Silicon Carbide (SiC) MOSFETs are high-performance power semiconductor devices that have become essential in industries ranging from electric vehicles and renewable energy to industrial automation. Compared to traditional silicon (Si) MOSFETs, SiC MOSFETs offer superior performance under extreme conditions, including high temperatures, voltages, and frequencies. However, achieving optimal performance in SiC devices goes beyond simply acquiring high-quality substrates and epitaxial layers—it requires meticulous design and advanced manufacturing processes. This article provides an in-depth exploration of the design structure and manufacturing processes that enable high-performance SiC MOSFETs.

1. Chip Structure Design: Precise Layout for High Efficiency

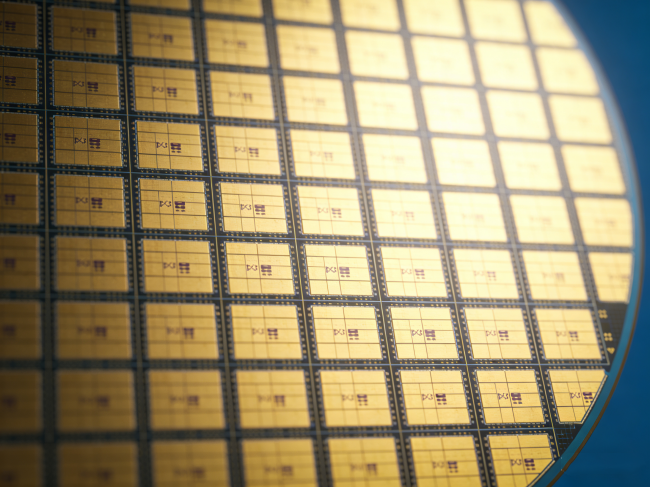

The design of SiC MOSFETs begins with the layout of the SiC wafer, which is the foundation for all device characteristics. A typical SiC MOSFET chip consists of several critical components on its surface, including:

-

Source Pad

-

Gate Pad

-

Kelvin Source Pad

The Edge Termination Ring (or Pressure Ring) is another important feature located around the chip’s periphery. This ring helps improve the breakdown voltage of the device by mitigating the concentration of the electric field at the edges of the chip, thus preventing leakage currents and enhancing device reliability. Typically, the Edge Termination Ring is based on a Junction Termination Extension (JTE) structure, which uses deep doping to optimize the electric field distribution and improve the breakdown voltage of the MOSFET.

2. Active Cells: Core of Switching Performance

The Active Cells in a SiC MOSFET are responsible for current conduction and switching. These cells are arranged in parallel, with the number of cells directly affecting the overall on-resistance (Rds(on)) and short-circuit current capacity of the device. To optimize performance, the distance between cells (known as the “cell pitch”) is reduced, improving the overall conduction efficiency.

Active cells can be designed in two primary structural forms: planar and trench structures. The planar structure, while simpler and more reliable, has limitations in performance due to cell spacing. In contrast, trench structures allow for higher density cell arrangements, reducing Rds(on) and enabling higher current handling. While trench structures are gaining popularity due to their superior performance, planar structures still offer a high degree of reliability and are continuing to be optimized for specific applications.

3. JTE Structure: Improving Voltage Blocking

The Junction Termination Extension (JTE) structure is a key design feature in SiC MOSFETs. JTE improves the voltage-blocking capability of the device by controlling the electric field distribution at the chip’s edges. This is crucial for preventing premature breakdown at the edge, where high electric fields are often concentrated.

The effectiveness of JTE depends on several factors:

-

JTE Region Width and Doping Level: The width of the JTE region and the concentration of dopants determine the electric field distribution at the device edges. A wider and more heavily doped JTE region can reduce the electric field and enhance breakdown voltage.

-

JTE Cone Angle and Depth: The angle and depth of the JTE cone influence the electric field distribution and ultimately affect the breakdown voltage. A smaller cone angle and deeper JTE region help in reducing electric field strength, thus improving the device’s ability to withstand higher voltages.

-

Surface Passivation: The surface passivation layer plays a vital role in reducing surface leakage currents and enhancing breakdown voltage. A well-optimized passivation layer ensures that the device performs reliably even at high voltages.

Thermal management is another crucial consideration in JTE design. SiC MOSFETs are capable of operating at higher temperatures than their silicon counterparts, but excessive heat can degrade device performance and reliability. As a result, thermal design, including heat dissipation and minimizing thermal stress, is critical in ensuring long-term device stability.

4. Switching Losses and Conduction Resistance: Performance Optimization

In SiC MOSFETs, conduction resistance (Rds(on)) and switching losses are two key factors determining overall efficiency. While Rds(on) governs the efficiency of current conduction, switching losses occur during the transitions between on and off states, contributing to heat generation and energy loss.

To optimize these parameters, several design factors need to be considered:

-

Cell Pitch: The pitch, or spacing between active cells, plays a significant role in determining the Rds(on) and switching speed. Reducing the pitch allows for higher cell density and lower conduction resistance, but the relationship between pitch size and gate reliability must also be balanced to avoid excessive leakage currents.

-

Gate Oxide Thickness: The thickness of the gate oxide layer affects the gate capacitance, which in turn influences switching speed and Rds(on). A thinner gate oxide increases switching speed but also raises the risk of gate leakage. Therefore, finding the optimal gate oxide thickness is essential for balancing speed and reliability.

-

Gate Resistance: The resistance of the gate material affects both switching speed and the overall conduction resistance. By integrating gate resistance directly into the chip, module design becomes more streamlined, reducing complexity and potential failure points in the packaging process.

5. Integrated Gate Resistance: Simplifying Module Design

In some SiC MOSFET designs, integrated gate resistance is used, which simplifies the module design and manufacturing process. By eliminating the need for external gate resistors, this approach reduces the number of components required, cuts down on manufacturing costs, and improves the reliability of the module.

The inclusion of gate resistance directly on the chip provides several benefits:

-

Simplified Module Assembly: Integrated gate resistance simplifies the wiring process and reduces the risk of failure.

-

Cost Reduction: Eliminating external components reduces the bill of materials (BOM) and overall manufacturing costs.

-

Enhanced Packaging Flexibility: The integration of gate resistance allows for more compact and efficient module designs, leading to improved space utilization in final packaging.

6. Conclusion: A Complex Design Process for Advanced Devices

Designing and manufacturing SiC MOSFETs involves a complex interplay of numerous design parameters and manufacturing processes. From optimizing the chip layout, active cell design, and JTE structures, to minimizing conduction resistance and switching losses, each element of the device must be finely tuned to achieve the best possible performance.

With continuous advancements in design and manufacturing technology, SiC MOSFETs are becoming increasingly efficient, reliable, and cost-effective. As the demand for high-performance, energy-efficient devices grows, SiC MOSFETs are poised to play a key role in powering the next generation of electrical systems, from electric vehicles to renewable energy grids and beyond.

Post time: Dec-08-2025