and laser-related applications. -

Chemical Inertness

Highly resistant to acids, alkalis, and corrosive gases, KY sapphire tubes perform reliably in aggressive chemical and plasma environments.

Typical Applications

-

Semiconductor Equipment

Used as process tubes, protective sleeves, and insulating components in epitaxy, diffusion, and plasma systems. -

High-Temperature Furnaces

Ideal for thermocouple protection tubes, sight tubes, and insulation components exposed to extreme heat. -

Optical & Laser Systems

Applied in optical guides, lamp envelopes, laser protection tubes, and optical isolation components. -

Analytical & Medical Instruments

Suitable for spectroscopy, analytical chambers, and specialized medical or laboratory equipment requiring transparency and durability. -

Industrial & Aerospace Applications

Used in harsh environments where high mechanical strength, thermal stability, and chemical resistance are essential.

Specification

| Parameter | Typical Value |

|---|---|

| Material | Single-crystal Al₂O₃ (Sapphire) |

| Purity | ≥ 99.99% |

| Outer Diameter | 0.5 mm – 200 mm |

| Inner Diameter | 0.2 mm – 180 mm |

| Length | up to 1200 mm |

| Transmission Range | 200–5000 nm |

| Working Temperature | up to 2000°C (vacuum/inert gas) |

| Hardness | 9 on Mohs scale |

FAQ

Q1: What is the main difference between KY sapphire tubes and EFG sapphire tubes?

A: KY sapphire tubes are machined from bulk single-crystal sapphire grown by the Kyropoulos method, offering higher crystal quality and lower internal stress, while EFG sapphire tubes are directly shaped during growth and are more suitable for cost-sensitive applications.

Q2: Are KY sapphire tubes suitable for optical applications?

A: Yes. Due to their excellent optical uniformity and wide transmission range, KY sapphire tubes are well suited for high-end optical and laser-related applications.

Q3: Can KY sapphire tubes be used in high-temperature environments?

A: Absolutely. KY sapphire tubes maintain excellent stability and mechanical strength at elevated temperatures, even under repeated thermal cycling.

Q4: Are custom sizes available?

A: Yes. KY sapphire tubes can be custom-manufactured according to drawings or specific application requirements.

About Us

XKH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.