In GaN-based light-emitting diodes (LEDs), continuous progress in epitaxial growth techniques and device architecture has driven the internal quantum efficiency (IQE) increasingly close to its theoretical maximum. Despite these advances, the overall luminous performance of LEDs remains fundamentally limited by light extraction efficiency (LEE). As sapphire continues to be the predominant substrate material for GaN epitaxy, its surface morphology plays a decisive role in governing optical losses within the device.

This article presents a comprehensive comparison between flat sapphire substrates and patterned sapphire substrates (PSS). It elucidates the optical and crystallographic mechanisms through which PSS enhances light extraction efficiency and explains why PSS has become a de facto standard in high-performance LED manufacturing.

1. Light Extraction Efficiency as a Fundamental Bottleneck

The external quantum efficiency (EQE) of an LED is determined by the product of two primary factors:

EQE=IQE×LEE

While IQE quantifies the efficiency of radiative recombination within the active region, LEE describes the fraction of generated photons that successfully escape the device.

For GaN-based LEDs grown on sapphire substrates, LEE in conventional designs is typically limited to approximately 30–40%. This limitation arises primarily from:

-

Severe refractive index mismatch among GaN (n ≈ 2.4), sapphire (n ≈ 1.7), and air (n ≈ 1.0)

-

Strong total internal reflection (TIR) at planar interfaces

-

Photon trapping within the epitaxial layers and the substrate

Consequently, a significant portion of generated photons undergo multiple internal reflections and are ultimately absorbed by the material or converted into heat rather than contributing to useful light output.

2. Flat Sapphire Substrates: Structural Simplicity with Optical Constraints

2.1 Structural Characteristics

Flat sapphire substrates typically employ a c-plane (0001) orientation with a smooth, planar surface. They have been widely adopted due to:

-

High crystalline quality

-

Excellent thermal and chemical stability

-

Mature and cost-effective manufacturing processes

2.2 Optical Behavior

From an optical standpoint, planar interfaces lead to highly directional and predictable photon propagation paths. When photons generated in the GaN active region reach the GaN–air or GaN–sapphire interface at incident angles exceeding the critical angle, total internal reflection occurs.

This results in:

-

Strong photon confinement within the device

-

Increased absorption by metal electrodes and defect states

-

A restricted angular distribution of emitted light

In essence, flat sapphire substrates offer little assistance in overcoming optical confinement.

3. Patterned Sapphire Substrates: Concept and Structural Design

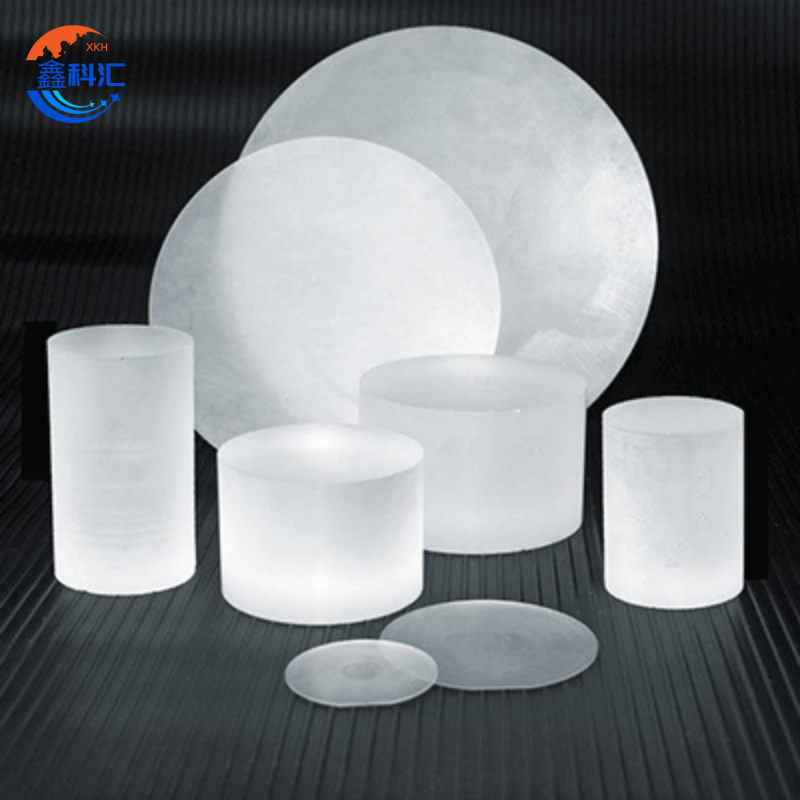

A patterned sapphire substrate (PSS) is formed by introducing periodic or quasi-periodic micro- or nanoscale structures onto the sapphire surface using photolithography and etching techniques.

