High-purity silicon carbide (SiC) ceramics have emerged as ideal materials for critical components in semiconductor, aerospace, and chemical industries due to their exceptional thermal conductivity, chemical stability, and mechanical strength. With increasing demands for high-performance, low-pollution ceramic devices, the development of efficient and scalable preparation technologies for high-purity SiC ceramics has become a global research focus. This paper systematically reviews current major preparation methods for high-purity SiC ceramics, including recrystallization sintering, pressureless sintering (PS), hot pressing (HP), spark plasma sintering (SPS), and additive manufacturing (AM), with emphasis on discussing the sintering mechanisms, key parameters, material properties, and existing challenges of each process.

The application of SiC ceramics in the military and engineering fields

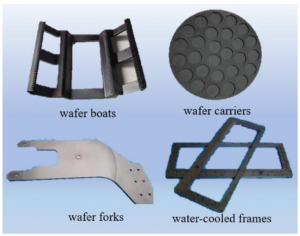

Currently, high-purity SiC ceramic components are widely used in silicon wafer manufacturing equipment, participating in core processes such as oxidation, lithography, etching, and ion implantation. With the advancement of wafer technology, increasing wafer sizes have become a significant trend. The current mainstream wafer size is 300 mm, achieving a good balance between cost and production capacity. However, driven by Moore’s Law, the mass production of 450 mm wafers is already on the agenda. Larger wafers typically require higher structural strength to resist warping and deformation, further driving the growing demand for large-size, high-strength, high-purity SiC ceramic components. In recent years, additive manufacturing (3D printing), as a rapid prototyping technology that requires no molds, has demonstrated tremendous potential in the fabrication of complex-structured SiC ceramic parts due to its layer-by-layer construction and flexible design capabilities, attracting widespread attention.

This paper will systematically analyze five representative preparation methods for high-purity SiC ceramics—recrystallization sintering, pressureless sintering, hot pressing, spark plasma sintering, and additive manufacturing—focusing on their sintering mechanisms, process optimization strategies, material performance characteristics, and industrial application prospects.

High-purity silicon carbide raw material requirements

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) is a high-purity SiC material prepared without sintering aids at high temperatures of 2100–2500°C. Since Fredriksson first discovered the recrystallization phenomenon in the late 19th century, RSiC has garnered significant attention due to its clean grain boundaries and absence of glass phases and impurities. At high temperatures, SiC exhibits relatively high vapor pressure, and its sintering mechanism primarily involves an evaporation-condensation process: fine grains evaporate and redeposit on the surfaces of larger grains, promoting neck growth and direct bonding between grains, thereby enhancing material strength.

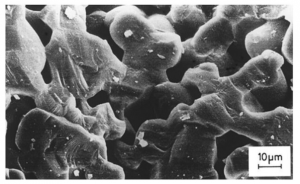

In 1990, Kriegesmann prepared RSiC with a relative density of 79.1% using slip casting at 2200°C, with the cross-section showing a microstructure composed of coarse grains and pores. Subsequently, Yi et al. used gel casting to prepare green bodies and sintered them at 2450°C, obtaining RSiC ceramics with a bulk density of 2.53 g/cm³ and a flexural strength of 55.4 MPa.

The SEM fracture surface of RSiC

Compared to dense SiC, RSiC has lower density (approximately 2.5 g/cm³) and about 20% open porosity, limiting its performance in high-strength applications. Therefore, improving the density and mechanical properties of RSiC has become a key research focus. Sung et al. proposed infiltrating molten silicon into carbon/β-SiC mixed compacts and recrystallizing at 2200°C, successfully constructing a network structure composed of α-SiC coarse grains. The resulting RSiC achieved a density of 2.7 g/cm³ and a flexural strength of 134 MPa, maintaining excellent mechanical stability at high temperatures.

To further enhance density, Guo et al. employed polymer infiltration and pyrolysis (PIP) technology for multiple treatments of RSiC. Using PCS/xylene solutions and SiC/PCS/xylene slurries as infiltrants, after 3–6 PIP cycles, the density of RSiC was significantly improved (up to 2.90 g/cm³), along with its flexural strength. Additionally, they proposed a cyclic strategy combining PIP and recrystallization: pyrolysis at 1400°C followed by recrystallization at 2400°C, effectively clearing particle blockages and reducing porosity. The final RSiC material achieved a density of 2.99 g/cm³ and a flexural strength of 162.3 MPa, demonstrating outstanding comprehensive performance.

SEM images of the microstructure evolution of polished RSiC after polymer impregnation and pyrolysis (PIP)-recrystallization cycles: Initial RSiC (A), after the first PIP-recrystallization cycle (B), and after the third cycle (C)

II. Pressureless Sintering

Pressureless-sintered silicon carbide (SiC) ceramics are typically prepared using high-purity, ultrafine SiC powder as raw material, with small amounts of sintering aids added, and sintered in an inert atmosphere or vacuum at 1800–2150°C. This method is suitable for producing large-size and complex-structured ceramic components. However, since SiC is primarily covalently bonded, its self-diffusion coefficient is extremely low, making densification difficult without sintering aids.

