Table of Contents

1.Exceptional Properties of Sapphire Material: The Foundation for High-Performance Rigid Endoscopes

2.Innovative Single-Side Coating Technology: Achieving the Optimum Balance between Optical Performance and Clinical Safety

3.Stringent Processing and Coating Specifications: Ensuring Endoscope Reliability and Consistency

4.Comprehensive Advantages over Traditional Optical Glass: Why Sapphire is the High-End Choice

5.Clinical Validation and Future Evolution: From Practical Efficacy to the Technological Frontier

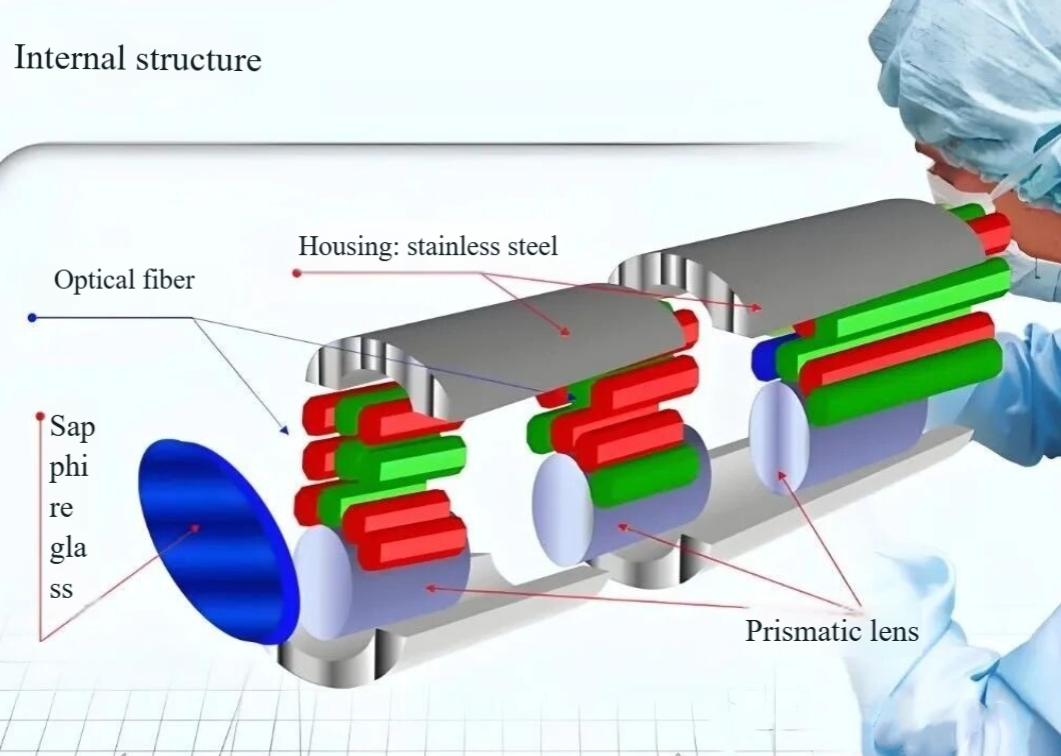

Sapphire (Al₂O₃), with a Mohs hardness of 9 (second only to diamond), a low coefficient of thermal expansion (5.3×10⁻⁶/K), and inherent inertness, possesses extremely stable physical and chemical properties along with broad-spectrum light transmission characteristics (0.15–5.5 μm). Supported by these excellent properties, sapphire has been widely adopted in recent years for manufacturing optical components in high-end rigid endoscopes, especially protective window covers or objective lens assemblies.

