Table of Contents

1.Heat Dissipation Bottleneck in AI Chips and the Breakthrough of Silicon Carbide Materials

2.Characteristics and Technical Advantages of Silicon Carbide Substrates

3.Strategic Plans and Collaborative Development by NVIDIA and TSMC

4.Implementation Path and Key Technical Challenges

5.Market Prospects and Capacity Expansion

6.Impact on the Supply Chain and Performance of Related Companies

7.Broad Applications and Overall Market Size of Silicon Carbide

8.XKH’s Customized Solutions and Product Support

The heat dissipation bottleneck of future AI chips is being overcome by silicon carbide (SiC) substrate materials.

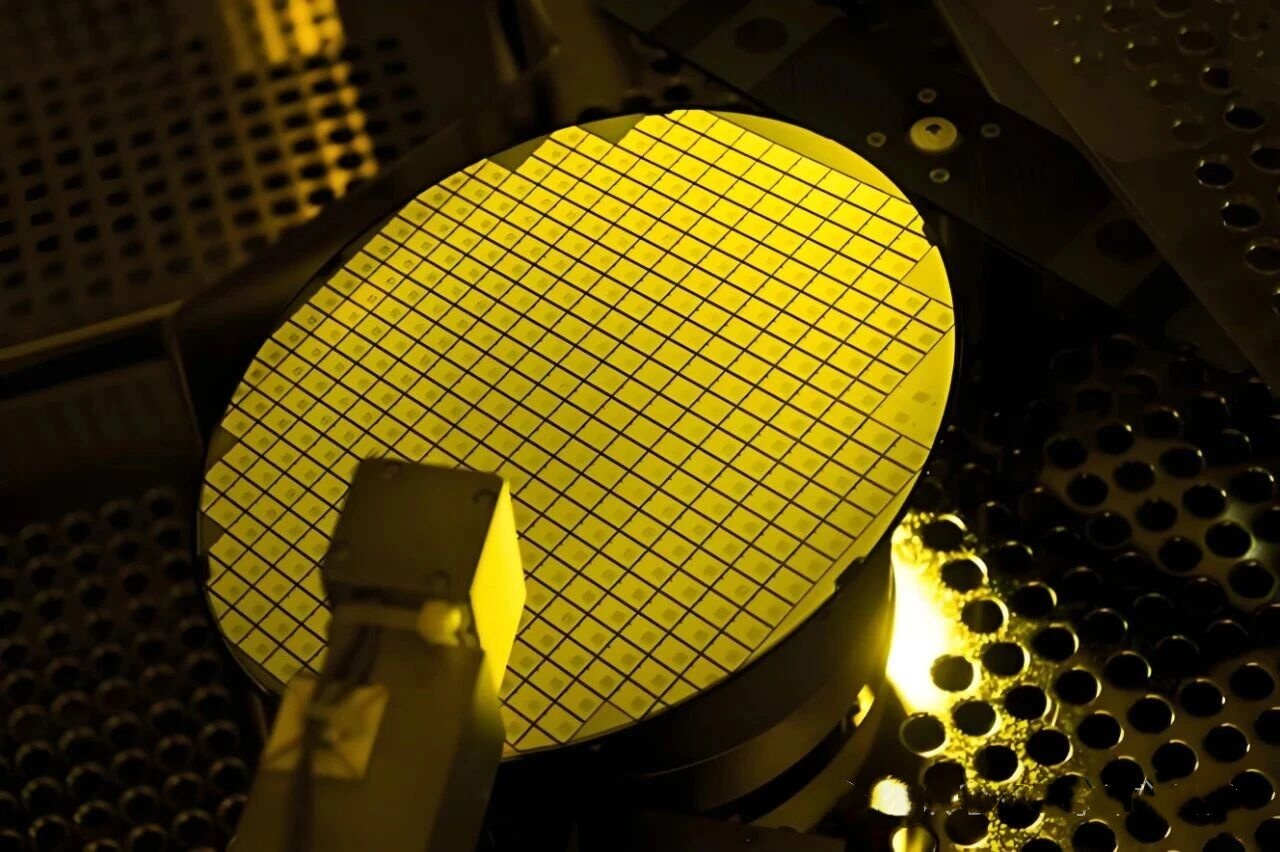

According to foreign media reports, NVIDIA plans to replace the intermediate substrate material in the CoWoS advanced packaging process of its next-generation processors with silicon carbide. TSMC has invited major manufacturers to jointly develop manufacturing technologies for SiC intermediate substrates.

The primary reason is that the performance improvement of current AI chips has encountered physical limitations. As GPU power increases, integrating multiple chips into silicon interposers generates extremely high heat dissipation demands. The heat generated within chips is approaching its limit, and traditional silicon interposers cannot effectively address this challenge.

NVIDIA Processors Switch Heat Dissipation Materials! Silicon Carbide Substrate Demand Set to Explode!Silicon carbide is a wide bandgap semiconductor, and its unique physical properties give it significant advantages in extreme environments with high power and high heat flux. In GPU advanced packaging, it offers two core advantages:

1.Heat Dissipation Capability: Replacing silicon interposers with SiC interposers can reduce thermal resistance by nearly 70%.

2.Efficient Power Architecture: SiC enables the creation of more efficient, smaller voltage regulator modules, significantly shortening power delivery paths, reducing circuit losses, and providing faster, more stable dynamic current responses for AI computing loads.