Based on the sintering mechanism, pressureless sintering can be divided into two categories: pressureless liquid-phase sintering (PLS-SiC) and pressureless solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC is typically sintered below 2000°C by adding approximately 10 wt.% of eutectic sintering aids (such as Al₂O₃, CaO, MgO, TiO₂, and rare-earth oxides RE₂O₃) to form a liquid phase, promoting particle rearrangement and mass transfer to achieve densification. This process is suitable for industrial-grade SiC ceramics, but there have been no reports of high-purity SiC achieved through liquid-phase sintering.

1.2 PSS-SiC (Solid-State Sintering)

PSS-SiC involves solid-state densification at temperatures above 2000°C with approximately 1 wt.% of additives. This process relies mainly on atomic diffusion and grain rearrangement driven by high temperatures to reduce surface energy and achieve densification. The B-C (boron-carbon) system is a common additive combination, which can lower grain boundary energy and remove SiO₂ from the SiC surface. However, traditional B-C additives often introduce residual impurities, reducing SiC purity.

By controlling additive content (B 0.4 wt.%, C 1.8 wt.%) and sintering at 2150°C for 0.5 hours, high-purity SiC ceramics with a purity of 99.6 wt.% and a relative density of 98.4% were obtained. The microstructure showed columnar grains (some exceeding 450 µm in length), with minor pores at grain boundaries and graphite particles inside grains. The ceramics exhibited a flexural strength of 443 ± 27 MPa, an elastic modulus of 420 ± 1 GPa, and a thermal expansion coefficient of 3.84 × 10⁻⁶ K⁻¹ in the range of room temperature to 600°C, demonstrating excellent overall performance.

Microstructure of PSS-SiC: (A) SEM image after polishing and NaOH etching; (B-D) BSD images after polishing and etching

III. Hot Pressing Sintering

Hot pressing (HP) sintering is a densification technique that simultaneously applies heat and uniaxial pressure to powder materials under high-temperature and high-pressure conditions. High pressure significantly inhibits pore formation and limits grain growth, while high temperature promotes grain fusion and the formation of dense structures, ultimately producing high-density, high-purity SiC ceramics. Due to the directional nature of pressing, this process tends to induce grain anisotropy, affecting mechanical and wear properties.

Pure SiC ceramics are difficult to densify without additives, requiring ultrahigh-pressure sintering. Nadeau et al. successfully prepared fully dense SiC without additives at 2500°C and 5000 MPa; Sun et al. obtained β-SiC bulk materials with a Vickers hardness of up to 41.5 GPa at 25 GPa and 1400°C. Using 4 GPa pressure, SiC ceramics with relative densities of approximately 98% and 99%, hardness of 35 GPa, and elastic modulus of 450 GPa were prepared at 1500°C and 1900°C, respectively. Sintering micron-sized SiC powder at 5 GPa and 1500°C yielded ceramics with a hardness of 31.3 GPa and a relative density of 98.4%.

Although these results demonstrate that ultrahigh pressure can achieve additive-free densification, the complexity and high cost of the required equipment limit industrial applications. Therefore, in practical preparation, trace additives or powder granulation are often used to enhance sintering driving force.

By adding 4 wt.% phenolic resin as an additive and sintering at 2350°C and 50 MPa, SiC ceramics with a densification rate of 92% and purity of 99.998% were obtained. Using low additive amounts (boric acid and D-fructose) and sintering at 2050°C and 40 MPa, high-purity SiC with a relative density >99.5% and residual B content of only 556 ppm was prepared. SEM images showed that, compared to pressureless-sintered samples, hot-pressed samples had smaller grains, fewer pores, and higher density. The flexural strength was 453.7 ± 44.9 MPa, and the elastic modulus reached 444.3 ± 1.1 GPa.

By extending the holding time at 1900°C, grain size increased from 1.5 μm to 1.8 μm, and thermal conductivity improved from 155 to 167 W·m⁻¹·K⁻¹, while also enhancing plasma corrosion resistance.

Under conditions of 1850°C and 30 MPa, hot pressing and rapid hot pressing of granulated and annealed SiC powder yielded fully dense β-SiC ceramics without any additives, with a density of 3.2 g/cm³ and a sintering temperature 150–200°C lower than traditional processes. The ceramics exhibited a hardness of 2729 GPa, fracture toughness of 5.25–5.30 MPa·m^1/2, and excellent creep resistance (creep rates of 9.9 × 10⁻¹⁰ s⁻¹ and 3.8 × 10⁻⁹ s⁻¹ at 1400°C/1450°C and 100 MPa).

