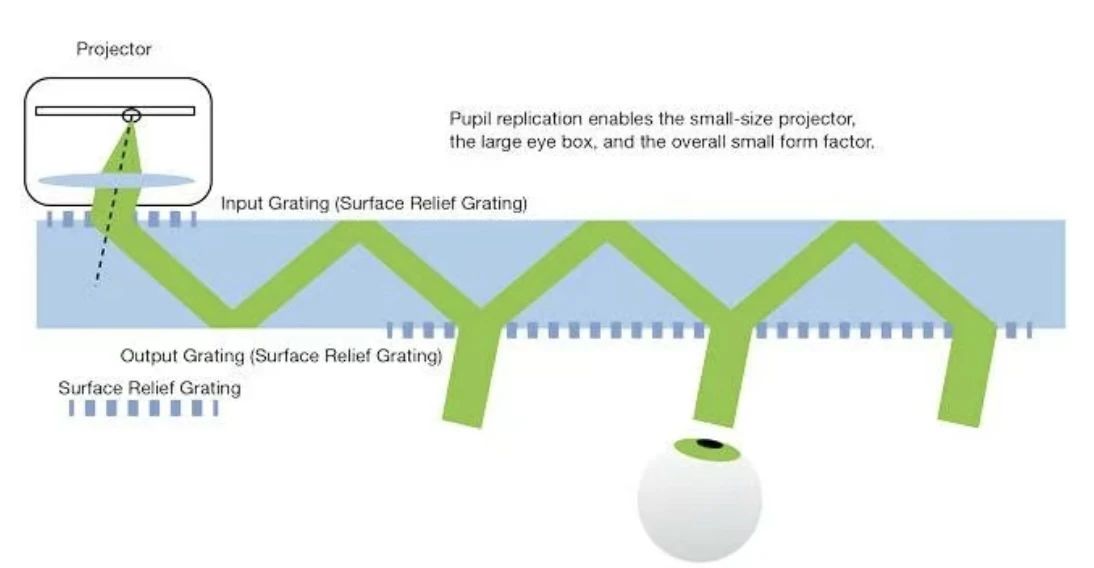

Against the backdrop of the AI revolution, AR glasses are gradually entering public consciousness. As a paradigm that seamlessly blends virtual and real worlds, AR glasses differ from VR devices by allowing users to perceive both digitally projected images and ambient environmental light simultaneously. To achieve this dual functionality—projecting microdisplay images into the eyes while preserving external light transmission—optical-grade silicon carbide (SiC)-based AR glasses employ a waveguide (lightguide) architecture. This design leverages total internal reflection to transmit images, analogous to optical fiber transmission, as illustrated in the schematic diagram.

Typically, one 6-inch high-purity semi-insulating substrate can yield 2 pairs of glasses, while an 8-inch substrate accommodates 3–4 pairs. The adoption of SiC materials confers three critical advantages:

- Exceptional refractive index (2.7): Enables >80° full-color field of view (FOV) with a single lens layer, eliminating rainbow artifacts common in conventional AR designs.

- Integrated tri-color (RGB) waveguide: Replaces multi-layer waveguide stacks, reducing device size and weight.

- Superior thermal conductivity (490 W/m·K): Mitigates heat accumulation-induced optical degradation.

These merits have driven strong market demand for SiC-based AR glasses. The optical-grade SiC used typically consists of high-purity semi-insulating (HPSI) crystals, whose stringent preparation requirements contribute to current high costs. Consequently, the development of HPSI SiC substrates is pivotal.

1. Synthesis of Semi-Insulating SiC Powder

Industrial-scale production predominantly utilizes high-temperature self-propagating synthesis (SHS), a process demanding meticulous control:

- Raw materials: 99.999% pure carbon/silicon powders with particle sizes of 10–100 μm.

- Crucible purity: Graphite components undergo high-temperature purification to minimize metallic impurity diffusion.

- Atmosphere control: 6N-purity argon (with in-line purifiers) suppresses nitrogen incorporation; trace HCl/H₂ gases may be introduced to volatilize boron compounds and reduce nitrogen, though H₂ concentration requires optimization to prevent graphite corrosion.

- Equipment standards: Synthesis furnaces must achieve <10⁻⁴ Pa base vacuum, with rigorous leak-checking protocols.

2. Crystal Growth Challenges

HPSI SiC growth shares similar purity requirements:

- Feedstock: 6N+-purity SiC powder with B/Al/N <10¹⁶ cm⁻³, Fe/Ti/O below threshold limits, and minimal alkali metals (Na/K).

- Gas systems: 6N argon/hydrogen blends enhance resistivity.

- Equipment: Molecular pumps ensure ultrahigh vacuum (<10⁻⁶ Pa); crucible pre-treatment and nitrogen purging are critical.

2.1 Substrate Processing Innovations

Compared to silicon, SiC’s prolonged growth cycles and inherent stress (causing cracking/edge chipping) necessitate advanced processing:

- Laser slicing: Increases yield from 30 wafers (350 μm, wire saw) to >50 wafers per 20-mm boule, with potential for 200-μm thinning. Processing time drops from 10–15 days (wire saw) to <20 min/wafer for 8-inch crystals.

3. Industry Collaborations

Meta’s Orion team has pioneered optical-grade SiC waveguide adoption, spurring R&D investments. Key partnerships include:

- TankeBlue & MUDI Micro: Joint development of AR diffractive waveguide lenses.

- Jingsheng Mech, Longqi Tech, XREAL, & Kunyou Optoelectronics: Strategic alliance for AI/AR supply chain integration.

Market projections estimate 500,000 SiC-based AR units annually by 2027, consuming 250,000 6-inch (or 125,000 8-inch) substrates. This trajectory underscores SiC’s transformative role in next-generation AR optics.

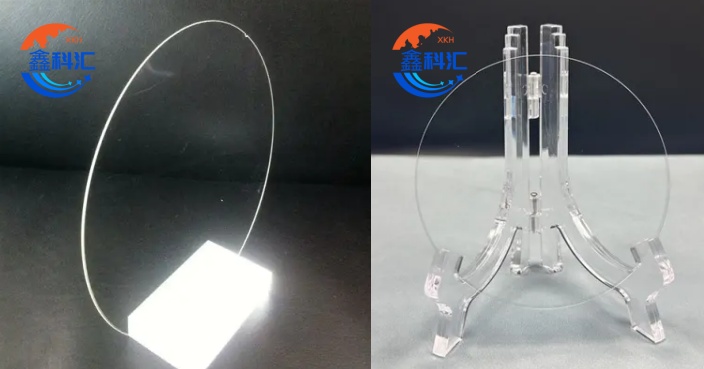

XKH specialize in supplying high-quality 4H-semi-insulating (4H-SEMI) SiC substrates with customizable diameters ranging from 2-inch to 8-inch, tailored to meet specific application requirements in RF, power electronics, and AR/VR optics. Our strengths include reliable volume supply, precision customization (thickness, orientation, surface finish), and full in-house processing from crystal growth to polishing. Beyond 4H-SEMI, we also offer 4H-N-type, 4H/6H-P-type, and 3C-SiC substrates, supporting diverse semiconductor and optoelectronic innovations.

Post time: Aug-08-2025