Introduction

Sapphire substrates play a foundational role in modern semiconductor manufacturing, particularly in optoelectronics and wide-bandgap device applications. As a single-crystal form of aluminum oxide (Al₂O₃), sapphire offers a unique combination of mechanical hardness, thermal stability, chemical inertness, and optical transparency. These properties have made sapphire substrates indispensable for gallium nitride epitaxy, LED fabrication, laser diodes, and a range of emerging compound semiconductor technologies.

However, not all sapphire substrates are created equal. The performance, yield, and reliability of downstream semiconductor processes are highly sensitive to substrate quality. Factors such as crystal orientation, thickness uniformity, surface roughness, and defect density directly influence epitaxial growth behavior and device performance. This article examines what defines a high-quality sapphire substrate for semiconductor applications, with particular emphasis on crystal orientation, total thickness variation (TTV), surface roughness, epitaxial compatibility, and common quality issues encountered in manufacturing and application.

Sapphire Substrate Fundamentals

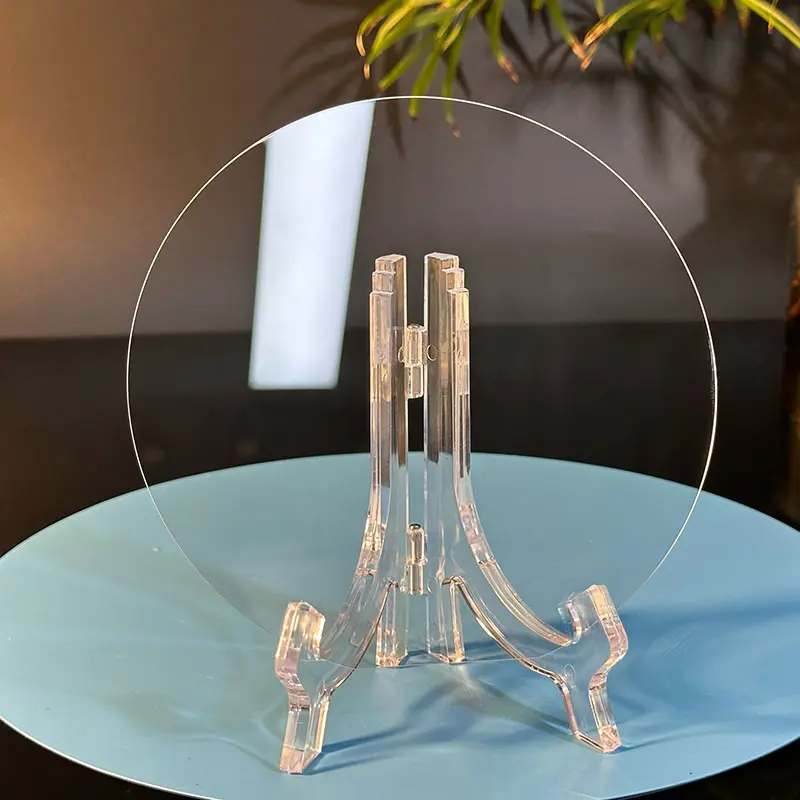

A sapphire substrate is a single-crystal aluminum oxide wafer produced through crystal growth techniques such as the Kyropoulos, Czochralski, or Edge-Defined Film-Fed Growth (EFG) methods. Once grown, the crystal boule is oriented, sliced, lapped, polished, and inspected to produce semiconductor-grade sapphire wafers.

In semiconductor contexts, sapphire is primarily valued for its insulating properties, high melting point, and structural stability under high-temperature epitaxial growth. Unlike silicon, sapphire does not conduct electricity, making it ideal for applications where electrical isolation is critical, such as LED devices and RF components.

The suitability of a sapphire substrate for semiconductor use depends not only on bulk crystal quality but also on precise control of geometric and surface parameters. These attributes must be engineered to meet increasingly stringent process requirements.

Crystal Orientation and Its Impact

Crystal orientation is one of the most critical parameters defining sapphire substrate quality. Sapphire is an anisotropic crystal, meaning its physical and chemical properties vary depending on crystallographic direction. The orientation of the substrate surface relative to the crystal lattice strongly affects epitaxial film growth, stress distribution, and defect formation.

The most commonly used sapphire orientations in semiconductor applications include c-plane (0001), a-plane (11-20), r-plane (1-102), and m-plane (10-10). Among these, c-plane sapphire is the dominant choice for LED and GaN-based devices due to its compatibility with conventional metal-organic chemical vapor deposition processes.

Precise orientation control is essential. Even small miscuts or angular deviations can significantly alter surface step structures, nucleation behavior, and strain relaxation mechanisms during epitaxy. High-quality sapphire substrates typically specify orientation tolerances within fractions of a degree, ensuring consistency across wafers and between production batches.

Orientation Uniformity and Epitaxial Consequences

Uniform crystal orientation across the wafer surface is as important as the nominal orientation itself. Variations in local orientation can lead to non-uniform epitaxial growth rates, thickness variation in deposited films, and spatial variations in defect density.

For LED manufacturing, orientation-induced variations can translate into non-uniform emission wavelength, brightness, and efficiency across a wafer. In high-volume production, such non-uniformities directly impact binning efficiency and overall yield.

Advanced semiconductor sapphire wafers are therefore characterized not only by their nominal plane designation but also by tight control of orientation uniformity across the entire wafer diameter.

Total Thickness Variation (TTV) and Geometric Precision

Total thickness variation, commonly referred to as TTV, is a key geometric parameter that defines the difference between the maximum and minimum thickness of a wafer. In semiconductor processing, TTV directly affects wafer handling, lithography focus depth, and epitaxial uniformity.