(A) SEM image of the polished surface; (B) SEM image of the fracture surface; (C, D) BSD image of the polished surface

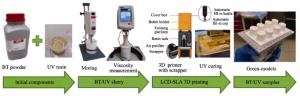

In 3D printing research for piezoelectric ceramics, ceramic slurry, as the core factor influencing forming and performance, has become a key focus domestically and internationally. Current studies generally indicate that parameters such as powder particle size, slurry viscosity, and solid content significantly affect the forming quality and piezoelectric properties of the final product.

Research has found that ceramic slurries prepared using micron-, submicron-, and nano-sized barium titanate powders exhibit significant differences in stereolithography (e.g., LCD-SLA) processes. As particle size decreases, slurry viscosity increases markedly, with nano-sized powders producing slurries with viscosities reaching billions of mPa·s. Slurries with micron-sized powders are prone to delamination and peeling during printing, while submicron and nano-sized powders demonstrate more stable forming behavior. After high-temperature sintering, the resulting ceramic samples achieved a density of 5.44 g/cm³, a piezoelectric coefficient (d₃₃) of approximately 200 pC/N, and low loss factors, exhibiting excellent electromechanical response properties.

Additionally, in micro-stereolithography processes, adjusting the solid content of PZT-type slurries (e.g., 75 wt.%) yielded sintered bodies with a density of 7.35 g/cm³, achieving a piezoelectric constant of up to 600 pC/N under poling electric fields. Research on micro-scale deformation compensation significantly improved forming accuracy, enhancing geometric precision by up to 80%.

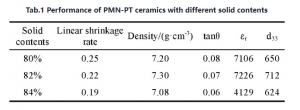

Another study on PMN-PT piezoelectric ceramics revealed that solid content critically influences ceramic structure and electrical properties. At 80 wt.% solid content, byproducts easily appeared in the ceramics; as solid content increased to 82 wt.% and above, byproducts gradually disappeared, and the ceramic structure became purer, with significantly improved performance. At 82 wt.%, the ceramics exhibited optimal electrical properties: a piezoelectric constant of 730 pC/N, relative permittivity of 7226, and dielectric loss of only 0.07.

In summary, particle size, solid content, and rheological properties of ceramic slurries not only affect the stability and accuracy of the printing process but also directly determine the density and piezoelectric response of sintered bodies, making them key parameters for achieving high-performance 3D-printed piezoelectric ceramics.

The main process of LCD-SLA 3D printing of BT/UV samples

The properties of PMN-PT ceramics with different solid contents

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) is an advanced sintering technology that utilizes pulsed current and mechanical pressure simultaneously applied to powders to achieve rapid densification. In this process, current directly heats the mold and powder, generating Joule heat and plasma, enabling efficient sintering in a short time (typically within 10 minutes). Rapid heating promotes surface diffusion, while spark discharge helps remove adsorbed gases and oxide layers from powder surfaces, improving sintering performance. The electromigration effect induced by electromagnetic fields also enhances atomic diffusion.

Compared to traditional hot pressing, SPS employs more direct heating, enabling densification at lower temperatures while effectively inhibiting grain growth to obtain fine and uniform microstructures. For example:

- Without additives, using ground SiC powder as raw material, sintering at 2100°C and 70 MPa for 30 minutes yielded samples with 98% relative density.

- Sintering at 1700°C and 40 MPa for 10 minutes produced cubic SiC with 98% density and grain sizes of only 30–50 nm.

- Using 80 µm granular SiC powder and sintering at 1860°C and 50 MPa for 5 minutes resulted in high-performance SiC ceramics with 98.5% relative density, Vickers microhardness of 28.5 GPa, flexural strength of 395 MPa, and fracture toughness of 4.5 MPa·m^1/2.

Microstructural analysis showed that as sintering temperature increased from 1600°C to 1860°C, material porosity decreased significantly, approaching full density at high temperatures.

The microstructure of SiC ceramics sintered at different temperatures: (A) 1600°C, (B) 1700°C, (C) 1790°C and (D) 1860°C

V. Additive Manufacturing

Additive manufacturing (AM) has recently demonstrated tremendous potential in fabricating complex ceramic components due to its layer-by-layer construction process. For SiC ceramics, multiple AM technologies have been developed, including binder jetting (BJ), 3DP, selective laser sintering (SLS), direct ink writing (DIW), and stereolithography (SL, DLP). However, 3DP and DIW have lower precision, while SLS tends to induce thermal stress and cracks. In contrast, BJ and SL offer greater advantages in producing high-purity, high-precision complex ceramics.

- Binder Jetting (BJ)

BJ technology involves layer-by-layer spraying of binder to bond powder, followed by debinding and sintering to obtain the final ceramic product. Combining BJ with chemical vapor infiltration (CVI), high-purity, fully crystalline SiC ceramics were successfully prepared. The process includes:

① Forming SiC ceramic green bodies using BJ.

