Table of Contents

I. Core Functions of LiDAR Windows: Beyond Mere Protection

II. Material Comparison: The Performance Balance Between Fused Silica and Sapphire

III. Coating Technology: The Cornerstone Process for Enhancing Optical Performance

IV. Key Performance Parameters: Quantitative Evaluation Metrics

V. Application Scenarios: A Panorama from Autonomous Driving to Industrial Sensing

VI. Technological Evolution and Future Trends

In modern sensing technology, LiDAR (Light Detection and Ranging) acts as the “eyes” of machines, accurately perceiving the 3D world by emitting and receiving laser beams. These “eyes” require a transparent “protective lens” for safeguarding—this is the LiDAR Window Cover. It is not merely a piece of ordinary glass but a high-tech component integrating materials science, optical design, and precision engineering. Its performance directly determines the sensing accuracy, range, and overall reliability of LiDAR systems.

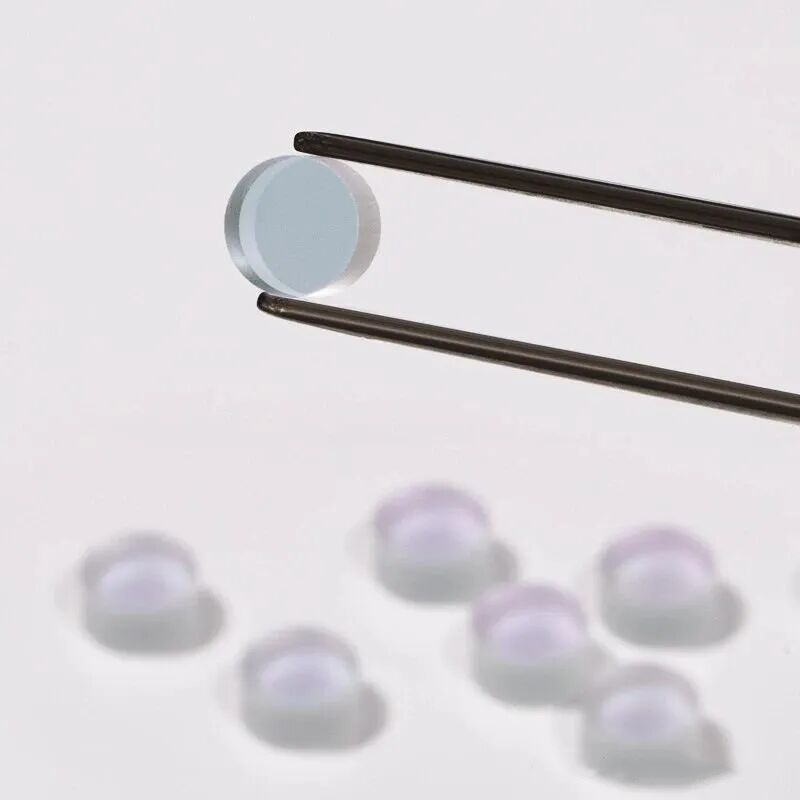

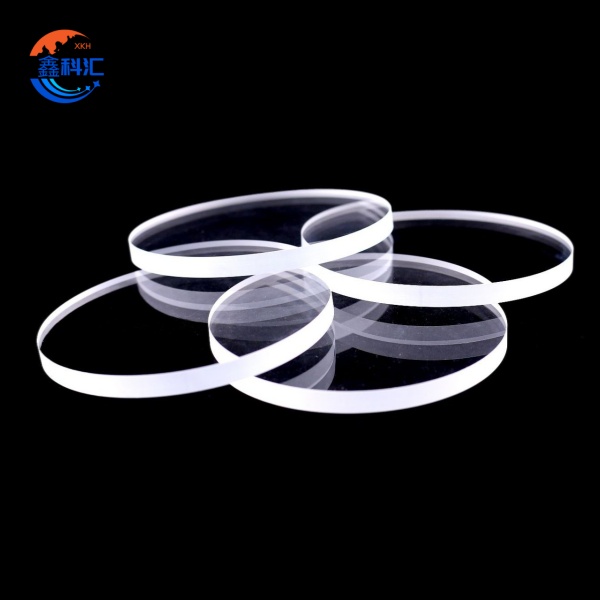

Optical Windows 1

I. Core Functions: Beyond “Protection”

The LiDAR window cover is an optical flat or spherical shield encapsulating the external part of the LiDAR sensor. Its key functions include:

- Physical Protection: Effectively isolates dust, moisture, oil, and even flying debris, safeguarding internal components (e.g., laser emitters, detectors, scanning mirrors).