I. Core Advantages of Sapphire as a Material for Rigid Endoscopes

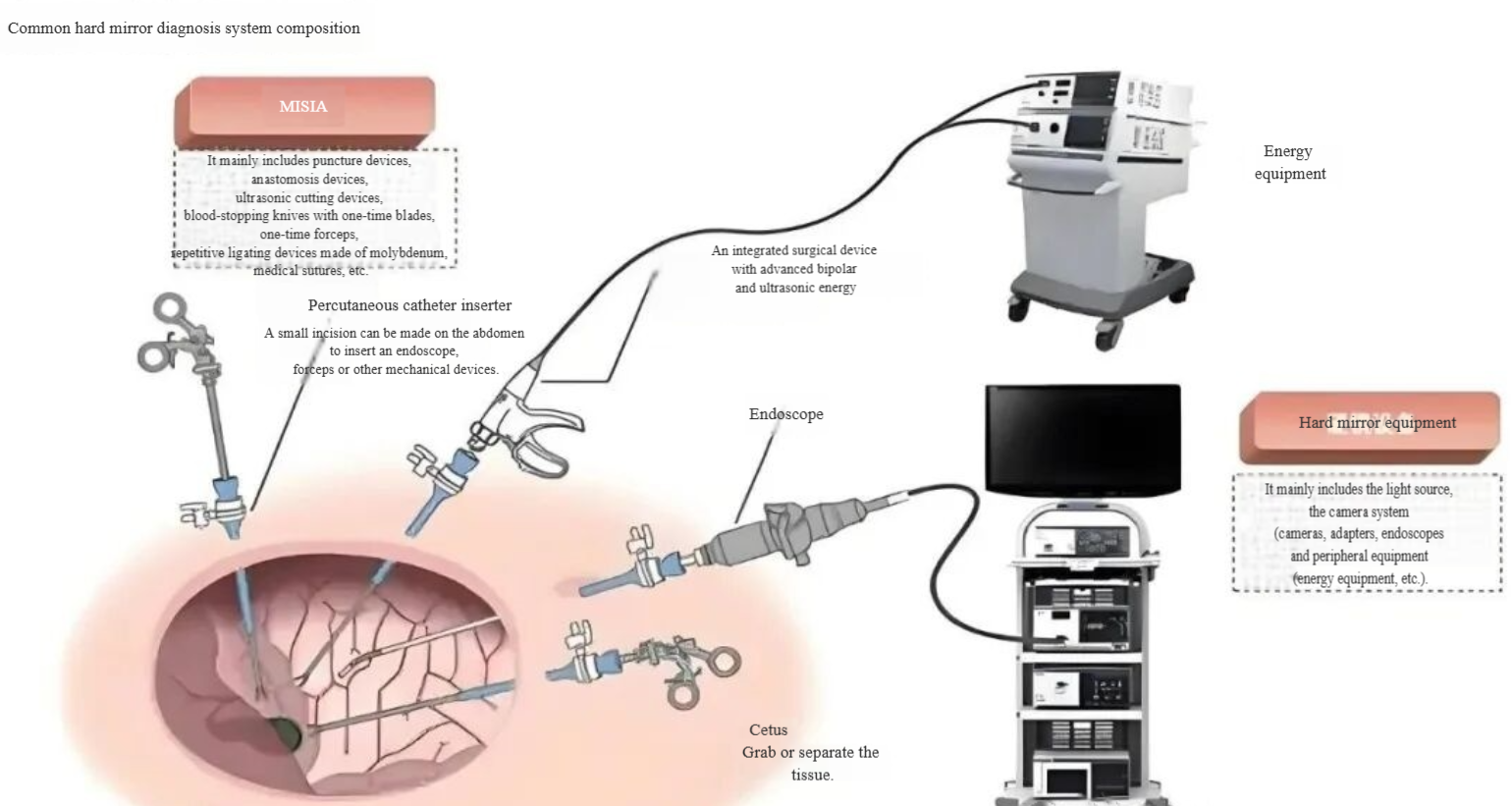

In biomedical applications, sapphire is frequently used as the primary substrate for optical components in high-end rigid endoscopes, particularly for protective windows or objective lenses. Its ultra-high hardness and wear resistance significantly reduce the risk of surface scratches during contact with tissue, prevent tissue abrasion caused by lens wear, and withstand long-term friction from surgical instruments (e.g., forceps, scissors), thereby extending the endoscope’s service life.

Sapphire exhibits excellent biocompatibility; it is a non-cytotoxic inert material with a highly smooth surface (achieving a roughness of Ra ≤ 0.5 nm after polishing), which reduces tissue adhesion and postoperative infection risks. This makes it easily compliant with the ISO 10993 medical device biocompatibility standard. Its unique resistance to high temperature and pressure, attributed to a low coefficient of thermal expansion (5.3×10⁻⁶/K), allows it to endure over 1000 cycles of high-pressure steam sterilization at 134°C without cracking or performance degradation.

Outstanding optical properties endow sapphire with a broad transmission range (0.15–5.5 μm). Its transmittance exceeds 85% in the visible light spectrum, ensuring sufficient imaging brightness. The high refractive index (1.76 @ 589 nm) enables a smaller lens curvature radius, facilitating the miniaturized design of endoscopes.

II. Coating Technology Design

In rigid endoscopes, single-side coating (typically applied to the side not contacting tissue) on sapphire components is an innovative design that balances performance and safety.

1.Optical Functional Optimization on the Coated Side

- Anti-Reflection (AR) Coating: Deposited on the inner surface of the lens (non-tissue contact side), it reduces reflectivity (single-surface reflectance < 0.2%), enhances light transmittance and image contrast, avoids cumulative tolerances from double-sided coating, and simplifies optical system calibration.