② Densifying via CVI at 1000°C and 200 Torr.

③ The final SiC ceramic had a density of 2.95 g/cm³, thermal conductivity of 37 W/m·K, and flexural strength of 297 MPa.

Schematic diagram of adhesive jet (BJ) printing. (A) Computer-aided design (CAD) model, (B) schematic diagram of BJ principle, (C) printing of SiC by BJ, (D) densification of SiC by chemical vapor infiltration (CVI)

- Stereolithography (SL)

SL is a UV-curing-based ceramic forming technology with extremely high precision and complex structure fabrication capabilities. This method uses photosensitive ceramic slurries with high solid content and low viscosity to form 3D ceramic green bodies through photopolymerization, followed by debinding and high-temperature sintering to obtain the final product.

Using a 35 vol.% SiC slurry, high-quality 3D green bodies were prepared under 405 nm UV irradiation and further densified via polymer burnout at 800°C and PIP treatment. Results showed that samples prepared with 35 vol.% slurry achieved a relative density of 84.8%, outperforming 30% and 40% control groups.

By introducing lipophilic SiO₂ and phenolic epoxy resin (PEA) to modify the slurry, photopolymerization performance was effectively improved. After sintering at 1600°C for 4 h, near-complete conversion to SiC was achieved, with final oxygen content of only 0.12%, enabling one-step fabrication of high-purity, complex-structured SiC ceramics without pre-oxidation or pre-infiltration steps.

Illustration of the printing structure and its sintering process. The appearance of the sample after drying at (A) 25°C, pyrolysis at (B) 1000°C, and sintering at (C) 1600°C.

By designing photosensitive Si₃N₄ ceramic slurries for stereolithography 3D printing and employing debinding-presintering and high-temperature aging processes, Si₃N₄ ceramics with 93.3% theoretical density, tensile strength of 279.8 MPa, and flexural strength of 308.5–333.2 MPa were prepared. Studies found that under conditions of 45 vol.% solid content and 10 s exposure time, single-layer green bodies with IT77-level curing precision could be obtained. A low-temperature debinding process with a heating rate of 0.1 °C/min helped produce crack-free green bodies.

Sintering is a key step affecting final performance in stereolithography. Research shows that adding sintering aids can effectively improve ceramic density and mechanical properties. Using CeO₂ as a sintering aid and electric field-assisted sintering technology to prepare high-density Si₃N₄ ceramics, CeO₂ was found to segregate at grain boundaries, promoting grain boundary sliding and densification. The resulting ceramics exhibited Vickers hardness of HV10/10 (1347.9 ± 2.4) and fracture toughness of (6.57 ± 0.07) MPa·m¹/². With MgO–Y₂O₃ as additives, ceramic microstructure homogeneity was improved, significantly enhancing performance. At a total doping level of 8 wt.%, flexural strength and thermal conductivity reached 915.54 MPa and 59.58 W·m⁻¹·K⁻¹, respectively.

VI. Conclusion

In summary, high-purity silicon carbide (SiC) ceramics, as an outstanding engineering ceramic material, have demonstrated broad application prospects in semiconductors, aerospace, and extreme-condition equipment. This paper systematically analyzed five typical preparation routes for high-purity SiC ceramics—recrystallization sintering, pressureless sintering, hot pressing, spark plasma sintering, and additive manufacturing—with detailed discussions on their densification mechanisms, key parameter optimization, material performance, and respective advantages and limitations.

It is evident that different processes each have unique characteristics in terms of achieving high purity, high density, complex structures, and industrial feasibility. Additive manufacturing technology, in particular, has shown strong potential in fabricating complex-shaped and customized components, with breakthroughs in subfields like stereolithography and binder jetting, making it an important development direction for high-purity SiC ceramic preparation.

Future research on high-purity SiC ceramic preparation needs to delve deeper, promoting the transition from laboratory-scale to large-scale, highly reliable engineering applications, thereby providing critical material support for high-end equipment manufacturing and next-generation information technologies.

XKH is a high-tech enterprise specializing in the research and production of high-performance ceramic materials. It is dedicated to providing customized solutions for customers in the form of high-purity silicon carbide (SiC) ceramics. The company possesses advanced material preparation technologies and precise processing capabilities. Its business encompasses the research, production, precise processing, and surface treatment of high-purity SiC ceramics, meeting the stringent requirements of semiconductor, new energy, aerospace and other fields for high-performance ceramic components. Leveraging mature sintering processes and additive manufacturing technologies, we can offer customers a one-stop service from material formula optimization, complex structure formation to precise processing, ensuring that the products possess excellent mechanical properties, thermal stability and corrosion resistance.

Post time: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)