The history of human technology can often be seen as a relentless pursuit of “enhancements”—external tools that amplify natural capabilities.

Fire, for example, served as an “add-on” digestive system, freeing more energy for brain development. Radio, born in the late 19th century, became an “external vocal cord,” allowing voices to travel at the speed of light across the globe.

Today, AR (Augmented Reality) is emerging as an “external eye”—bridging virtual and real worlds, transforming how we see our surroundings.

Yet despite early promise, AR’s evolution has lagged behind expectations. Some innovators are determined to accelerate this transformation.

On September 24, Westlake University, announced a key breakthrough in AR display technology.

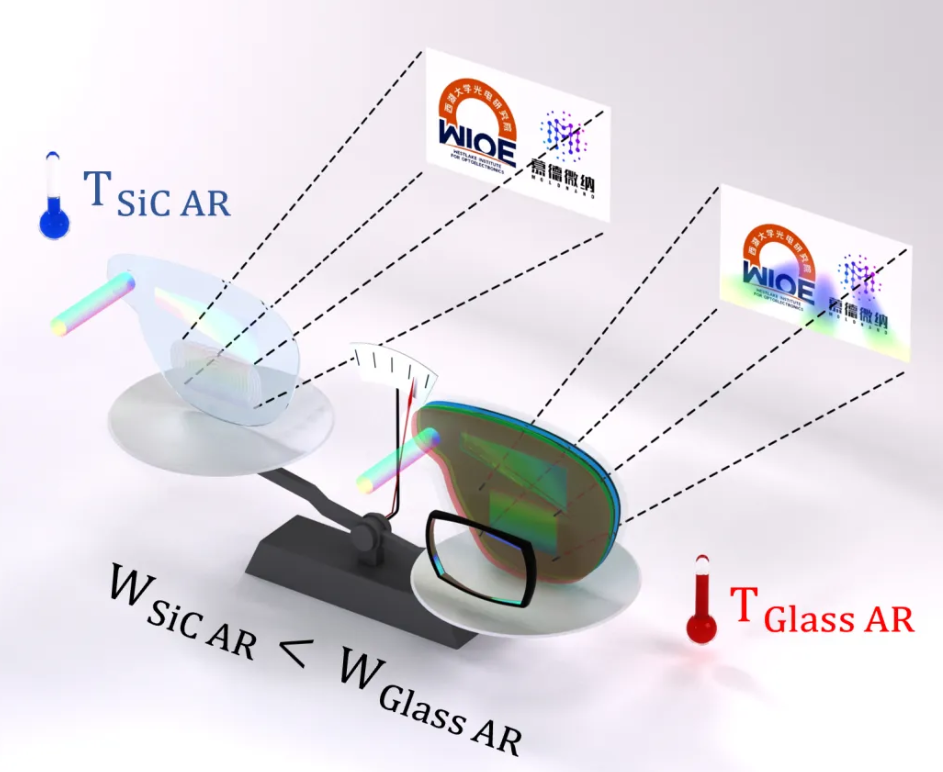

By replacing traditional glass or resin with silicon carbide (SiC), they developed ultra-thin and lightweight AR lenses—each weighing just 2.7 grams and only 0.55 mm thick—thinner than typical sunglasses. The new lenses also enable wide field-of-view (FOV) full-color display and eliminate the notorious “rainbow artifacts” that plague conventional AR glasses.

This innovation could reshape AR eyewear design and bring AR closer to mass consumer adoption.

The Power of Silicon Carbide

Why choose silicon carbide for AR lenses? The story begins in 1893, when French scientist Henri Moissan discovered a brilliant crystal in meteorite samples from Arizona—made of carbon and silicon. Known today as Moissanite, this gem-like material is loved for its higher refractive index and brilliance compared to diamonds.

In the mid-20th century, SiC also emerged as a next-generation semiconductor. Its superior thermal and electrical properties have made it invaluable in electric vehicles, communications equipment, and solar cells.

Compared to silicon devices (300°C max), SiC components operate at up to 600°C with 10x higher frequency and much greater energy efficiency. Its high thermal conductivity also aids in rapid cooling.

Naturally rare—mainly found in meteorites—artificial SiC production is difficult and costly. Growing a mere 2 cm crystal requires a 2300°C furnace running for seven days. Post-growth, the material’s diamond-like hardness makes cutting and processing a challenge.

In fact, the original focus of Prof. Qiu Min’s lab at Westlake University was to solve exactly this problem—developing laser-based techniques to efficiently slice SiC crystals, dramatically improving yield and lowering costs.

During this process, the team also noticed another unique property of pure SiC: an impressive refractive index of 2.65 and optical clarity when undoped—ideal for AR optics.

The Breakthrough: Diffractive Waveguide Technology

At Westlake University’s Nanophotonics and Instrumentation Lab, a team of optics specialists began exploring how to leverage SiC in AR lenses.

In diffractive waveguide-based AR, a miniature projector on the side of the glasses emits light through a carefully engineered path. Nano-scale gratings on the lens diffract and guide the light, reflecting it multiple times before directing it precisely into the wearer’s eyes.

Previously, due to low refractive index of glass (around 1.5–2.0), traditional waveguides required multiple stacked layers—resulting in thick, heavy lenses and undesirable visual artifacts like “rainbow patterns” caused by environmental light diffraction. Protective outer layers further added to lens bulk.

With SiC’s ultra-high refractive index (2.65), a single waveguide layer is now sufficient for full-color imaging with an FOV exceeding 80°—double the capabilities of conventional materials. This dramatically enhances immersion and image quality for gaming, data visualization, and professional applications.

Moreover, precise grating designs and ultra-fine processing reduce distracting rainbow effects. Combined with SiC’s exceptional thermal conductivity, the lenses can even help dissipate heat generated by AR components—solving another challenge in compact AR glasses.

Rethinking the Rules of AR Design

Interestingly, this breakthrough began with a simple question from Prof. Qiu: “Does the 2.0 refractive index limit really hold?”

For years, industry convention assumed refractive indices above 2.0 would cause optical distortion. By challenging this belief and leveraging SiC, the team unlocked new possibilities.

Now, the prototype SiC AR glasses—lightweight, thermally stable, with crystal-clear full-color imaging—are ready to disrupt the market.

The Future

In a world where AR will soon reshape how we view reality, this story of turning a rare “space-born gem” into high-performance optical technology is a testament to human ingenuity.

From a substitute for diamonds to a breakthrough material for next-gen AR, silicon carbide is truly lighting the way forward.

About Us

We are XKH, a leading manufacturer specializing in Silicon Carbide (SiC) wafers and SiC crystals.

With advanced production capabilities and years of expertise, we supply high-purity SiC materials for next-generation semiconductors, optoelectronics, and emerging AR/VR technologies.

In addition to industrial applications, XKH also produces premium Moissanite gemstones (synthetic SiC), widely used in fine jewelry for their exceptional brilliance and durability.

Whether for power electronics, advanced optics, or luxury jewelry, XKH delivers reliable, high-quality SiC products to meet the evolving needs of global markets.

Post time: Jun-23-2025