Common PSS geometries include:

-

Conical structures

-

Hemispherical domes

-

Pyramidal features

-

Cylindrical or truncated-cone shapes

Typical feature dimensions range from sub-micrometer to several micrometers, with carefully controlled height, pitch, and duty cycle.

4. Mechanisms of Light Extraction Enhancement in PSS

4.1 Suppression of Total Internal Reflection

The three-dimensional topography of PSS modifies the local angles of incidence at material interfaces. Photons that would otherwise experience total internal reflection at a flat boundary are redirected into angles within the escape cone, substantially increasing their probability of exiting the device.

4.2 Enhanced Optical Scattering and Path Randomization

PSS structures introduce multiple refraction and reflection events, leading to:

-

Randomization of photon propagation directions

-

Increased interaction with light-extraction interfaces

-

Reduced photon residence time within the device

Statistically, these effects enhance the likelihood of photon extraction before absorption occurs.

4.3 Effective Refractive Index Grading

From an optical modeling perspective, PSS acts as an effective refractive index transition layer. Rather than an abrupt refractive index change from GaN to air, the patterned region provides a gradual refractive index variation, thereby reducing Fresnel reflection losses.

This mechanism is conceptually analogous to anti-reflection coatings, although it relies on geometric optics rather than thin-film interference.

4.4 Indirect Reduction of Optical Absorption Losses

By shortening photon path lengths and suppressing repeated internal reflections, PSS reduces the probability of optical absorption by:

-

Metal contacts

-

Crystal defect states

-

Free-carrier absorption in GaN

These effects contribute to both higher efficiency and improved thermal performance.

5. Additional Benefits: Improvement in Crystal Quality

Beyond optical enhancement, PSS also improves epitaxial material quality through lateral epitaxial overgrowth (LEO) mechanisms:

-

Dislocations originating at the sapphire–GaN interface are redirected or terminated

-

Threading dislocation density is significantly reduced

-

Improved crystal quality enhances device reliability and operational lifetime

This dual optical and structural benefit distinguishes PSS from purely optical surface-texturing approaches.

6. Quantitative Comparison: Flat Sapphire vs. PSS

| Parameter | Flat Sapphire Substrate | Patterned Sapphire Substrate |

|---|---|---|

| Surface topology | Planar | Micro-/nano-patterned |

| Light scattering | Minimal | Strong |

| Total internal reflection | Dominant | Strongly suppressed |

| Light extraction efficiency | Baseline | +20% to +40% (typical) |

| Dislocation density | Higher | Lower |

| Process complexity | Low | Moderate |

| Cost | Lower | Higher |

Actual performance gains depend on pattern geometry, emission wavelength, chip architecture, and packaging strategy.

7. Trade-offs and Engineering Considerations

Despite its advantages, PSS introduces several practical challenges:

-

Additional lithography and etching steps increase fabrication cost

-

Pattern uniformity and etch depth require precise control

-

Poorly optimized patterns may adversely affect epitaxial uniformity

Therefore, PSS optimization is inherently a multidisciplinary task involving optical simulation, epitaxial growth engineering, and device design.

8. Industry Perspective and Future Outlook

In modern LED manufacturing, PSS is no longer regarded as an optional enhancement. In medium- and high-power LED applications—including general illumination, automotive lighting, and display backlighting—it has become a baseline technology.

Future research and development trends include:

-

Advanced PSS designs tailored for Mini-LED and Micro-LED applications

-

Hybrid approaches combining PSS with photonic crystals or nanoscale surface texturing

-

Continued efforts toward cost reduction and scalable patterning technologies

Conclusion

Patterned sapphire substrates represent a fundamental transition from passive mechanical supports to functional optical and structural components in LED devices. By addressing light extraction losses at their root—namely optical confinement and interface reflection—PSS enables higher efficiency, improved reliability, and more consistent device performance.

In contrast, while flat sapphire substrates remain attractive due to their manufacturability and lower cost, their inherent optical limitations restrict their suitability for next-generation high-efficiency LEDs. As LED technology continues to evolve, PSS stands as a clear example of how materials engineering can directly translate into system-level performance gains.

Post time: Jan-30-2026