Low TTV is particularly important for automated manufacturing environments where wafers are transported, aligned, and processed with minimal mechanical tolerance. Excessive thickness variation can cause wafer bowing, improper chucking, and focus errors during photolithography.

High-quality sapphire substrates typically require TTV values tightly controlled to a few micrometers or less, depending on wafer diameter and application. Achieving such precision demands careful control of slicing, lapping, and polishing processes, as well as rigorous metrology and quality assurance.

Relationship Between TTV and Wafer Flatness

While TTV describes thickness variation, it is closely related to wafer flatness parameters such as bow and warp. Sapphire’s high stiffness and hardness make it less forgiving than silicon when it comes to geometric imperfections.

Poor flatness combined with high TTV can lead to localized stress during high-temperature epitaxial growth, increasing the risk of cracking or slip. In LED production, these mechanical issues may result in wafer breakage or degraded device reliability.

As wafer diameters increase, controlling TTV and flatness becomes more challenging, further emphasizing the importance of advanced polishing and inspection techniques.

Surface Roughness and Its Role in Epitaxy

Surface roughness is a defining characteristic of semiconductor-grade sapphire substrates. The atomic-scale smoothness of the substrate surface has a direct impact on epitaxial film nucleation, defect density, and interface quality.

In GaN epitaxy, surface roughness influences the formation of initial nucleation layers and the propagation of dislocations into the epitaxial film. Excessive roughness can lead to increased threading dislocation density, surface pits, and non-uniform film growth.

High-quality sapphire substrates for semiconductor applications typically require surface roughness values measured in fractions of a nanometer, achieved through advanced chemical mechanical polishing techniques. These ultra-smooth surfaces provide a stable foundation for high-quality epitaxial layers.

Surface Damage and Subsurface Defects

Beyond measurable roughness, subsurface damage introduced during slicing or grinding can significantly affect substrate performance. Micro-cracks, residual stress, and amorphous surface layers may not be visible through standard surface inspection but can act as defect initiation sites during high-temperature processing.

Thermal cycling during epitaxy can exacerbate these hidden defects, leading to wafer cracking or delamination of epitaxial layers. High-quality sapphire wafers therefore undergo optimized polishing sequences designed to remove damaged layers and restore crystalline integrity near the surface.

Epitaxial Compatibility and LED Application Requirements

The primary semiconductor application for sapphire substrates remains GaN-based LEDs. In this context, substrate quality directly affects device efficiency, lifetime, and manufacturability.

Epitaxial compatibility involves not only lattice matching but also thermal expansion behavior, surface chemistry, and defect management. While sapphire is not lattice-matched to GaN, careful control of substrate orientation, surface condition, and buffer layer design allows for high-quality epitaxial growth.

For LED applications, uniform epitaxial thickness, low defect density, and consistent emission properties across the wafer are critical. These outcomes are closely tied to substrate parameters such as orientation accuracy, TTV, and surface roughness.

Thermal Stability and Process Compatibility

LED epitaxy and other semiconductor processes often involve temperatures exceeding 1,000 degrees Celsius. Sapphire’s exceptional thermal stability makes it well suited for such environments, but substrate quality still plays a role in how the material responds to thermal stress.

Variations in thickness or internal stress can lead to non-uniform thermal expansion, increasing the risk of wafer bowing or cracking. High-quality sapphire substrates are engineered to minimize internal stress and ensure consistent thermal behavior across the wafer.

Common Quality Issues in Sapphire Substrates

Despite advances in crystal growth and wafer processing, several quality issues remain common in sapphire substrates. These include orientation misalignment, excessive TTV, surface scratches, polishing-induced damage, and internal crystal defects such as inclusions or dislocations.

Another frequent issue is wafer-to-wafer variability within the same batch. Inconsistent process control during slicing or polishing can lead to variations that complicate downstream process optimization.

For semiconductor manufacturers, these quality issues translate into increased process tuning requirements, lower yields, and higher overall production costs.

Inspection, Metrology, and Quality Control

Ensuring sapphire substrate quality requires comprehensive inspection and metrology. Orientation is verified using X-ray diffraction or optical methods, while TTV and flatness are measured using contact or optical profilometry.

Surface roughness is typically characterized using atomic force microscopy or white-light interferometry. Advanced inspection systems may also detect subsurface damage and internal defects.

High-quality sapphire substrate suppliers integrate these measurements into strict quality control workflows, providing traceability and consistency essential for semiconductor manufacturing.

Future Trends and Increasing Quality Demands

As LED technology evolves toward higher efficiency, smaller device dimensions, and advanced architectures, the demands placed on sapphire substrates continue to increase. Larger wafer sizes, tighter tolerances, and lower defect densities are becoming standard requirements.

In parallel, emerging applications such as micro-LED displays and advanced optoelectronic devices impose even stricter requirements on substrate uniformity and surface quality. These trends are driving continuous innovation in crystal growth, wafer processing, and metrology.

Conclusion

A high-quality sapphire substrate is defined by far more than its basic material composition. Crystal orientation accuracy, low TTV, ultra-smooth surface roughness, and epitaxial compatibility collectively determine its suitability for semiconductor applications.

For LED and compound semiconductor manufacturing, the sapphire substrate serves as the physical and structural foundation upon which device performance is built. As process technologies advance and tolerances tighten, substrate quality becomes an increasingly critical factor in achieving high yield, reliability, and cost efficiency.

Understanding and controlling the key parameters discussed in this article is essential for any organization involved in the production or use of semiconductor sapphire wafers.

Post time: Dec-29-2025