This transformation aims to address the heat dissipation challenges caused by continuously increasing GPU power, providing a more efficient solution for high-performance computing chips.

The thermal conductivity of silicon carbide is 2-3 times higher than that of silicon, effectively improving thermal management efficiency and solving heat dissipation problems in high-power chips. Its excellent thermal performance can reduce the junction temperature of GPU chips by 20-30°C, significantly enhancing stability in high-computing scenarios.

Implementation Path and Challenges

According to supply chain sources, NVIDIA will implement this material transformation in two steps:

•2025-2026: The first-generation Rubin GPU will still use silicon interposers. TSMC has invited major manufacturers to jointly develop SiC interposer manufacturing technology.

•2027: SiC interposers will be officially integrated into the advanced packaging process.

However, this plan faces many challenges, particularly in manufacturing processes. The hardness of silicon carbide is comparable to that of diamond, requiring extremely high cutting technology. If cutting technology is inadequate, the SiC surface may become wavy, rendering it unusable for advanced packaging. Equipment manufacturers such as Japan’s DISCO are working to develop new laser cutting equipment to address this challenge.

Future Prospects

Currently, SiC interposer technology will first be used in the most advanced AI chips. TSMC plans to launch a 7x reticle CoWoS in 2027 to integrate more processors and memory, increasing the interposer area to 14,400 mm², which will drive greater demand for substrates.

Morgan Stanley predicts that the global monthly CoWoS packaging capacity will surge from 38,000 12-inch wafers in 2024 to 83,000 in 2025 and 112,000 in 2026. This growth will directly boost demand for SiC interposers.

Although 12-inch SiC substrates are currently expensive, prices are expected to gradually decline to reasonable levels as mass production scales up and technology matures, creating conditions for large-scale applications.

SiC interposers not only solve heat dissipation problems but also significantly improve integration density. The area of 12-inch SiC substrates is nearly 90% larger than that of 8-inch substrates, allowing a single interposer to integrate more Chiplet modules, directly supporting NVIDIA’s 7x reticle CoWoS packaging requirements.

TSMC is collaborating with Japanese companies like DISCO to develop SiC interposer manufacturing technology. Once new equipment is in place, SiC interposer manufacturing will proceed more smoothly, with the earliest entry into advanced packaging expected in 2027.

Driven by this news, SiC-related stocks performed strongly on September 5, with the index rising 5.76%. Companies like Tianyue Advanced, Luxshare Precision, and Tiantong Co. hit the daily limit-up, while Jingsheng Mechanical & Electrical and Yintang Intelligent Control surged over 10%.

According to the Daily Economic News, to enhance performance, NVIDIA plans to replace the intermediate substrate material in the CoWoS advanced packaging process with silicon carbide in its next-generation Rubin processor development blueprint.

Public information shows that silicon carbide possesses excellent physical properties. Compared to silicon devices, SiC devices offer advantages such as high power density, low power loss, and exceptional high-temperature stability. According to Tianfeng Securities, the SiC industry chain upstream involves the preparation of SiC substrates and epitaxial wafers; the midstream includes the design, manufacturing, and packaging/testing of SiC power devices and RF devices.

Downstream, SiC applications are extensive, covering over ten industries, including new energy vehicles, photovoltaics, industrial manufacturing, transportation, communication base stations, and radar. Among these, automotive will become the core application field for SiC. According to Aijian Securities, by 2028, the automotive sector will account for 74% of the global power SiC device market.

In terms of overall market size, according to Yole Intelligence, the global conductive and semi-insulating SiC substrate market sizes were 512millionand242 million, respectively, in 2022. It is projected that by 2026, the global SiC market size will reach 2.053billion,withconductiveandsemi−insulatingSiCsubstratemarketsizesreaching1.62 billion and $433 million, respectively. The compound annual growth rates (CAGRs) for conductive and semi-insulating SiC substrates from 2022 to 2026 are expected to be 33.37% and 15.66%, respectively.

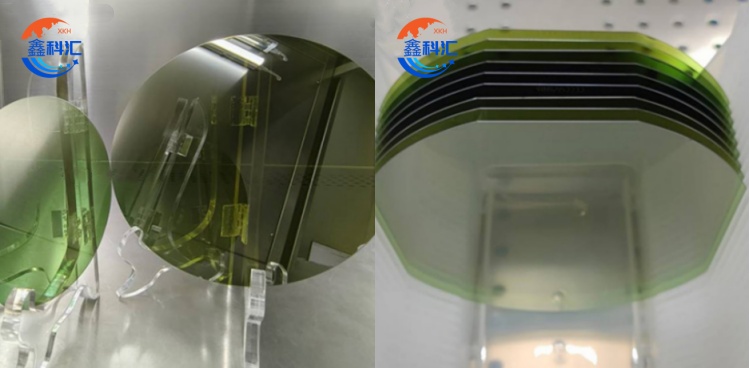

XKH Specializes in Customized Development and Global Sales of Silicon Carbide (SiC) Products, offering a full size range of 2 to 12 inches for both conductive and semi-insulating silicon carbide substrates. We support personalized customization of parameters such as crystal orientation, resistivity (10⁻³–10¹⁰ Ω·cm), and thickness (350–2000μm). Our products are widely used in high-end fields including new energy vehicles, photovoltaic inverters, and industrial motors. Leveraging a robust supply chain system and a technical support team, we ensure rapid response and precise delivery, helping customers enhance device performance and optimize system costs.

Post time: Sep-12-2025