- Environmental Sealing: As part of the housing, it forms an airtight seal with structural components to achieve required IP ratings (e.g., IP6K7/IP6K9K), ensuring stable operation in harsh conditions like rain, snow, and sandstorms.

- Optical Transmission: Its most critical function is allowing specific-wavelength lasers to pass through efficiently with minimal distortion. Any blockage, reflection, or aberration directly reduces ranging accuracy and point cloud quality.

Optical Windows 2

II. Mainstream Materials: The Battle of Glasses

Material choice dictates the performance ceiling of window covers. Industry mainstream uses glass-based materials, primarily two types:

1. Fused Silica Glass

- Characteristics: The absolute mainstream for automotive and industrial applications. Made of high-purity silica, it offers exceptional optical properties.

- Advantages:

- Excellent transmittance from UV to IR with ultra-low absorption.

- Low thermal expansion coefficient withstands extreme temperatures (-60°C to +200°C) without deformation.

- High hardness (Mohs ~7), resistant to abrasion from sand/wind.

- Applications: Autonomous vehicles, high-end industrial AGVs, surveying LiDAR.

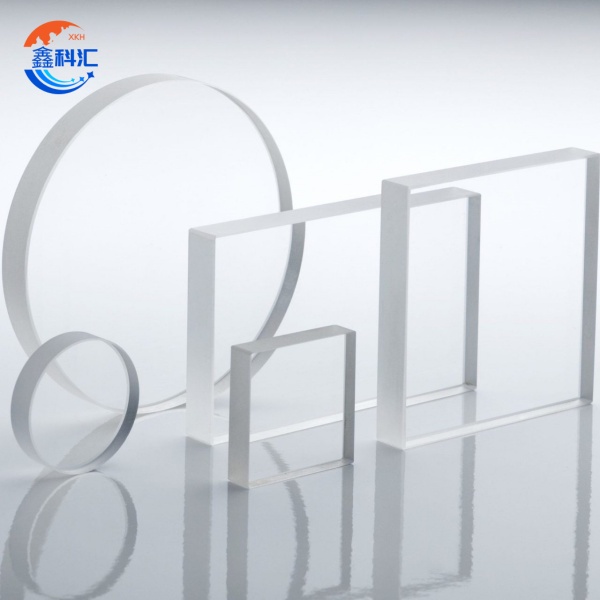

Sapphire step window pane

2. Sapphire Glass

- Characteristics: Synthetic single-crystal α-alumina, representing ultra-high performance.

- Advantages:

- Extreme hardness (Mohs ~9, second only to diamond), nearly scratch-proof.

- Balanced optical transmittance, high temperature resistance (melting point ~2040°C), and chemical stability.

- Challenges: High cost, difficult processing (requires diamond abrasives), and high density.

- Applications: High-end military, aerospace, and ultra-precision measurements.