- Hydrophobic/Anti-Fog Coating: Prevents condensation on the inner lens surface during surgery, maintaining a clear field of view.

2.Safety Priority on the Non-Coated Side (Tissue Contact Side)

- Preservation of Sapphire’s Inherent Properties: Utilizes the native high smoothness and chemical stability of the sapphire surface, avoiding risks of coating peeling due to long-term contact with tissue or disinfectants. Eliminates potential biocompatibility controversies associated with coating materials (e.g., metal oxides) and human tissue.

- Simplified Maintenance Procedures: The non-coated side can directly contact potent disinfectants like alcohol and hydrogen peroxide without concern for coating corrosion.

III. Key Technical Indicators for Sapphire Component Processing and Coating

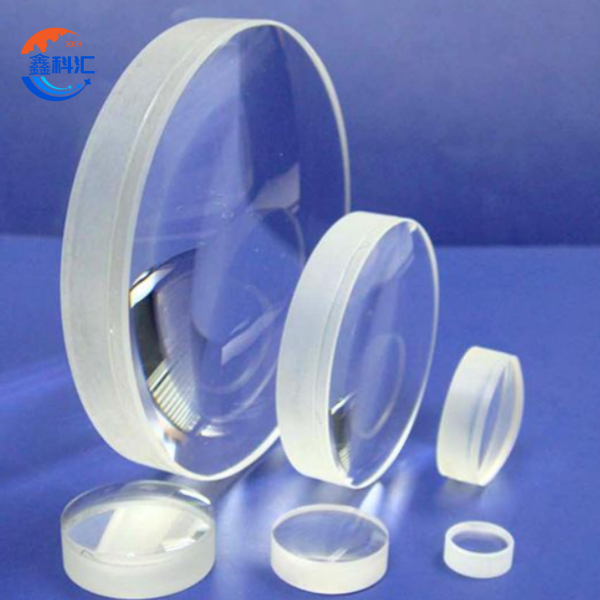

1.Sapphire Substrate Processing Requirements

- Geometric Accuracy: Diameter tolerance ≤ ±0.01 mm (common diameters for miniature rigid endoscopes are 3–5 mm).

- Flatness < λ/8 (λ = 632.8 nm), Eccentric Angle < 0.1°.

- Surface Quality: Roughness Ra ≤ 1 nm on the tissue contact surface to avoid micro-scratches causing tissue damage.

2.Single-Side Coating Process Standards

- Coating Adhesion: Passes ISO 2409 cross-cut test (Grade 0, no peeling).

- Sterilization Resistance: After 1000 high-pressure sterilization cycles, reflectance change of the coated surface is < 0.1%.

- Functional Coating Design: Anti-reflection coating should cover the 400–900 nm wavelength range, with single-surface transmittance > 99.5%.

IV. Comparative Analysis with Competitive Materials (e.g., Optical Glass)

The following table compares key properties of sapphire and traditional optical glass (like BK7):

|

Characteristic |

Sapphire |

Traditional Optical Glass (e.g., BK7) |

|

Hardness (Mohs) |

9 |

6–7 |

|

Scratch Resistance |

Extremely strong, virtually maintenance-free for life |

Requires hardening coating, periodic replacement |

|

Sterilization Tolerance |

Withstands >1000 high-pressure steam cycles |

Surface haze appears after about 300 cycles |

|

Tissue Contact Safety |

Direct contact with uncoated surface poses zero risk |

Relies on coating protection, posing potential peeling risks |

|

Cost |

High (approx. 3–5 times that of glass) |

Low |

V. Clinical Feedback and Improvement Directions

1.Practical Application Feedback

- Surgeon Evaluation: Sapphire rigid endoscopes significantly reduce lens blurring incidents in laparoscopic surgery, shortening operation time. The uncoated contact surface effectively prevents mucosal adhesion in ENT endoscope applications.

- Maintenance Cost: Repair rates for sapphire endoscopes are reduced by approximately 40%, although initial procurement costs are highe.

2.Technical Optimization Directions

- Composite Coating Technology: Superimposing AR and anti-static coatings on the non-contact side to reduce dust adhesion.

- Atypical Sapphire Processing: Developing beveled or curved sapphire protective windows to adapt to smaller diameter rigid endoscopes (< 2 mm).

Conclusion

Sapphire has become a core material for high-end rigid endoscopes due to its perfect balance of hardness, biosafety, and optical performance. The single-side coating design leverages coatings to enhance optical efficiency while preserving the native safety of the contact surface. This approach has proven to be a reliable solution meeting clinical needs. As sapphire processing costs decrease, its adoption in the endoscopy field is expected to grow further, driving minimally invasive surgical instruments toward greater safety and durability.

Post time: Oct-17-2025