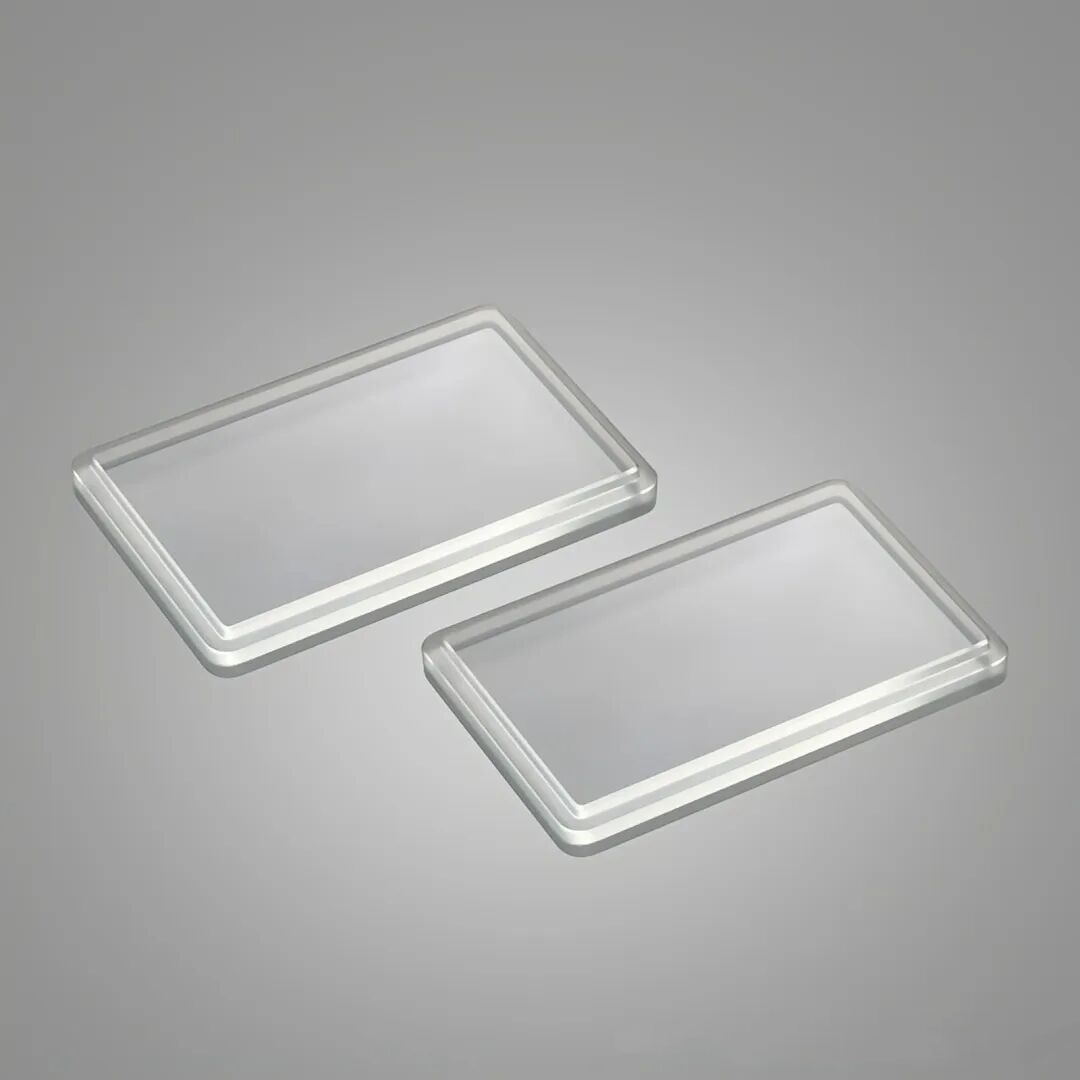

Double-sided anti-reflective window lens

III. Coating: The Core Technology That Turns Stone into Gold

Regardless of the substrate, coatings are essential to meet LiDAR’s stringent optical demands:

- Anti-Reflection (AR) Coating: The most critical layer. Deposited via vacuum coating (e.g., e-beam evaporation, magnetron sputtering), it reduces surface reflectance to <0.5% at target wavelengths, boosting transmittance from ~92% to >99.5%.

- Hydrophobic/Oleophobic Coating: Prevents water/oil adhesion, maintaining clarity in rain or contaminated environments.

- Other Functional Coatings: Heated demisting films (using ITO), anti-static layers, etc., for specialized needs.

Vacuum coating factory diagram

IV. Key Performance Parameters

When selecting or evaluating a LiDAR window cover, focus on these metrics:

- Transmittance @ Target Wavelength: The percentage of light transmitted at the LiDAR’s operating wavelength (e.g., >96% at 905nm/1550nm post-AR coating).

- Band Compatibility: Must match laser wavelengths (905nm/1550nm); reflectance should be minimized (<0.5%).

- Surface Figure Accuracy: Flatness and parallelism errors should be ≤λ/4 (λ = laser wavelength) to avoid beam distortion.

- Hardness & Wear Resistance: Measured by Mohs scale; critical for long-term durability.

- Environmental Endurance:

- Water/dust resistance: Minimum IP6K7 rating.

- Temperature cycling: Operational range typically -40°C to +85°C.

- UV/salt spray resistance to prevent degradation.

Vehicle-mounted LiDAR

V. Application Scenarios

Nearly all environmentally exposed LiDAR systems require window covers:

- Autonomous Vehicles: Mounted on rooftops, bumpers, or sides, facing direct exposure to weather and UV.

- Advanced Driver-Assistance Systems (ADAS): Integrated into vehicle bodies, requiring aesthetic harmony.

- Industrial AGVs/AMRs: Operating in warehouses/factories with dust and collision risks.

- Surveying & Remote Sensing: Airborne/vehicle-mounted systems enduring altitude changes and temperature fluctuations.

Conclusion

Though a simple physical component, the LiDAR window cover is crucial for ensuring clear and reliable “vision” for LiDAR. Its development hinges on a deep integration of material science, optics, coating processes, and environmental engineering. As the era of autonomous driving advances, this “window” will continue to evolve, safeguarding precise perception for machines.

Post time: Oct-17-2025